Description

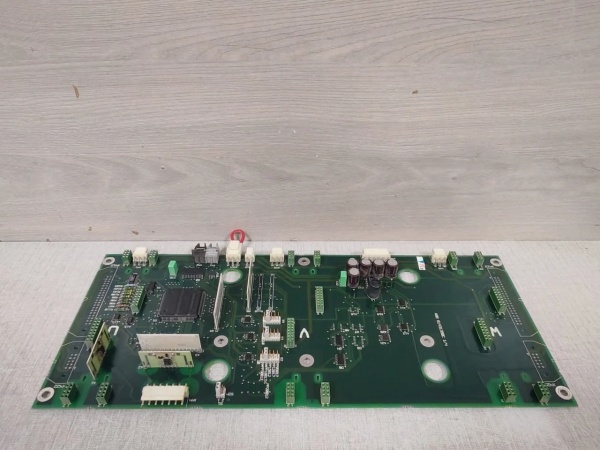

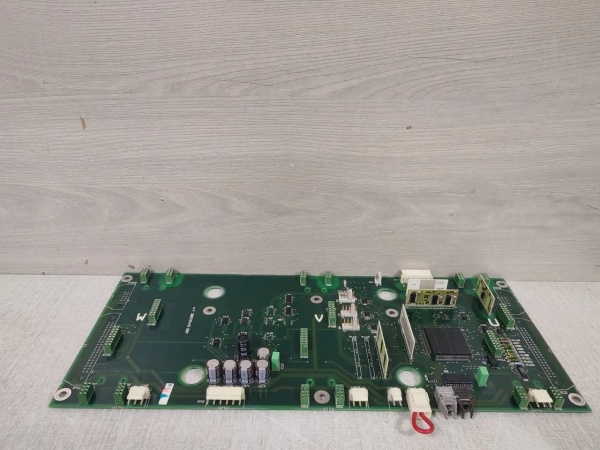

ABB NINT-71C: Product Overview

The ABB NINT-71C is a Profibus DP V1 slave interface module from the NINT Series, designed to integrate ABB S800 I/O systems into Profibus DP networks for industrial process automation. As a critical component in distributed control architectures, it enables bidirectional data exchange between field devices (via S800 I/O modules) and higher-level control systems (e.g., ABB AC 800M DCS, Siemens S7 PLCs), ensuring real-time monitoring and control of industrial processes.

The NINT Series is engineered for modularity and reliability, with the NINT-71C specifically optimized for Profibus DP V1 protocol. It supports advanced features like parameterization, diagnostics, and alarm handling, making it suitable for complex applications in power generation, chemical processing, and manufacturing. The module is typically mounted in S800 I/O stations, connecting to Profibus DP masters via shielded twisted-pair cables, and is compatible with ABB’s extensive portfolio of analog/digital I/O modules.

ABB NINT-71C

ABB NINT-71C: Technical Specifications

-

Model Number: NINT-71C

-

Manufacturer: ABB Ltd.

-

Product Type: Fieldbus Interface Module (Profibus DP Slave)

-

Protocol Support: Profibus DP V1 (conforms to IEC 61158-2)

-

Baud Rate: 9.6 kbps to 12 Mbps (auto-negotiation)

-

Data Exchange:

-

Input Data (Master → Slave): Up to 244 bytes

-

Output Data (Slave → Master): Up to 244 bytes

-

-

Power Supply: 24VDC (±20%, 0.5A max draw)

-

Operating Temperature: -40°C to +70°C (storage: -40°C to +85°C)

-

Relative Humidity: 5–95% non-condensing

-

Protection Rating: IP20 (panel-mounted, requires additional enclosure for harsh environments)

-

Dimensions: 45mm (H) x 100mm (W) x 120mm (D) (S800 I/O station-compatible)

-

Weight: ~0.3 kg (0.66 lbs)

-

Certifications: CE, UL/cUL Listed, RoHS, ATEX (optional for hazardous areas)

Core Features & Customer Value

-

Seamless Profibus DP Integration: The NINT-71C acts as a Profibus DP V1 slave, enabling direct communication with masters like ABB AC 800M, Siemens S7-1200/1500, and Schneider Modicon PLCs. This eliminates the need for protocol converters, reducing integration complexity and latency.

-

Advanced Diagnostics: Supports Profibus DP V1 diagnostics, including module status, communication errors, and field device alarms. Maintenance teams can quickly identify faults via the master system, minimizing downtime.

-

Modular Scalability: As part of the S800 I/O system, the NINT-71C allows expansion of I/O points (analog/digital) without reconfiguring the network. Engineers can add sensors/actuators incrementally, adapting to changing process needs.

-

Harsh Environment Resilience: With a -40°C to +70°C operating temperature range and robust design, the module withstands extreme conditions in power plants, offshore platforms, and chemical facilities. Optional ATEX certification enables use in explosive atmospheres.

-

Cost-Effective Redundancy: Supports redundant Profibus DP networks (when paired with dual NINT-71C modules), ensuring continuous communication in critical applications like turbine control or reactor monitoring.

ABB NINT-71C

Typical Applications

The ABB NINT-71C is widely used in process automation systems requiring Profibus DP connectivity:

-

Power Generation: Connects S800 I/O modules (e.g., analog inputs for turbine temperature sensors) to plant DCS for real-time monitoring.

-

Chemical Processing: Integrates distributed I/O stations (e.g., valve position feedback) into Profibus DP networks for batch control.

-

Water Treatment: Links remote sensor arrays (pH, flow meters) to central SCADA systems via S800 I/O and NINT-71C.

-

Manufacturing: Enables communication between robotic cells (via S800 I/O) and factory PLCs for synchronized motion control.