Description

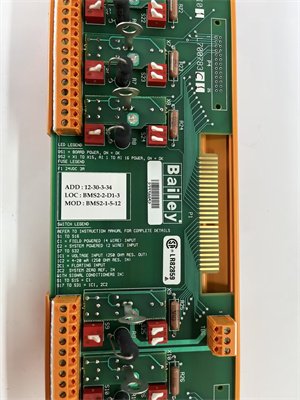

| Parameter name | Parameter value |

| Product model | NRAI01 |

| Manufacturer | ABB |

| Product category | Analog input module, part of ABB’s Advant OCS and Symphony Plus control systems, focused on precise signal acquisition |

| Input channels | 8 differential analog inputs |

| Input signal types | 4-20 mA, 0-20 mA, 0-10 VDC, thermocouples (Type J, K, T, E), RTDs (Pt100, Ni100) |

| Measurement accuracy | ±0.1% of full scale (for 4-20 mA); ±0.2°C (for Pt100 RTDs) |

| Isolation | Channel-to-bus: 2.5 kVAC; channel-to-channel: 1 kVAC |

| Sampling rate | 10 samples/second per channel, configurable up to 100 samples/second |

| Power supply | 24 VDC ±15%, 12 W max power consumption |

| Operating temperature | -25°C to +70°C (ambient); -40°C to +85°C (storage) |

| Dimensions (LxWxH) | 180 mm x 120 mm x 60 mm |

| Mounting type | DIN rail (35mm) or backplane mounting in ABB control cabinets |

| Protection class | IP20 with conformal coating (resistant to dust, moisture, and chemical vapors) |

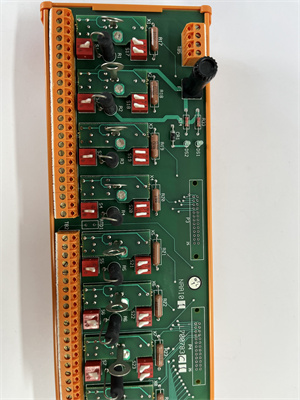

ABB NRAI01

Product introduction

The NRAI01 is a high-precision analog input module from ABB, designed to serve as a critical signal acquisition component in industrial control systems. As a key part of ABB’s Advant OCS and Symphony Plus ecosystems, it excels at converting physical process variables—such as temperature, pressure, and flow—into digital signals for processing by central controllers.

This module supports 8 differential analog inputs, accommodating a wide range of sensors including thermocouples, RTDs, and 4-20 mA transmitters. The NRAI01 ensures accurate data capture even in noisy industrial environments, thanks to its robust isolation and advanced filtering capabilities. By providing reliable, high-fidelity signal conversion, the NRAI01 enables control systems to make precise decisions, enhancing process efficiency and safety in industries like power generation, chemical processing, and oil & gas.

Core advantages and technical highlights

Multi-signal compatibility: The NRAI01’s ability to accept diverse input types—from 4-20 mA transmitters to thermocouples and RTDs—eliminates the need for separate modules. In a chemical plant, it can simultaneously measure reactor temperature (via Type K thermocouple), pressure (4-20 mA), and level (0-10 VDC), streamlining system design and reducing hardware costs by up to 30%.

Exceptional measurement accuracy: With ±0.1% full-scale accuracy for 4-20 mA signals and ±0.2°C for Pt100 RTDs, the NRAI01 delivers reliable data for critical processes. In a pharmaceutical batch reactor, this precision ensures temperature control within ±0.5°C, meeting strict FDA regulations for drug manufacturing. Its low drift (<0.01%/°C) maintains accuracy even as ambient temperatures fluctuate.

Robust noise immunity: Advanced filtering and 2.5 kVAC isolation protect the NRAI01 from electromagnetic interference (EMI) and ground loops. In a steel mill, where large motors generate significant EMI, it continues to accurately measure furnace temperatures, preventing process deviations that could compromise product quality.

Flexible integration: The NRAI01 seamlessly integrates with ABB’s Symphony Plus DCS and third-party controllers via backplane communication. Its compact design (180 mm x 120 mm x 60 mm) fits into space-constrained cabinets, making it ideal for retrofits. In a power plant upgrade, it replaced outdated modules without requiring cabinet modifications, reducing installation time by 50%.

Typical application scenarios

In power generation, the NRAI01 monitors key parameters in steam turbines. It collects data from RTDs measuring bearing temperatures and pressure transmitters in steam lines, feeding real-time values to the DCS. This enables operators to detect anomalies—such as rising bearing temperatures—and adjust cooling water flow before damage occurs, extending turbine lifespan by years.

In chemical processing, the NRAI01 is deployed in distillation columns. It reads 4-20 mA signals from differential pressure transmitters (measuring liquid level) and thermocouples (monitoring column tray temperatures). The module’s fast sampling rate (10 samples/second) captures rapid process changes, allowing the DCS to adjust reflux rates instantly, improving product purity by 2-3%.

In food and beverage production, the NRAI01 ensures pasteurization efficiency. It measures milk temperature via Pt100 RTDs in heating coils, ensuring it reaches 72°C for 15 seconds—critical for eliminating pathogens. The module’s accuracy prevents under-pasteurization (safety risks) or over-pasteurization (quality degradation), reducing waste by 15% in a large dairy facility.

ABB NRAI01

Related model recommendations

NRAO01: Analog output module complementary to the NRAI01, providing 8 channels of 4-20 mA/0-10 VDC outputs. Used together, they form a complete I/O solution for closed-loop control, such as regulating valve positions based on NRAI01’s pressure readings.

NRDI01: Digital input module in the same series, with 16 dry contact inputs. Paired with the NRAI01, it expands system capability to monitor both analog variables and discrete states (e.g., pump run status) in water treatment plants.

PM864: ABB’s DCS controller that processes data from the NRAI01. The PM864 uses NRAI01’s temperature and pressure inputs to execute control algorithms, such as optimizing boiler combustion in power plants.

CI854: PROFIBUS DP communication module that connects the NRAI01 to remote I/O racks. In large-scale refineries, this allows the NRAI01 to collect data from distant sensors and transmit it to the central DCS via Profibus.

TCM100: ABB’s thermocouple transmitter, often paired with the NRAI01 in high-temperature applications. It converts thermocouple signals to 4-20 mA, reducing noise in long cable runs before the NRAI01 processes the signal.

Installation, commissioning and maintenance instructions

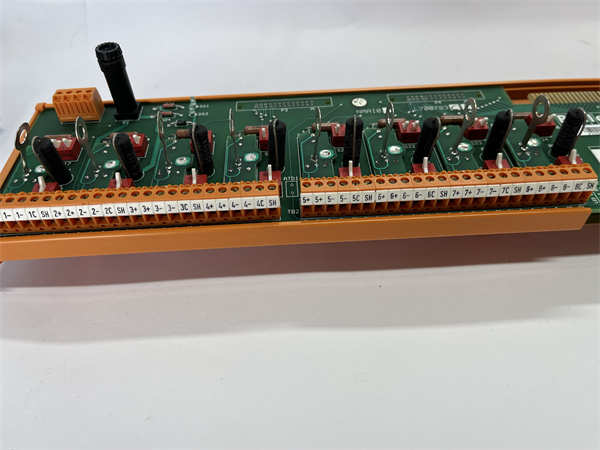

Installation preparation: Mount the NRAI01 on a 35mm DIN rail in a NEMA 4 enclosure, ensuring 30mm clearance for airflow. Use shielded twisted-pair cables for sensor connections, grounding shields at both ends to minimize noise. Verify 24 VDC power supply stability (ripple < 100 mV) and check that input signals match the module’s configured type (e.g., thermocouple vs. 4-20 mA). Avoid installing near high-voltage cables or motor drives to prevent EMI.

Maintenance suggestions: Inspect the NRAI01 quarterly for loose terminals or corrosion, especially in humid environments. Clean conformal coating with a dry cloth to remove dust. Calibrate annually using a precision signal generator (e.g., 4-20 mA calibrator) and ABB’s configuration software to ensure accuracy. If drift exceeds ±0.2% of full scale, replace the module’s internal reference resistor with ABB spare part 3HAC028357-001. For sensor communication errors, check cable continuity and verify sensor compatibility with the NRAI01’s input range.

Service and guarantee commitment

ABB backs the NRAI01 with a 3-year warranty, covering defects in materials and workmanship. During this period, ABB provides free replacement of faulty units and 24/7 technical support via its global helpdesk, with average response times under 2 hours for critical issues.

Customers gain access to online resources—including calibration guides, wiring diagrams, and firmware updates—via ABB’s Customer Portal. Optional on-site services include commissioning assistance and loop verification to ensure optimal performance. ABB guarantees spare parts availability for 15 years post-production, and offers training courses (virtual or in-person) to help technicians maximize the NRAI01’s capabilities. This commitment underscores ABB’s confidence in the module’s durability and its dedication to minimizing customer downtime.