Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | P7LA HNEF105323R0002 |

| Manufacturer | ABB |

| Product category | Safety relay module |

| Number of safety inputs | 2 normally closed (NC) safety contacts |

| Safety outputs | 2 normally open (NO) safety contacts |

| Auxiliary outputs | 1 normally open (NO) auxiliary contact |

| Rated voltage | 24 VDC |

| Rated current | 3 A (safety outputs); 1 A (auxiliary output) |

| Safety category | EN ISO 13849-1: PL e, Cat. 4 |

| Response time | <100 ms |

| Operating temperature | -25°C to +70°C |

| Storage temperature | -40°C to +85°C |

| Humidity tolerance | 5-95% RH (non-condensing) |

| Mounting type | DIN rail (35mm) |

| Dimensions | 22.5mm x 105mm x 75mm |

| Certifications | CE, UL, TÜV |

| Reset function | Manual or automatic reset (configurable) |

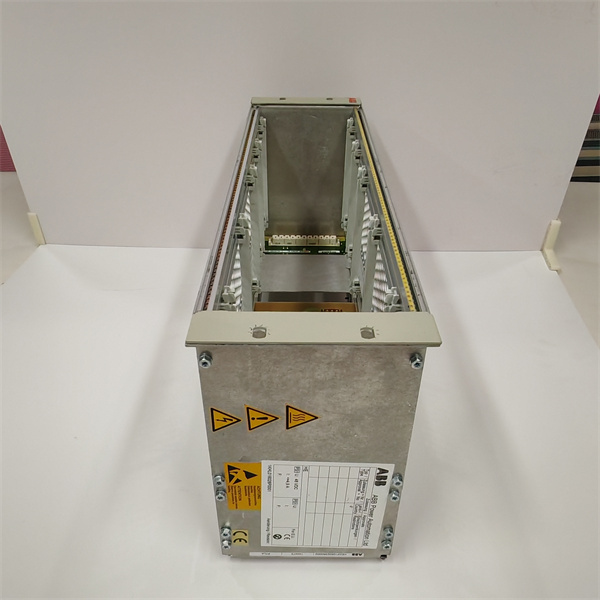

ABB P7LA HNEF105323R0002

Product introduction

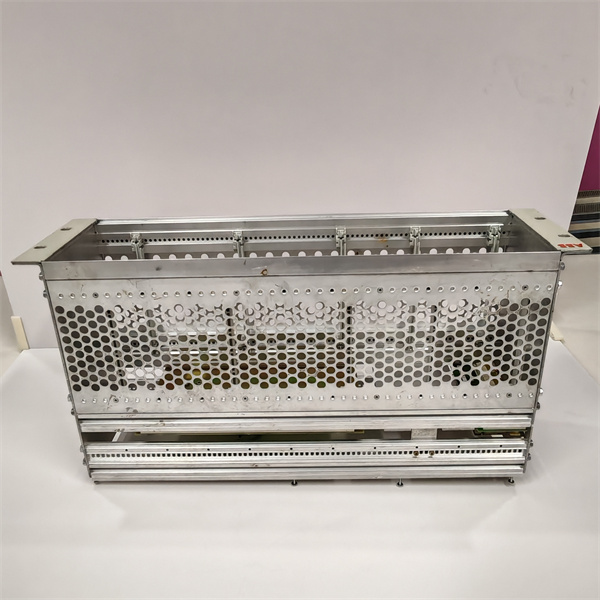

The ABB P7LA HNEF105323R0002 is a high-performance safety relay module designed to monitor and control safety-related functions in industrial automation systems. As a critical component in machine safety circuits, it ensures that hazardous machinery or processes are promptly shut down when a safety hazard is detected, protecting workers and equipment from potential harm.

Equipped with 2 safety inputs and 2 safety outputs, the ABB P7LA HNEF105323R0002 is engineered to meet the strict requirements of EN ISO 13849-1 (PL e, Cat. 4), making it suitable for high-risk applications where safety is paramount. Its compact design and easy integration into existing control systems allow for seamless implementation in various industrial environments, from manufacturing plants to material handling facilities. By providing reliable monitoring of emergency stops, safety gates, and light curtains, the ABB P7LA HNEF105323R0002 plays a vital role in maintaining a safe working environment.

Core advantages and technical highlights

High safety integrity: The ABB P7LA HNEF105323R0002 achieves EN ISO 13849-1 PL e (Performance Level e) and Cat. 4, representing one of the highest safety ratings for industrial safety devices. This ensures that it can reliably detect faults in safety circuits and respond appropriately, minimizing the risk of hazardous situations. In applications such as robotic workcells or press machines, where even a momentary failure could lead to serious injury, this high safety integrity is indispensable.

Fast response time: With a response time of less than 100 ms, the ABB P7LA HNEF105323R0002 can quickly shut down hazardous processes when a safety input is triggered. For example, when an emergency stop button is pressed or a safety gate is opened, the relay module immediately de-energizes the safety outputs, stopping the machinery before an accident occurs. This rapid response is crucial in high-speed manufacturing environments where every millisecond counts.

Flexible reset options: The ABB P7LA HNEF105323R0002 offers both manual and automatic reset functions, which can be configured based on specific application requirements. Manual reset is ideal for situations where a worker must visually inspect the area before restarting the machinery, ensuring that all hazards have been addressed. Automatic reset, on the other hand, is suitable for applications where frequent stops and starts are necessary, such as in conveyor systems, reducing downtime and improving productivity.

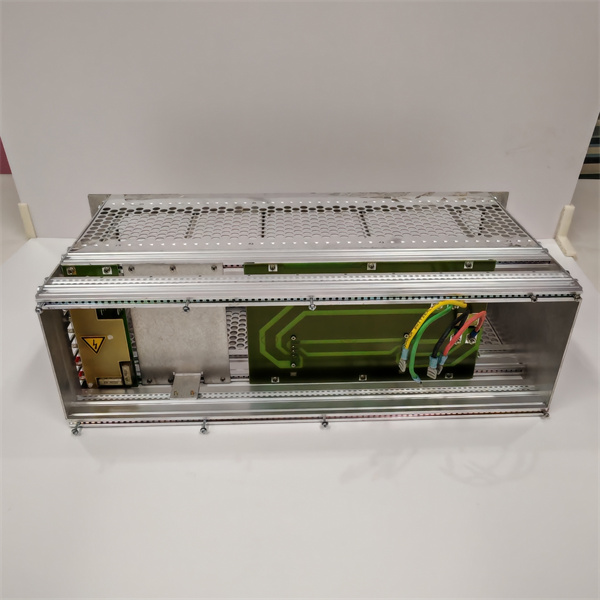

Compact and easy to install: Measuring just 22.5mm in width, the ABB P7LA HNEF105323R0002 occupies minimal space on the DIN rail, making it suitable for crowded control cabinets. Its plug-in terminals simplify wiring, reducing installation time and the risk of wiring errors. The module also features clear status indicators (LEDs) that provide visual feedback on the operating state, making troubleshooting and maintenance easier.

Typical application scenarios

In automotive manufacturing plants, the ABB P7LA HNEF105323R0002 is used to monitor safety gates around robotic welding stations. When a safety gate is opened, the relay module detects the input signal and immediately shuts down the robot and welding equipment, preventing access to the hazardous area while the robot is in operation. The manual reset function ensures that the robot can only be restarted after the gate is closed and a worker has confirmed that the area is safe.

Within packaging machinery, the ABB P7LA HNEF105323R0002 monitors emergency stop buttons and light curtains. If a worker reaches into the machine’s operating area and breaks the light curtain, the relay module triggers an immediate shutdown of the conveyor and packaging mechanisms. The fast response time prevents the worker from coming into contact with moving parts, reducing the risk of injury.

In material handling facilities, the ABB P7LA HNEF105323R0002 is integrated into the safety circuit of overhead cranes. It monitors limit switches that detect overtravel of the crane’s hoist or trolley. When an overtravel condition is detected, the relay module shuts down the crane’s motor, preventing collisions with structures or other equipment. The automatic reset function allows the crane to resume operation once the overtravel condition is cleared, minimizing downtime.

ABB P7LA HNEF105323R0002

Related model recommendations

ABB P7LA HNEF105324R0002: A variant of the ABB P7LA HNEF105323R0002 with 3 safety inputs, suitable for applications requiring monitoring of additional safety devices, such as multiple emergency stop buttons.

ABB P7ZA HNEF105325R0002: A safety relay module with a built-in timer function, which can be used in conjunction with the ABB P7LA HNEF105323R0002 in applications where a time delay is needed before restarting the machinery.

ABB MS132: A manual motor starter that pairs with the ABB P7LA HNEF105323R0002 to provide motor protection and safety shutdown capabilities.

ABB S200 miniature circuit breaker: Protects the ABB P7LA HNEF105323R0002 and the safety circuit from overcurrent conditions, ensuring reliable operation.

ABB CLMD132: A contactor that is controlled by the ABB P7LA HNEF105323R0002 to switch the power supply to the hazardous machinery, providing a high-current switching capability.

ABB 2TLA010029R0000: An emergency stop button that connects to the ABB P7LA HNEF105323R0002, serving as a manual safety input device.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB P7LA HNEF105323R0002, ensure that the 35mm DIN rail is securely mounted in a clean, dry control cabinet. Verify that the ambient temperature is within -25°C to +70°C and the humidity is 5-95% non-condensing. Gather the necessary tools: a screwdriver for mounting the module and wiring, and wire strippers for preparing the connecting wires. Check that the 24 VDC power supply is stable and properly fused.

Commissioning steps: After installing the ABB P7LA HNEF105323R0002, connect the safety inputs (e.g., emergency stop buttons, safety gates) to the NC input terminals and the safety outputs to the machinery’s control circuit. Configure the reset function (manual or automatic) using the DIP switches on the module. Power on the module and check the status LEDs to ensure that the module is operating correctly. Test the safety circuit by triggering each safety input (e.g., pressing the emergency stop button) and verifying that the safety outputs de-energize and the machinery shuts down as expected.

Maintenance suggestions: Inspect the ABB P7LA HNEF105323R0002 quarterly for signs of physical damage, loose connections, or corrosion. Clean the module’s surface with a dry cloth if necessary. Test the safety circuit monthly by triggering each safety input to ensure that the relay module responds correctly. Check the status LEDs regularly to ensure that they are functioning properly. If a fault is detected, first check the wiring and the connected safety devices before replacing the module. When replacing the module, ensure that the power is disconnected and that the new module is configured with the same settings as the old one.

Service and guarantee commitment

The ABB P7LA HNEF105323R0002 comes with a 24-month warranty from the date of purchase, covering manufacturing defects and ensuring compliance with the published safety standards. If a fault is confirmed within this period, ABB will replace the module free of charge.

ABB provides comprehensive technical support for the ABB P7LA HNEF105323R0002, including access to installation manuals, user guides, and safety certification documents via its online portal. Technical experts are available via phone and email to assist with installation, configuration, and troubleshooting. For customers requiring additional support, ABB offers optional on-site training and service contracts, ensuring that the safety relay module is installed and maintained correctly to provide reliable protection.