Description

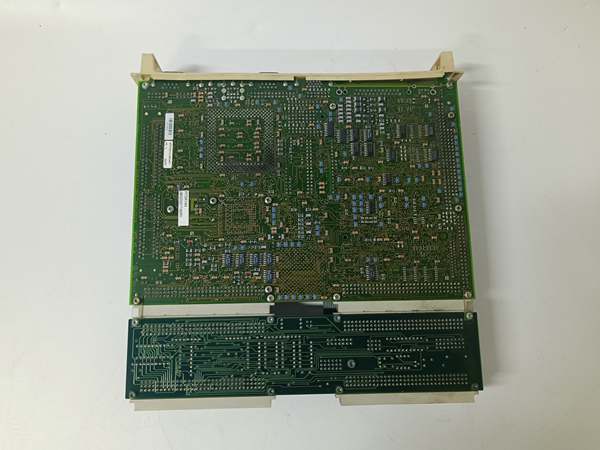

PFSK164 3BSE021180R1: Product Overview

This module operates within the communication layer of ABB 800xA distributed control systems (DCS) and S800 I/O architectures, serving as a fieldbus interface between the DCS controller and PROFIBUS-enabled field devices (e.g., sensors, actuators, drives). Its role is to translate controller commands into PROFIBUS protocol frames, convert field device data (process variables, diagnostics) into DCS-interpretable formats, and manage real-time data exchange. In a typical system, it mounts on an S800 I/O carrier, drawing power from the DCS backplane and synchronizing with the control network for seamless integration.

Core functionality includes supporting both PROFIBUS DP (high-speed device communication, 9.6 kbps–12 Mbps) and PA (intrinsically safe process instrumentation, 31.25 kbps), processing up to 8 concurrent field device connections, and providing 2.5kV RMS galvanic isolation between the DCS backplane and field circuits to mitigate ground loop interference. It handles device diagnostics (e.g., wire breaks, configuration errors, HART data) and integrates with ABB’s Asset Management tools for remote monitoring of field device health.

The module belongs to the ABB S800 I/O Series, a platform optimized for modular I/O expansion and mixed-protocol integration. Benefits of this series include hot-swappable components for minimal downtime, compatibility with ABB Engineering Base software for configuration, and adherence to IEC 61158 standards for interoperability. This series streamlines system upgrades by allowing incremental addition of fieldbus modules without reconfiguring the entire DCS, preserving engineering investment in existing infrastructure.

ABB PFSK164 3BSE021180R1

PFSK164 3BSE021180R1: Technical Specifications

-

Model Number: PFSK164 3BSE021180R1

-

Manufacturer: ABB Ltd.

-

Product Type: Fieldbus Communication Module

-

Supported Protocols: PROFIBUS DP V1, PROFIBUS PA (intrinsically safe option)

-

Data Rate: 9.6 kbps–12 Mbps (DP); 31.25 kbps (PA)

-

Number of Channels: 8 (isolated fieldbus connections)

-

Isolation Voltage: 2.5kV RMS (channel-to-backplane, channel-to-channel)

-

Node Capacity: Up to 126 nodes (DP); up to 32 nodes (PA, with segment couplers)

-

Power Supply: 24V DC (from S800 carrier, 1.5W max)

-

Operating Temperature: -25°C to +60°C

-

Storage Temperature: -40°C to +85°C

-

Protection Rating: IP20 (enclosure)

-

Dimensions: 110mm (H) x 35mm (W) x 120mm (D)

-

Weight: ~0.3kg

-

Certifications: CE, UL (cULus Listed), RoHS, ATEX Zone 2 (PA variant)

Core Features & Customer Value

Support for both PROFIBUS DP and PA protocols allows integration of diverse field devices—from high-speed drives (DP) to hazardous-area sensors (PA)—within a single module. For engineers, this eliminates the need for separate protocol converters, simplifying system architecture and reducing wiring complexity. The 12 Mbps DP data rate ensures real-time control for applications like robotic axis synchronization, where millisecond delays can impact precision.

Galvanic isolation (2.5kV RMS) protects the DCS backplane from voltage transients generated by inductive loads (e.g., motor starters), minimizing controller damage risk. Channel-level diagnostics (via ABB 800xA System Alarm Manager) flag issues like “node 5 offline” or “PA segment fault,” enabling proactive maintenance instead of reactive troubleshooting. The hot-swappable design permits module replacement during operation, critical for 24/7 facilities like power plants where downtime costs are high.

Compact dimensions (35mm width) maximize I/O density on S800 carriers, supporting up to 16 modules per rack. This scalability reduces cabinet space in brownfield expansions, where panel real estate is often constrained. Compatibility with ABB’s legacy DCS platforms (e.g., INFI-90) via gateway modules facilitates phased migration without full system replacement, preserving capital investment in existing infrastructure.

ABB PFSK164 3BSE021180R1

Typical Applications

In a chemical plant, the module connects PROFIBUS PA pH sensors and pressure transmitters in the reactor area to an ABB 800xA DCS. The intrinsically safe PA variant ensures compliance with Zone 1/2 hazardous area requirements, while diagnostics monitor sensor calibration status remotely.

At an automotive assembly line, it interfaces PROFIBUS DP servo drives (controlling robotic welders) with an ABB AC500 PLC. The 12 Mbps rate supports synchronized motion control, ensuring consistent weld seam placement across vehicle models.

In a water treatment facility, the module links PROFIBUS DP variable frequency drives (pump speed control) to the SCADA system. The isolation feature protects against transients from pump startups, maintaining stable communication for flow regulation.