Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | PM510V08 3BSE00B373R1 |

| Manufacturer | ABB |

| Product category | Programmable Logic Controller (PLC) module |

| Rated voltage | 24 V DC ±15% |

| Power consumption | ≤12 W |

| Processing capacity | 32-bit RISC processor, 80 MHz |

| Memory | 256 KB RAM, 2 MB flash (program storage) |

| Number of I/O points | Up to 512 (expandable via remote modules) |

| Built-in I/O | 8 digital inputs (24 V DC), 8 digital outputs (relay) |

| Communication interfaces | Ethernet (Modbus TCP), RS485 (Modbus RTU), Profibus DP |

| Programming language | IEC 61131-3 (LD, FBD, ST, IL, SCL) |

| Operating temperature | 0°C to 60°C |

| Dimensions | 120 mm × 100 mm × 80 mm |

| Mounting type | DIN rail mount (35 mm) |

| Protection rating | IP20 |

| Certifications | IEC 61131-2, CE, UL, RoHS |

| Cycle time | ≤10 ms (for 500 logic instructions) |

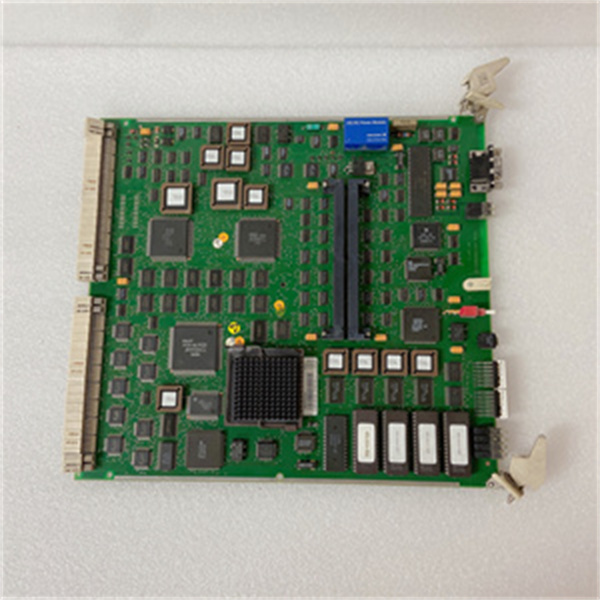

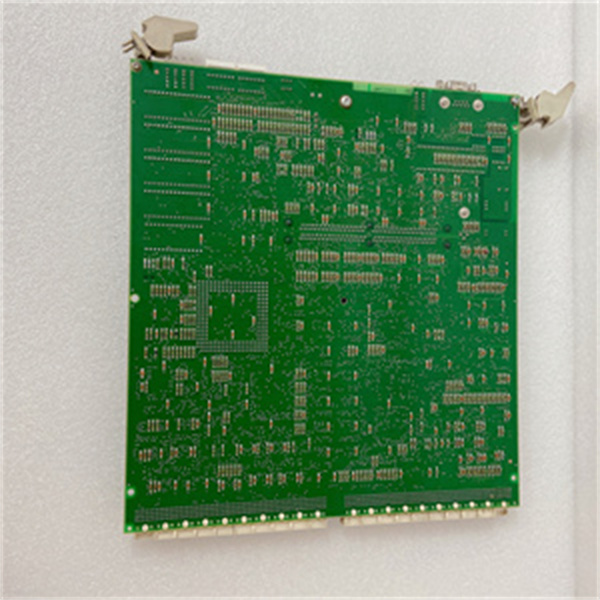

ABB PM510V08 3BSE00B373R1

Product introduction

The PM510V08 3BSE00B373R1 is a compact programmable logic controller (PLC) module from ABB, positioned as a smaller-scale variant of the PM510V16 in the AC500 series. Designed for lightweight industrial automation systems, this PLC targets applications with modest I/O requirements—such as small machinery, standalone equipment, and decentralized control nodes in larger networks.

While sharing the same processing core as the PM510V16, the PM510V08 features half the number of built-in I/O points, making it a cost-effective choice for systems that don’t require 16 inputs and outputs. Its compact size and lower power consumption make it ideal for installation in space-constrained enclosures, such as those in laboratory equipment, small packaging machines, or auxiliary control panels. Like its larger counterpart, it supports expandability via remote modules, ensuring it can grow with evolving system needs.

Core advantages and technical highlights

Compact design for space-constrained applications

With dimensions of 120 mm × 100 mm × 80 mm (20 mm narrower than the PM510V16), the PM510V08 fits easily into small control cabinets—critical for equipment like benchtop medical devices or portable industrial tools. Its reduced footprint allows integration into machinery where cabinet space is limited, such as a desktop 3D scanner with built-in automation features.

Right-sized I/O for small systems

The 8 built-in digital inputs and 8 relay outputs are perfectly matched to applications like coffee vending machines (monitoring 5 sensors and controlling 6 actuators) or small water pumps (managing 4 float switches and 3 valves). This avoids over-provisioning I/O, reducing costs compared to using the PM510V16 in low-complexity setups.

Energy-efficient operation

With a power consumption of ≤12 W (3 W less than the PM510V16), the module is suitable for battery-backed systems or remote installations with limited power. In solar-powered weather stations, for example, its lower energy use extends battery life, reducing maintenance intervals.

Seamless expandability

While the built-in I/O is limited to 8 points, the PM510V08 can connect to remote modules (including the DSAI130A digital input module) via Profibus DP, expanding to 512 I/O points. This scalability allows it to transition from a standalone controller in a small conveyor to a node in a factory-wide automation network as production scales.

Key differences from PM510V16 3BSE008358R1

| Feature | PM510V16 | PM510V08 |

| Built-in I/O | 16 inputs, 16 outputs | 8 inputs, 8 outputs |

| Max expandable I/O | 1024 points | 512 points |

| Dimensions | 140 mm × 100 mm × 80 mm | 120 mm × 100 mm × 80 mm |

| Power consumption | ≤15 W | ≤12 W |

| Cycle time | ≤10 ms (1000 instructions) | ≤10 ms (500 instructions) |

| Ideal application scale | Medium systems (50+ I/O) | Small systems (≤50 I/O) |

ABB PM510V08 3BSE00B373R1

Typical application scenarios

Small-scale packaging equipment

A tabletop candy wrapping machine uses the PM510V08 to control 6 servo motors (outputs) and monitor 5 photoelectric sensors (inputs) that detect candy position. Its compact size fits into the machine’s control box, while Modbus RTU communication links to a weight scale for quality checks.

Laboratory automation

In a chemical analysis lab, the PLC manages 4 reagent pumps (outputs) and 7 temperature/level sensors (inputs) for a sample preparation station. The 8 built-in I/O points handle core operations, with a DSAI130A module adding 8 extra inputs for specialized detectors. Ethernet connectivity allows researchers to log data to a central server.

Building auxiliary systems

A commercial office’s ventilation sub-system uses the PM510V08 to control 6 dampers (outputs) and monitor 5 CO₂ sensors (inputs). Its low power consumption suits installation in ceiling-mounted enclosures, and Profibus DP connects to a main BMS controller for centralized management.

Related model recommendations

ABB DSAI130A 3BSE018292R1

Expands the PM510V08’s input capacity by 16 points, ideal for adding sensors to small machinery without exceeding the PLC’s 512 I/O limit.

ABB AC500-eCo AI831 analog input module

Adds temperature and pressure monitoring capabilities, useful for upgrading the PLC to control environmental chambers or small boilers.

ABB CP430 HMI panel

A 3.5-inch touchscreen that connects via Ethernet, providing a compact operator interface for machines using the PM510V08.

ABB CI854A Profibus adapter

Extends the PLC’s Profibus network, enabling connection to remote I/O in scattered locations (e.g., different floors of a building).

ABB TB857 surge protector

Safeguards the PM510V08 and connected sensors from voltage spikes in industrial or commercial power grids.

Installation, commissioning and maintenance instructions

Installation: Mount on a 35 mm DIN rail with 25 mm clearance for cooling. Connect 24 V DC power (protected by a 1.5 A fuse) using 0.5 – 1.5 mm² cable. Wire sensors to inputs 1-8 and actuators to outputs 1-8, using shielded cable grounded at the PLC end. For remote I/O, connect Profibus DP cable to the communication port.

Commissioning: Program using ABB Automation Builder, leveraging IEC 61131-3 languages. Configure communication protocols (Ethernet IP, Modbus baud rate) to match system requirements. Test I/O by simulating sensor signals and verifying output activation. Optimize code to ensure cycle times stay below 10 ms for critical logic.

Maintenance: Inspect quarterly for dust and loose connections. Backup the program monthly to a secure storage device. Monitor CPU load via HMI—if exceeding 80% regularly, simplify logic or add remote I/O to offload processing. Check power supply voltage to maintain 24 V DC ±15%. Replace the module if communication fails or outputs become unresponsive, ensuring program compatibility with the replacement unit.

Service and guarantee commitment

The PM510V08 3BSE00B373R1 includes a 5-year warranty covering manufacturing defects and compliance with IEC 61131-2 standards. ABB’s technical support offers programming guidance and troubleshooting via phone/email, with 24-hour response for urgent issues.

Extended services include on-site setup, operator training, and software updates. ABB guarantees compatibility with AC500 series expansion modules and future firmware releases, ensuring the PLC remains a reliable control solution for small-scale automation systems.