Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | PM510V16 3BSE008358R1 |

| Manufacturer | ABB |

| Product category | Programmable Logic Controller (PLC) module |

| Rated voltage | 24 V DC ±15% |

| Power consumption | ≤15 W |

| Processing capacity | 32-bit RISC processor, 80 MHz |

| Memory | 256 KB RAM, 2 MB flash (program storage) |

| Number of I/O points | Up to 1024 (expandable via remote modules) |

| Built-in I/O | 16 digital inputs (24 V DC), 16 digital outputs (relay) |

| Communication interfaces | Ethernet (Modbus TCP), RS485 (Modbus RTU), Profibus DP |

| Programming language | IEC 61131-3 (LD, FBD, ST, IL, SCL) |

| Operating temperature | 0°C to 60°C |

| Dimensions | 140 mm × 100 mm × 80 mm |

| Mounting type | DIN rail mount (35 mm) |

| Protection rating | IP20 |

| Certifications | IEC 61131-2, CE, UL, RoHS |

| Cycle time | ≤10 ms (for 1000 logic instructions) |

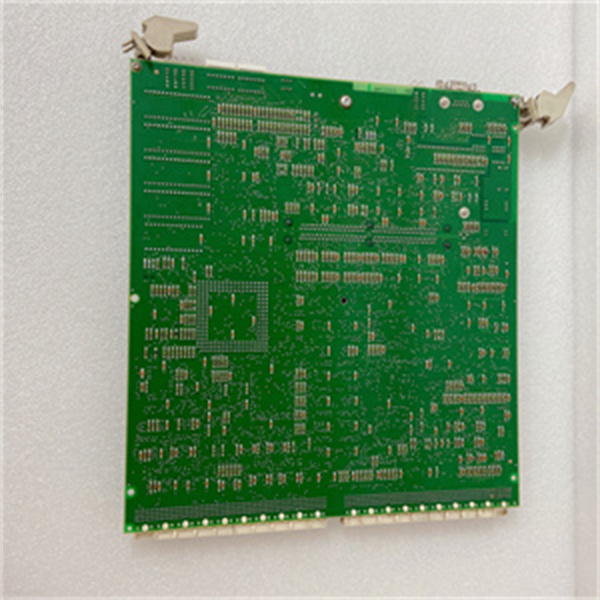

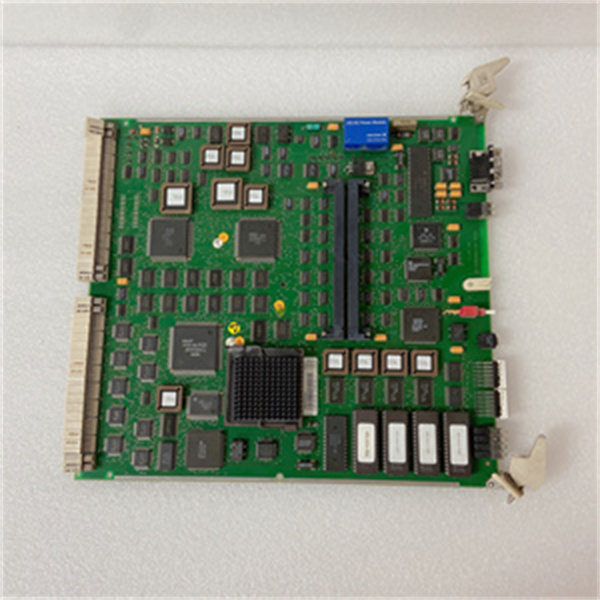

ABB PM510V16 3BSE008358R1

Product introduction

The PM510V16 3BSE008358R1 is a compact yet powerful programmable logic controller (PLC) module from ABB, designed to serve as the core of small to medium-scale industrial automation systems. As part of ABB’s AC500 series, this PLC integrates processing capabilities with built-in I/O, making it a standalone solution for applications requiring localized control—such as machine automation, material handling systems, and small-scale process lines.

Unlike the DSAI130A, which functions solely as a digital input module, the PM510V16 combines signal acquisition, logic execution, and output control in a single device. Its 16 built-in digital inputs and 16 relay outputs eliminate the need for separate I/O modules in simple systems, while expandability via remote I/O (up to 1024 points) allows scaling for more complex setups. With multi-protocol communication and support for standard programming languages, it offers flexibility for integration with existing equipment and future upgrades.

Core advantages and technical highlights

All-in-one design with expandability

The PM510V16’s built-in 16 inputs and 16 outputs simplify installation in small systems, such as a packaging machine with 10 sensors and 8 actuators. For larger applications—like a conveyor network with 50+ I/O points—it seamlessly connects to remote modules (including the DSAI130A) via Profibus DP, avoiding the need for a separate controller. This scalability makes it ideal for both standalone machines and integrated production lines.

Multi-protocol communication

Equipped with Ethernet (Modbus TCP), RS485 (Modbus RTU), and Profibus DP, the PLC communicates with a wide range of devices—from HMI panels (via Ethernet) to variable frequency drives (via Modbus RTU) and remote I/O modules (via Profibus DP). In a food processing line, for example, it can collect data from DSAI130A input modules monitoring temperature sensors, send commands to motor drives via Modbus, and display real-time status on an HMI via Ethernet.

Efficient processing with standard programming

The 80 MHz 32-bit RISC processor executes up to 1000 logic instructions in ≤10 ms, ensuring responsive control in time-critical applications like automated assembly. Support for IEC 61131-3 languages allows programmers to use familiar tools—ladder diagram (LD) for simple relay logic, structured text (ST) for complex algorithms—reducing development time. In a water treatment skid, this enables quick implementation of PID-based pump control alongside safety interlocks.

Reliable operation in industrial environments

Built to withstand the rigors of factory floors, the PM510V16 operates in the same 0°C to 60°C range as the DSAI130A, with immunity to EMI and electrical noise. Its relay outputs (rated 250 V AC/30 V DC, 5 A) directly control small motors and valves, eliminating the need for intermediate contactors in low-power applications. In a workshop with frequent power fluctuations, its 24 V DC ±15% voltage tolerance ensures stable operation without resetting.

Key differences from DSAI130A 3BSE018292R1

| Feature | DSAI130A | PM510V16 |

| Primary function | Digital input acquisition | Complete control system (I/O + processing) |

| Core component | Input circuitry with isolation | 32-bit processor + built-in I/O |

| I/O capability | 16 inputs (no outputs) | 16 inputs + 16 outputs (expandable to 1024) |

| Programming | None (passive signal transmission) | IEC 61131-3 languages |

| Communication | Profibus DP (slave only) | Ethernet, RS485, Profibus DP (master/slave) |

| Power consumption | ≤2 W | ≤15 W |

ABB DSAI130A 3BSE018292R1

Typical application scenarios

Machine automation

In a desktop 3D printer production line, the PM510V16 controls 12 conveyor belts, 8 robotic pickers, and 10 quality sensors. Its built-in I/O handles basic operations, while a DSAI130A module connected via Profibus DP adds 16 extra inputs for fine-grained sensor data (e.g., print bed temperature). The PLC executes logic to synchronize belt speeds with picker movements, ensuring efficient assembly.

Water treatment skids

A small-scale water filtration system uses the PM510V16 to control 4 pumps, 6 valves, and 8 pressure sensors. Its relay outputs directly switch pump motors, while inputs monitor flow switches. The PLC runs PID algorithms to maintain constant pressure, with Modbus TCP communication sending data to a SCADA system for remote monitoring.

Warehouse material handling

In a automated storage and retrieval system (AS/RS) for small parts, the PM510V16 manages 10 stacker cranes and 20 barcode scanners. It connects to DSAI130A modules via Profibus DP to expand input capacity, tracking crane positions and part locations. Ethernet communication links to a warehouse management system, enabling order-driven automation.

Related model recommendations

ABB DSAI130A 3BSE018292R1

A remote digital input module that expands the PM510V16’s input capacity, ideal for systems requiring more than 16 inputs (e.g., large sensor networks).

ABB AC500-eCo CPU expansion modules

Analog I/O modules (e.g., AI831, AO821) that add temperature, pressure, and flow control capabilities to the PM510V16, suitable for process automation.

ABB CP635 HMI panel

A 5.7-inch touchscreen interface that connects to the PM510V16 via Ethernet, allowing operators to monitor status and adjust setpoints.

ABB CI854A Profibus adapter

Extends the PM510V16’s Profibus DP network distance, enabling connection to DSAI130A modules in remote parts of a facility (e.g., warehouse corners).

ABB TB857 surge protector

Protects the PLC and connected DSAI130A modules from voltage spikes, critical in industrial environments with frequent motor starts.

Installation, commissioning and maintenance instructions

Installation: Mount the PM510V16 on a 35 mm DIN rail, leaving 30 mm clearance for cooling. Connect 24 V DC power (protected by a 2 A fuse) to the terminal block. Wire sensors to built-in digital inputs (1-16) and actuators to relay outputs (1-16) using 0.5 – 1.5 mm² cable. For remote I/O (e.g., DSAI130A), connect Profibus DP cable to the PLC’s communication port. Use shielded cable for all connections, grounding shields at the PLC end.

Commissioning: Program the PLC using ABB’s Automation Builder software, implementing logic via IEC 61131-3 languages. Configure communication protocols (e.g., set Ethernet IP address, Profibus baud rate). Test I/O by forcing outputs and verifying input detection. Calibrate cycle times if needed—optimize code to ensure response within 10 ms for critical functions.

Maintenance: Inspect quarterly for loose connections and dust (clean with compressed air). Backup the program to a USB drive or network server monthly. Check power supply voltage to ensure it stays within 24 V DC ±15%. Monitor CPU load via HMI—if consistently above 80%, optimize logic or upgrade to a higher-performance PLC. Replace the module if it fails to communicate or execute logic, ensuring program compatibility with the replacement unit.

Service and guarantee commitment

The PM510V16 3BSE008358R1 comes with a 5-year warranty, covering manufacturing defects and ensuring compliance with IEC 61131-2 standards. ABB’s technical support provides programming assistance, firmware updates, and troubleshooting via phone or email, with 24-hour response for critical issues.

Extended service includes on-site commissioning, operator training, and software version management. ABB guarantees compatibility with all AC500 series expansion modules (including the DSAI130A) and future software updates, ensuring the PLC remains a viable control core for evolving automation systems. This commitment reinforces its role as a reliable, long-term solution for industrial control.