Description

Detailed parameter table

| Parameter name | Parameter value |

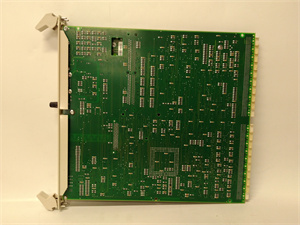

| Product model | PM511V16 3BSE011181R1 |

| Manufacturer | ABB |

| Product category | Programmable Logic Controller (PLC) module |

| Operating voltage | 24 V DC ±10% |

| Processing capacity | 100 k steps program memory; 8 MB data memory |

| I/O capacity | Up to 1024 digital points; 256 analog points (with expansion modules) |

| Communication protocols | Modbus RTU, Ethernet/IP, PROFIBUS DP |

| Operating temperature range | 0°C to +60°C (32°F to +140°F) |

| Dimensions (LxWxH) | 120 mm x 80 mm x 110 mm (4.72 in x 3.15 in x 4.33 in) |

| Protection rating | IP20 |

| Programming languages | IEC 61131-3 (LD, FBD, ST, SCL, IL) |

| Installation type | DIN rail mounting (35 mm) |

| Certification | CE, UL, cUL, ATEX, IECEx |

PM511V16

Product introduction

The ABB PM511V16 3BSE011181R1 is a compact yet powerful programmable logic controller module, part of ABB’s AC500 series—a family renowned for reliability in mid-sized industrial automation applications. This controller combines efficient processing capabilities with flexible connectivity to handle diverse control tasks in manufacturing and process industries.

ABB PM511V16 3BSE011181R1 serves as the core of distributed control systems, executing logic operations, managing I/O signals, and facilitating data exchange between field devices and upper-level monitoring systems. Its compact design makes it ideal for applications where space is limited, while its expandable architecture allows system scalability as operational needs grow. Whether controlling production lines, material handling systems, or environmental equipment, ABB PM511V16 3BSE011181R1 delivers consistent performance to ensure operational efficiency and process stability.

Core advantages and technical highlights

Balanced performance: ABB PM511V16 3BSE011181R1 features a 32-bit processor that executes 10,000 instructions per millisecond, striking an optimal balance between speed and energy efficiency. This ensures responsive control of time-critical processes without unnecessary power consumption, making it suitable for both continuous and batch operations.

Flexible expansion: Unlike fixed I/O controllers, ABB PM511V16 3BSE011181R1 supports up to 16 expansion modules via its backplane bus, allowing customization with digital, analog, or specialty I/O (e.g., temperature, motion) based on application requirements. This modularity reduces upfront investment by enabling phased system development.

Seamless integration: Equipped with multiple communication ports, ABB PM511V16 3BSE011181R1 easily connects to HMIs, SCADA systems, and enterprise software. Its compatibility with industry-standard protocols ensures interoperability with third-party devices, simplifying retrofits in mixed-vendor environments.

User-centric design: ABB PM511V16 3BSE011181R1 is programmed using ABB’s Automation Builder software, which offers a unified environment for configuration, testing, and troubleshooting. The controller’s front-facing USB port allows quick program transfers and firmware updates, while its status LEDs provide at-a-glance diagnostics for rapid issue identification.

Typical application scenarios

In food and beverage processing, ABB PM511V16 3BSE011181R1 excels at controlling filling lines and packaging machinery. Its precise timing capabilities ensure accurate portioning and sealing, while its resistance to temperature fluctuations (0°C to +60°C) allows installation in cold storage areas or near heat-generating equipment. Integration with weighing sensors and vision systems via analog and digital I/O enables quality checks during production, reducing waste.

Within water treatment plants, ABB PM511V16 3BSE011181R1 manages pump stations, filtration systems, and chemical dosing processes. Its ability to handle multiple analog signals (e.g., pH, turbidity, flow rate) allows closed-loop control of water quality parameters, ensuring compliance with regulatory standards. The controller’s communication features enable remote monitoring of plant operations, minimizing on-site staffing requirements.

In automotive component manufacturing, ABB PM511V16 3BSE011181R1 coordinates assembly line robots, conveyor systems, and inspection stations. Its fast processing speed ensures synchronized movement of parts between workstations, while its expandable I/O accommodates the diverse sensors and actuators used in quality control—from pressure transducers to laser scanners.

PM511V16

Related model recommendations

ABB PM513V16 3BSE011182R1: A higher-performance variant of ABB PM511V16 3BSE011181R1 with increased memory and faster processing, suitable for more complex control tasks.

ABB DI521 3BSE008549R1: Digital input module compatible with ABB PM511V16 3BSE011181R1, adding 16 digital input points for connecting sensors and switches.

ABB AO523 3BSE008553R1: Analog output module that extends ABB PM511V16 3BSE011181R1 with 4 channels for controlling valves, variable speed drives, and other analog actuators.

ABB CM578 3BSE013234R1: Ethernet communication module that enhances ABB PM511V16 3BSE011181R1‘s network capabilities with gigabit connectivity and advanced security features.

ABB PM501 3BSE008509R1: Entry-level controller in the AC500 series, offering a cost-effective alternative to ABB PM511V16 3BSE011181R1 for small-scale applications with basic I/O needs.

ABB AC500-eCo PM564-R-ETH: Compact controller with similar footprint to ABB PM511V16 3BSE011181R1 but optimized for energy management applications.

ABB Automation Builder: Software suite specifically designed for programming and configuring ABB PM511V16 3BSE011181R1, featuring simulation tools and library of pre-built function blocks.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing ABB PM511V16 3BSE011181R1, ensure the DIN rail is securely mounted in a dust-free enclosure with ambient temperature between 0°C and 60°C. Required tools include a Phillips screwdriver, wire strippers, and torque wrench (set to 0.5–0.6 Nm for terminal connections). Use twisted-pair cables for analog signals to minimize noise interference. Verify that the 24 V DC power supply is properly grounded and protected by a 2A circuit breaker. Allow at least 20 mm of clearance above and below the module for ventilation.

Maintenance suggestions: For ABB PM511V16 3BSE011181R1, perform monthly visual inspections to check for loose connections or signs of overheating (discoloration of terminals). Back up the program to a secure storage device quarterly using Automation Builder software. Clean dust from ventilation slots annually with compressed air (max 5 bar) to prevent overheating. If communication errors occur, check Ethernet cable integrity and verify IP address settings via the controller’s HMI or software. When replacing expansion modules, power down ABB PM511V16 3BSE011181R1 to avoid damaging the backplane bus. Update firmware annually using the latest version from ABB’s website to ensure compatibility with new expansion modules.

Service and guarantee commitment

ABB PM511V16 3BSE011181R1 comes with a 3-year warranty from the date of purchase, covering manufacturing defects and performance issues under normal operating conditions. ABB’s technical support team provides 24/7 assistance via phone and email, with response times guaranteed within 8 hours for standard inquiries.

We offer on-site commissioning services for ABB PM511V16 3BSE011181R1, including program development, I/O testing, and network integration, performed by certified automation engineers. Extended warranty options up to 5 years are available, including annual preventive maintenance checks. In case of hardware failure, ABB guarantees a 3-day repair turnaround at regional service centers, with loaner units available for critical applications to minimize downtime. All replacement parts used in servicing ABB PM511V16 3BSE011181R1 are genuine ABB components, ensuring consistent performance and reliability.