Description

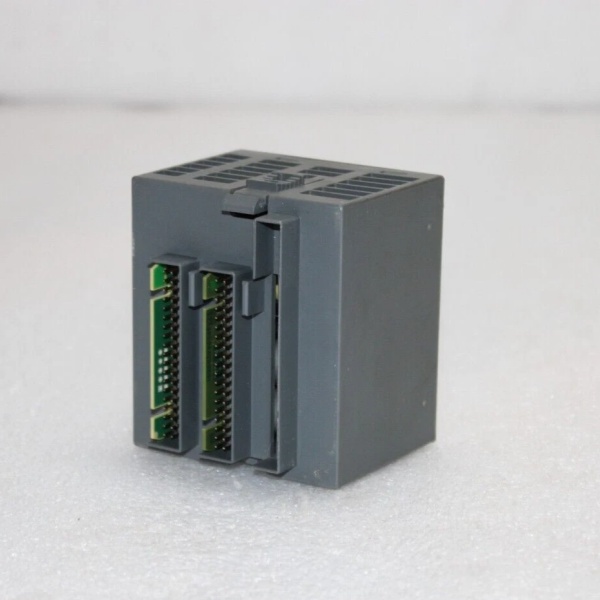

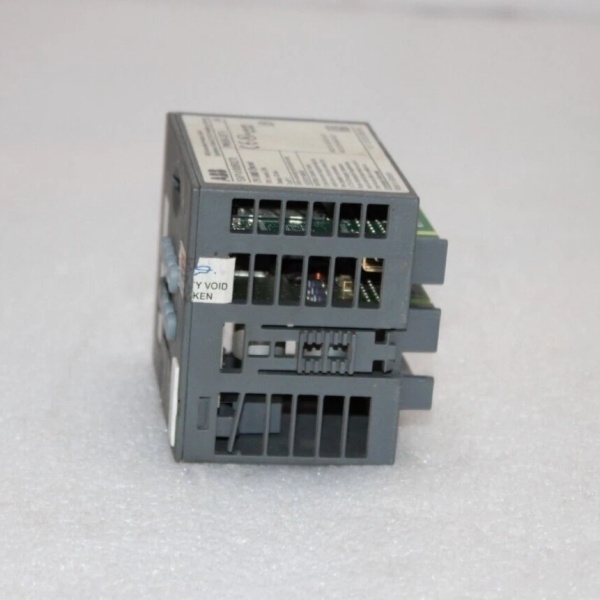

ABB PM5650-2ETH 1SAP141000R0278

-

Model Number: PM5650-2ETH 1SAP141000R0278 -

Manufacturer: ABB -

Product Type: PLC CPU Module -

Processor: 32-bit PowerPC 405, 266 MHz -

Memory: 512MB RAM, 1GB Flash (user program/log storage) -

Ethernet Ports: 2x 10/100Mbps RJ45 (supports redundancy, daisy-chaining) -

Communication Protocols: Modbus TCP, Ethernet IP, PROFINET (slave), HTTP/FTP (web server) -

Programming Environment: CODESYS V3 (IEC 61131-3 compliant) -

I/O Capacity: Up to 512 I/O points (via AC500 I/O modules, local/remote) -

Operating Temperature: -25°C to +60°C -

Humidity Range: 5% to 95% non-condensing -

Power Supply: 24V DC (nominal, 18-32V DC range) -

Power Consumption: 6W (typical) -

Dimensions: 120mm x 100mm x 75mm (width x height x depth, fits AC500 rack) -

Weight: 0.4kg -

Certifications: CE, UL, cULus, RoHS

ABB PM5650-2ETH 1SAP141000R0278