Description

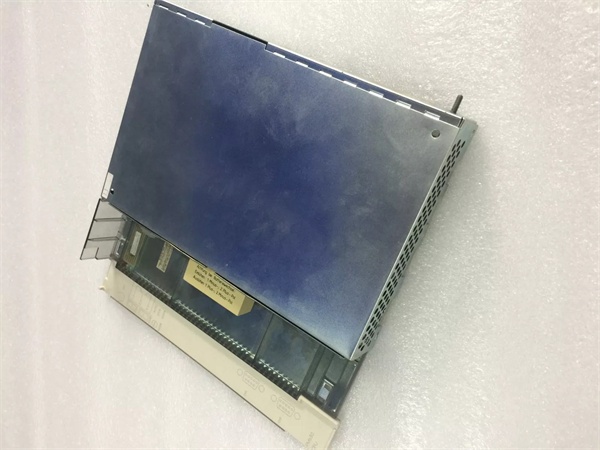

ABB PM630 3BSE000434R1

-

Model Number: PM630 3BSE000434R1 -

Manufacturer: ABB -

Product Type: PROFIBUS DP Communication Processor Module -

Communication Protocol: PROFIBUS DP (V1 compliant) -

Data Rate: 9.6 kbps to 12 Mbps (auto-negotiation) -

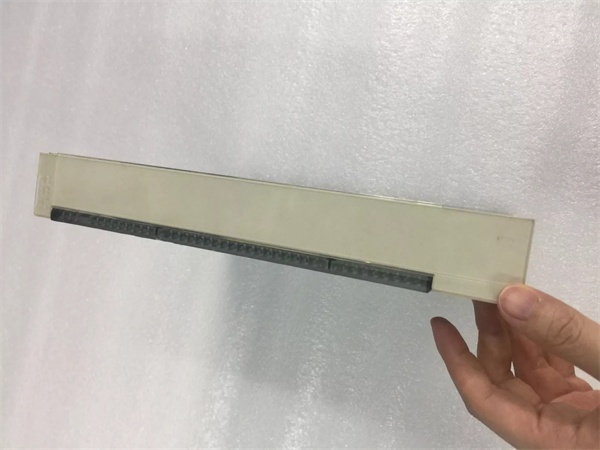

Number of Connections: 1 (DB9 connector) -

Power Supply: 24 V DC (±20%, from S800 I/O backplane) -

Isolation: 500 Vrms channel-to-backplane -

Operating Temperature: 0°C to +55°C -

Storage Temperature: -40°C to +70°C -

Dimensions: 45 mm (width) x 119 mm (height) x 112 mm (depth) -

Weight: Approximately 0.25 kg -

Certifications: CE, UL, cULus

ABB PM630 3BSE000434R1