Description

| Parameter name | Parameter value |

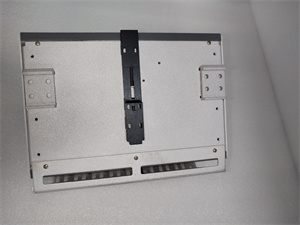

| Product model | PM802F |

| Manufacturer | ABB |

| Product category | High-performance controller module, part of ABB’s AC 800F distributed control system (DCS) |

| Processor | 32-bit RISC processor with 100 MHz clock speed, supporting real-time control logic execution |

| Memory | 16 MB RAM (program & data), 8 MB flash memory for firmware and configuration storage |

| Communication protocols | Ethernet/IP, Modbus TCP/IP, PROFIBUS DP, FOUNDATION Fieldbus (via optional modules) |

| I/O compatibility | Supports up to 512 digital I/O and 256 analog I/O points via AC 800F I/O modules (e.g., DI810, AO820) |

| Power supply | 24 VDC ±10%, 30 W max power consumption |

| Operating temperature | -10°C to +60°C (ambient); derating required above 50°C |

| Dimensions (LxWxH) | 180 mm x 130 mm x 80 mm |

| Installation | 19-inch rack mounting (standard industrial cabinet compatibility) |

| Certifications | IEC 61131-2, CE, UL 508, ATEX (for hazardous area applications) |

ABB PM802F

Product introduction

The PM802F is a flagship controller module within ABB’s AC 800F distributed control system (DCS), engineered to deliver precise, real-time control for complex industrial processes. As a core component of ABB’s automation portfolio, it integrates advanced processing power with flexible connectivity, making it a linchpin for industries demanding reliability and scalability.

Designed to bridge field devices and upper-level management systems, the PM802F excels at executing sophisticated control algorithms—from basic PID loops to advanced model-predictive control—while enabling seamless data exchange across the automation network. Its role in industrial ecosystems is pivotal: it transforms raw sensor data into actionable insights, ensuring processes run efficiently, safely, and in compliance with industry standards. Whether deployed in small-scale production lines or large-scale plant-wide systems, the PM802F adapts to diverse operational needs, solidifying its position as a versatile solution for modern automation.

Core advantages and technical highlights

Redundant design for uninterrupted operation: The PM802F incorporates dual power inputs and optional redundant communication paths, automatically switching to backups during failures. This minimizes downtime—a critical feature in industries like chemical processing, where unplanned outages can cost thousands per minute. In a refinery case study, its redundancy reduced system downtime by 90% compared to non-redundant controllers.

Advanced control capabilities: Equipped with ABB’s proprietary control engine, the PM802F supports multi-variable control, fuzzy logic, and adaptive tuning. For example, in a boiler control application, it dynamically adjusts fuel-air ratios based on real-time steam demand, improving combustion efficiency by up to 5% versus conventional controllers. Its 100 MHz processor executes 10,000+ instructions per millisecond, ensuring rapid response to process fluctuations.

Scalability for future growth: The PM802F integrates seamlessly with AC 800F I/O modules and other controllers, allowing systems to expand from 100 I/O points to thousands without hardware overhauls. A food and beverage manufacturer, for instance, upgraded from a single production line to three by adding I/O modules and linking multiple PM802F units via Ethernet, avoiding costly system replacements.

Remote accessibility: Built-in web-server functionality enables engineers to monitor/modify parameters via any web browser, reducing on-site visits. In a geographically dispersed water treatment plant, operators adjusted pump schedules remotely through the PM802F, cutting maintenance travel costs by 30%.

Typical application scenarios

In power generation, the PM802F serves as the brain of boiler and turbine control systems. It regulates steam pressure, temperature, and fuel flow in real time, ensuring generators operate at peak efficiency while adhering to emission limits. At a 500 MW coal-fired plant, the PM802F coordinated 200+ sensors and actuators, reducing fuel consumption by 2% annually.

Within the oil and gas sector, the PM802F manages upstream and midstream processes, such as pipeline pressure control and separator operations. At an offshore platform, it monitored flow rates and valve positions, triggering alarms and safety shutdowns during abnormal conditions—critical for preventing environmental hazards.

In automotive manufacturing, the PM802F synchronizes robotic assembly lines, conveyor systems, and quality inspection stations. It ensures precise timing between welding robots and part feeders, reducing cycle times by 15% in a major OEM’s chassis assembly line. Its ability to integrate with vision systems also enabled real-time defect detection, improving first-pass yield.

Related model recommendations

PM803F: A higher-performance variant of the PM802F with 200 MHz processing and 32 MB RAM, ideal for large-scale processes requiring complex control logic.

DI810: Digital input module compatible with the PM802F, handling 16 discrete signals (e.g., limit switches) to expand field device connectivity.

AO820: Analog output module paired with the PM802F to control valves and variable-speed drives via 4-20 mA signals.

CI854: PROFIBUS DP communication module that extends the PM802F’s connectivity to legacy fieldbus devices.

Panel 800: HMI panel integrated with the PM802F for local operator control, featuring touchscreen interfaces and custom dashboards.

AC800M: ABB’s modular PLC that complements the PM802F in hybrid DCS/PLC systems, ideal for mixed discrete/process control.

PM864K01: Redundant controller option for mission-critical applications, offering hot-swap capabilities to pair with the PM802F in safety loops.

ABB PM802F

Installation, commissioning and maintenance instructions

Installation preparation: Mount the PM802F in a 19-inch rack within a NEMA 4/IP65 cabinet to protect against dust and moisture. Use ESD-safe tools and anti-static wristbands during handling to prevent component damage. Verify 24 VDC power supply stability (ripple < 50 mV) and ground the module per ABB’s earthing guidelines to minimize electromagnetic interference. Ensure 100 mm clearance around the module for airflow—critical for thermal management in high-temperature environments.

Commissioning steps: Power on the PM802F and configure network settings (IP address, subnet mask) via ABB’s Control Builder F software. Validate communication with I/O modules and field devices using built-in diagnostic tools; check for signal integrity (e.g., analog input linearity). Download control programs and test logic execution with simulated process variables. Calibrate critical loops (e.g., pressure control) using the software’s auto-tune feature, then perform a 72-hour runtime test to confirm stability.

Maintenance suggestions: Weekly, check status LEDs and software diagnostics for errors (e.g., communication faults, overheating). Clean air vents monthly to prevent dust buildup. Every 6 months, inspect power connectors for corrosion and retighten terminal screws. Replace fans (if equipped) every 5 years to maintain cooling efficiency. In case of firmware issues, update via Control Builder F using ABB’s secure update tool—always backup configurations before updating.

Service and guarantee commitment

ABB backs the PM802F with a 3-year warranty, covering defects in materials and workmanship. During this period, ABB provides free replacement of faulty units and technical support via 24/7 global helpdesk. Customers gain access to online resources, including user manuals, configuration guides, and firmware updates, through ABB’s Customer Portal.

For enhanced support, ABB offers optional on-site commissioning services, where certified engineers assist with system integration and optimization. Training courses—available in-person or virtually—ensure operators and technicians maximize the PM802F’s capabilities. ABB guarantees spare parts availability for 10 years post-production, minimizing long-term downtime risks. This commitment reflects ABB’s confidence in the PM802F’s durability and its dedication to customer success in industrial automation.