Description

PM820-1: Product Overview

The module serves as a standalone process controller or expansion unit within ABB AC500 PLC-based automation systems, positioned in the control layer for small-to-medium process applications. Its role is to execute closed-loop control (e.g., temperature, pressure, flow regulation) by processing analog/digital signals from field instruments, running PID algorithms, and communicating with supervisory systems (HMI, DCS). In a typical architecture, it interfaces with ABB 800xA DCS via Ethernet or PROFIBUS, or operates independently with local HMI for decentralized control.

Core functionality includes processing 8 AI (4-20mA, 0-10V) and 4 AO (4-20mA) signals, 16 DI/DO (24V DC) for discrete control, and supporting multi-protocol communication (Ethernet/IP, PROFIBUS DP, Modbus RTU) for integration with diverse devices. It embeds a 32-bit ARM processor for real-time control, with 8MB flash memory for program storage and 4MB RAM for data buffering. The controller also provides built-in HMI capabilities (via optional keypad/display) and diagnostic tools (e.g., loop tuning, fault logging).

It belongs to the ABB AC500 PLC Series, a platform optimized for modular process control. Benefits of this series include seamless integration with ABB’s Automation Builder software for programming, hot-swappable I/O modules for minimal downtime, and compliance with IEC 61131-3 standards for programming languages (ST, LD, FBD). This series simplifies scaling from standalone controllers to full PLC systems, preserving engineering investment.

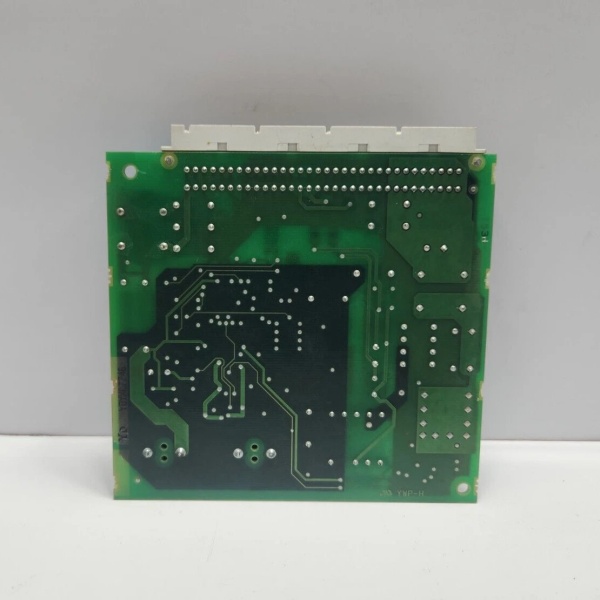

ABB PM820-1

PM820-1: Technical Specifications

-

Model Number: PM820-1

-

Manufacturer: ABB Ltd.

-

Product Type: Compact Process Controller

-

Processor: 32-bit ARM Cortex-M3 (80 MHz)

-

Memory: 8MB Flash, 4MB RAM

-

Analog Inputs: 8 channels (4-20mA, 0-10V, ±10V, RTD Pt100/Pt1000)

-

Analog Outputs: 4 channels (4-20mA, 0-10V)

-

Digital I/O: 16 channels (8 DI, 8 DO; 24V DC, 0.5A per DO)

-

Communication Protocols: Ethernet/IP, PROFIBUS DP V1, Modbus RTU, USB (programming)

-

Control Algorithms: PID (standard, cascade, ratio), on/off, custom logic (IEC 61131-3)

-

Operating Temperature: -20°C to +60°C

-

Power Supply: 24V DC (±10%, 15W max)

-

Dimensions: 120mm (H) x 100mm (W) x 80mm (D)

-

Weight: ~0.6kg

-

Certifications: CE, UL (cULus Listed), RoHS, ATEX Zone 2 (optional)

Core Features & Customer Value

The 32-bit ARM processor ensures deterministic control loop execution (≤10ms scan time), critical for applications like batch reactor temperature control where rapid adjustments prevent overshoot. For engineers, this enables tight process stability (±0.5% setpoint accuracy) with minimal tuning effort. Multi-protocol support (Ethernet, PROFIBUS, Modbus) eliminates the need for protocol converters, simplifying integration with legacy devices (e.g., Siemens S7-1200 PLCs) or modern HMIs in mixed-vendor environments.

Built-in PID algorithm libraries (cascade, ratio) reduce programming time for complex control strategies, such as maintaining steam-to-feed ratios in distillation columns. For maintenance teams, channel-level diagnostics (via ABB Automation Builder) flag faults like “AI 3 wire break” or “DO 5 overload,” reducing mean time to repair (MTTR). The compact design (0.6kg) and DIN rail mounting save panel space in retrofits, such as upgrading analog panel meters to digital control in food processing plants.

Hot-swappable I/O modules (compatible with AC500 series) allow incremental expansion without system shutdown, ideal for growing facilities like water treatment plants adding new sensors. The optional HMI keypad enables local parameter adjustment during commissioning, reducing reliance on laptop connections in remote locations.

ABB PM820-1

Typical Applications

In a brewery, the controller regulates fermentation tank temperature using 4 RTD inputs (Pt100) and 2 AO channels (heating valve control), with Ethernet communication to the central SCADA for recipe management. The PID cascade function maintains setpoints despite yeast activity variations.

At a municipal water pump station, it processes 8 AI signals (pressure, flow) from sensors and 4 DI (pump status), activating 4 DO (starter controls) via Modbus RTU to balance pump loads. The -20°C cold-start capability ensures operation in uninsulated pump houses.

In a small chemical batch reactor, the controller manages 2 AI (temperature, pH) and 2 AO (heater, agitator speed), with PROFIBUS DP linking to a legacy Siemens PLC for ingredient dosing. The built-in HMI displays real-time trends, enabling operators to adjust setpoints without a separate HMI panel.