Description

Detailed parameter table

| Parameter name | Parameter value |

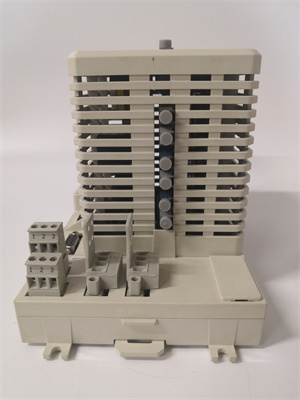

| Product model | PM825 3BSE010796R1 |

| Manufacturer | ABB |

| Product category | Programmable Automation Controller (PAC) |

| CPU performance | High – speed 32 – bit processor, capable of handling complex control algorithms with fast execution times |

| Memory | 128 MB of RAM for data storage and processing, 512 MB of flash memory for program storage |

| Input/Output (I/O) capacity | Supports a wide range of I/O modules, with expandable slots. Can handle up to [X] digital inputs, [X] digital outputs, [X] analogue inputs, and [X] analogue outputs |

| Communication interfaces | Ethernet for high – speed network connectivity, Modbus RTU for serial communication with other devices, CANopen for industrial network integration |

| Power supply | 24 V DC (±10%) input, with low power consumption to ensure energy – efficient operation |

| Operating temperature range | -20°C to +60°C, suitable for harsh industrial environments |

| Storage temperature range | -40°C to +85°C |

| Protection class | IP20 for basic protection against dust and solid objects, can be installed in standard control panels |

| Dimensions (LxWxH) | [Specific dimensions in mm], designed for compact installation in control cabinets |

| Weight | [Weight in kg], lightweight for easy handling during installation |

PM825 3BSE010796R1

Product introduction

The ABB PM825 3BSE010796R1 is a high – performance Programmable Automation Controller (PAC) that serves as the brain of industrial automation systems. ABB, a renowned global leader in power and automation technologies, has engineered this PAC to meet the diverse and demanding requirements of modern industrial processes.

This PAC is designed to seamlessly integrate into various industrial setups, providing intelligent control and monitoring capabilities. It interfaces with a multitude of sensors, actuators, and other devices within the industrial network. By collecting data from sensors, such as temperature, pressure, and position sensors, the PM825 can analyze this information using its powerful 32 – bit processor. Based on the analysis, it then generates appropriate control signals to actuators, such as motors, valves, and relays, ensuring that industrial processes operate smoothly, efficiently, and within the desired parameters. Whether it’s controlling a manufacturing line, a power generation plant, or a water treatment facility, the PM825 plays a pivotal role in optimizing industrial operations.

Core advantages and technical highlights

High – speed processing power: With its 32 – bit high – speed processor, the PM825 can execute complex control algorithms in milliseconds. In a high – speed packaging line, it can quickly adjust the speed of conveyor belts, sealing machines, and labeling equipment based on product flow and quality inspection results. This rapid processing ability reduces production bottlenecks and increases overall throughput, allowing manufacturers to meet high – volume production demands.

Abundant memory resources: The 128 MB of RAM and 512 MB of flash memory provide ample space for data storage and program execution. A large – scale chemical plant uses the PM825 to store historical process data, real – time sensor readings, and complex control programs. The sufficient memory ensures that the PAC can handle the data – intensive tasks associated with continuous process monitoring and control without any performance degradation.

Flexible I/O expansion: The expandable I/O slots enable the PM825 to adapt to different industrial applications. A food and beverage factory can add digital input modules to monitor the status of various switches and sensors on production equipment, and analogue output modules to control the speed of pumps and motors precisely. This flexibility allows for customized control solutions tailored to the specific needs of each industrial process.

Robust communication capabilities: The combination of Ethernet, Modbus RTU, and CANopen communication interfaces makes the PM825 highly compatible with other devices in an industrial network. A power generation station uses Ethernet to connect the PM825 to a central Supervisory Control and Data Acquisition (SCADA) system for real – time monitoring and control. Modbus RTU is used to communicate with older – generation devices, and CANopen is utilized for seamless integration with modern industrial automation components. This multi – protocol support ensures seamless data transfer and interoperability across the entire industrial ecosystem.

Energy – efficient operation: Operating on a 24 V DC power supply with low power consumption, the PM825 helps industrial plants reduce their energy costs. A textile mill with multiple PM825 – controlled production lines noticed a significant decrease in overall power consumption, contributing to both cost savings and a more sustainable operation.

Typical application scenarios

Manufacturing industry: In an automotive assembly plant, the PM825 controls the movement of robotic arms, conveyor systems, and welding equipment. It coordinates the complex operations involved in assembling car parts, ensuring precise positioning and timely execution of tasks. The PAC monitors sensor data from various parts of the assembly line, such as the position of car bodies on conveyors and the status of welding guns, and adjusts the operation of equipment accordingly. This results in improved production efficiency, reduced errors, and higher – quality vehicle assembly.

Power generation: A power plant uses the PM825 to control the operation of turbines, generators, and auxiliary equipment. It monitors parameters such as steam pressure, turbine speed, and generator voltage in real – time. Based on this data, the PAC adjusts the fuel supply to the boilers, the opening of valves in the steam system, and the excitation of generators to maintain stable power generation. In case of any abnormal conditions, the PM825 can quickly trigger safety mechanisms to protect the power – generating equipment and ensure grid stability.

Water treatment: In a municipal water treatment plant, the PM825 controls the pumps, valves, and chemical dosing systems. It monitors water quality parameters such as pH, turbidity, and chlorine levels using sensors. Depending on the sensor readings, the PAC adjusts the flow rate of water through treatment processes, the dosage of chemicals for disinfection and purification, and the operation of filtration systems. This ensures that the treated water meets the required quality standards before being supplied to consumers.

PM825 3BSE010796R1

Related model recommendations

PM810: A lower – cost variant with a slightly less powerful processor and reduced memory capacity. It is suitable for smaller – scale industrial applications, such as local control in a small – to – medium – sized manufacturing workshop or a decentralized water treatment unit.

PM830: An upgraded version with enhanced processing power, more memory, and additional communication options. It is ideal for large – scale, complex industrial plants, like those in the petrochemical industry, where high – speed data processing and extensive network connectivity are required.

DI810: ABB digital input module that can be paired with the PM825 to increase the number of digital input channels. It is useful for applications that require monitoring a large number of discrete signals, such as the status of multiple switches and sensors in a manufacturing line.

AO810: ABB analogue output module that can be connected to the PM825 to control analogue – controlled devices. In a process control application, it can be used to adjust the speed of variable – speed drives or the position of control valves precisely.

CI854: A communication interface module that can expand the communication capabilities of the PM825. It adds support for additional industrial communication protocols, such as Profibus – DP, which is widely used in European industrial automation systems.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the PM825 on a DIN rail or a suitable control panel using the provided mounting brackets. Ensure that the installation environment is clean, dry, and free from excessive electromagnetic interference. Connect the power supply wires to the appropriate terminals, following the color – coding or pin – out diagram provided in the user manual. Use a 24 V DC power supply with a capacity sufficient to meet the power requirements of the PAC and any connected I/O modules. Connect the communication cables (Ethernet, Modbus RTU, CANopen) to the respective ports, making sure the connections are secure. Before powering on the module, double – check all connections to avoid short – circuits and incorrect wiring.

Maintenance suggestions: Regularly inspect the PM825 for any signs of physical damage, such as cracks or loose connections. Clean the module periodically using a soft, dry cloth to remove dust and debris, especially in dusty industrial environments. Check the communication links to ensure that data is being transmitted correctly. In case of abnormal control behavior, first check the integrity of the connected sensors and actuators, as well as the calibration of any analogue devices. If the problem persists, refer to the troubleshooting guide provided by ABB. Update the firmware of the PM825 regularly to benefit from the latest features, bug fixes, and security enhancements. Spare parts such as I/O modules and communication interfaces should be kept on hand for quick replacement in case of component failures.

Service and guarantee commitment

ABB offers a comprehensive service and guarantee for the PM825 3BSE010796R1. The product comes with a standard 2 – year warranty, during which any manufacturing defects will be covered. ABB’s global technical support team is available 24/7 to provide assistance with installation, commissioning, and troubleshooting. They can offer detailed guidance and solutions to ensure the proper operation of the module. ABB also ensures the long – term availability of spare parts, minimizing downtime in case of component failures. Additionally, customers can access ABB’s online resources for firmware updates, product documentation, and technical training. This commitment reflects ABB’s confidence in the quality and reliability of the PM825 and its dedication to providing a seamless experience for industrial customers.