Description

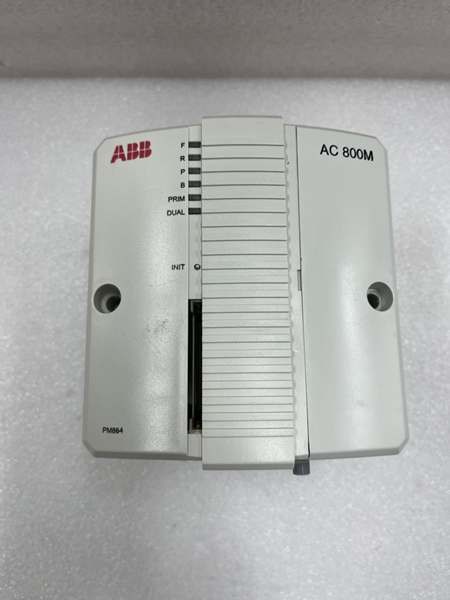

ABB AC800M PM864

-

Model Number: PM864 -

Manufacturer: ABB -

Product Type: Main Processor Unit -

Power Supply: 24 VDC nominal (range 19.2-31.2 VDC) -

Number of Processors: 2 (for redundant operation) -

Application Memory: 32 MB Flash -

Communication Ports: Two RS-232C, one Ethernet (RJ45) -

Supported Protocols: S9001, MODBUS TCP, TCP/IP -

Operating Temperature: 0°C to +60°C -

Storage Temperature: -40°C to +70°C -

Dimensions (HxWxD): 240 x 115 x 45 mm (approx.) -

Weight: 0.8 kg (approx.) -

Humidity: 5% to 95% non-condensing -

Processor Clock Speed: 133 MHz

ABB AC800M PM864