Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | PP886 3BSE092980R1 |

| Manufacturer | ABB |

| Product category | High – performance operator panel |

| Display size | 15.4 inches |

| Resolution | 1280 × 800 pixels (16:10) |

| Display type | TFT – LCD with LED backlight |

| Brightness | 450 cd/m² |

| Touch screen type | Resistive |

| Processor | ARM9 (1 GHz) |

| Main memory | 1 GB |

| External storage media | 2 GB SSD, 1.5 GB free for application storage |

| Ethernet | 2 × 10/100 base – T (shielded RJ45) |

| USB ports | 2 × USB 2.0 (500 mA each) |

| Serial port | 1 × RS232, 1 × RS422/485, 1 × RS485 (if com 2 is RS485) |

| Mounting type | Panel mount, VESA 75 × 75 |

| Protection rating | IP65 (front), IP20 (rear) |

| Operating temperature | -10 °C to +60 °C |

| Storage temperature | -20 °C to +70 °C |

| Relative humidity | 5% – 85% (non – condensed) |

| Power supply | 24 V DC (18 – 32 VDC) |

| Power consumption | 31.2 W |

| Dimensions (W × H × D) | 410 × 286 × 61 mm |

| Cut – out dimensions (W × H) | 394 × 270 mm |

| Weight | 3.85 kg |

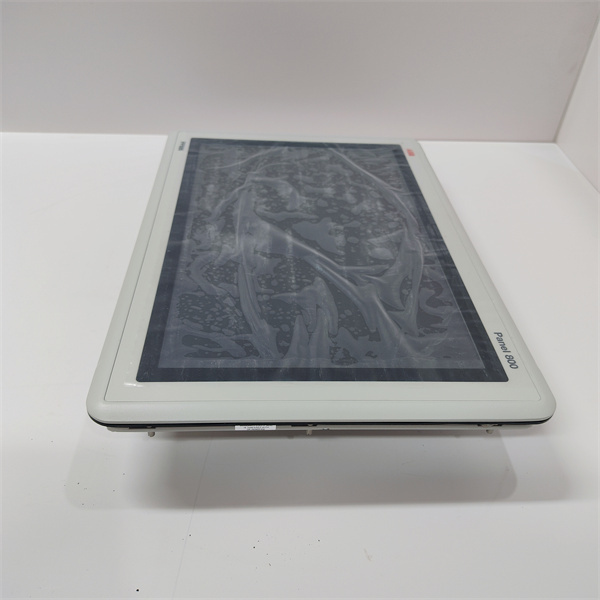

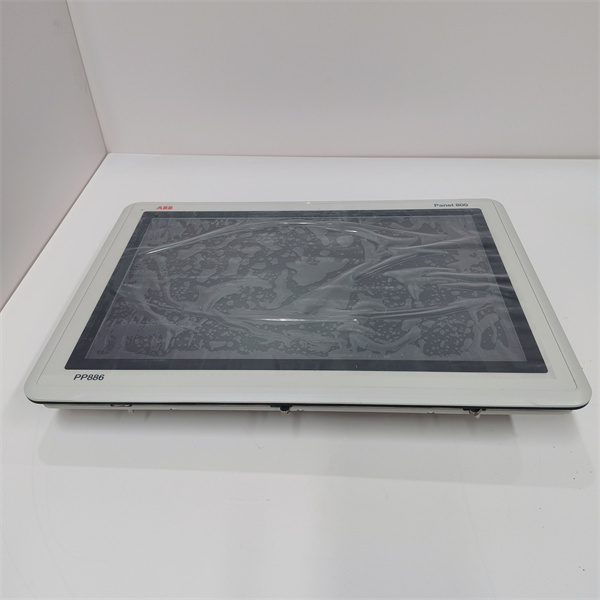

ABB PP886 3BSE092980R1

Product introduction

The ABB PP886 3BSE092980R1 is a standout operator panel within the Panel 800 family, engineered to meet the rigorous demands of modern industrial automation. With its 15.4 – inch display, it offers an expansive visual workspace for operators to manage and monitor complex processes. This panel is a sophisticated human – machine interface (HMI), designed to streamline operations in diverse industrial settings, from large – scale manufacturing plants to intricate power generation facilities.

Built on ABB’s expertise in automation technology, the PP886 combines a user – friendly interface with powerful processing capabilities. Its resistive touch screen, paired with a high – resolution TFT – LCD display, ensures that operators can interact with the system precisely, even in environments where gloves are required. The ARM9 1 GHz processor, along with 1 GB of main memory, enables smooth multitasking and quick response times, making it suitable for applications that demand real – time data processing and control.

Core advantages and technical highlights

Generous display area: The 15.4 – inch display of the PP886 provides a significantly larger viewing area compared to smaller – sized panels. This is particularly beneficial in applications where multiple data streams need to be visualized simultaneously. In a petrochemical plant control room, for example, operators can view detailed process flow diagrams, real – time sensor readings, and alarm notifications all on one screen, reducing the need to switch between different views and enhancing overall situational awareness.

High – resolution graphics: With a resolution of 1280 × 800 pixels, the PP886 delivers sharp and clear graphics. Whether it’s displaying high – definition process visualizations or complex graphs representing production trends, the panel ensures that every detail is visible. This high – resolution display is crucial for accurate data interpretation, especially in industries where precision is paramount, such as semiconductor manufacturing.

Reliable connectivity: Equipped with 2 Ethernet ports (10/100 base – T shielded RJ45), 2 USB 2.0 ports, and a comprehensive set of serial ports, the PP886 offers versatile connectivity options. It can easily integrate with a wide range of industrial devices, including programmable logic controllers (PLCs), sensors, and other HMIs. In a smart factory setup, the panel can communicate with multiple PLCs controlling different production lines, aggregating data and providing a unified view for operators.

Robust construction: The PP886 features an IP65 – rated front, which provides excellent protection against dust and water splashing. This makes it suitable for use in harsh industrial environments, such as food and beverage production facilities where sanitation and protection against moisture are critical. The white powder – coated aluminum frame not only adds to its durability but also gives it a sleek and professional appearance.

Typical application scenarios

In large – scale manufacturing industries, such as automotive assembly plants, the PP886 serves as a central control hub. Operators can use the panel to monitor the status of multiple production lines, adjust production parameters, and receive real – time feedback on product quality. The large display allows for the simultaneous visualization of various aspects of the production process, such as conveyor belt speeds, robotic arm movements, and quality control metrics.

For power generation plants, whether they are coal – fired, gas – fired, or renewable energy – based, the PP886 is an invaluable tool. Operators can use it to monitor the performance of generators, turbines, and other critical equipment. The panel can display real – time data on power output, voltage levels, and equipment health, enabling operators to make informed decisions to ensure efficient and reliable power generation. In a wind farm control room, for instance, the PP886 can show the status of multiple wind turbines, including their power output, blade angles, and maintenance requirements.

In the pharmaceutical industry, where strict quality control and hygiene standards are essential, the PP886 plays a vital role. It can be used to control and monitor the manufacturing process, ensuring that all production steps comply with regulatory requirements. The IP65 – rated front protects the panel from dust and potential contamination in cleanroom environments, while the high – resolution display allows operators to closely monitor critical process parameters, such as temperature, pressure, and ingredient dosages.

ABB PP886 3BSE092980R1

Related model recommendations

ABB PP877K: A 10.4 – inch operator panel with multi – touch capabilities. It is a more compact option compared to the PP886 and may be suitable for applications where space is limited or where a more cost – effective solution is required. However, the PP886 offers a larger display and different connectivity options, making it more suitable for complex, data – intensive applications.

ABB PP895: A high – end operator panel with even more advanced features. It may have a higher – resolution display, more powerful processing capabilities, and enhanced environmental resistance. While the PP886 is a robust and capable panel, the PP895 is designed for applications where the highest level of performance and functionality is needed, such as in mission – critical control centers.

ABB AC800M 3BSE018105R1: A controller that pairs well with the PP886. Together, they can form a powerful automation solution, enabling seamless communication and control between the operator interface and the underlying control system. The AC800M controller can process and manage the data received from the PP886, ensuring efficient operation of industrial processes.

ABB CI854A 3BSE022469R1: A Profibus DP adapter that can extend the connectivity of the PP886. This is useful in scenarios where the panel needs to communicate with legacy devices or systems that use the Profibus DP protocol. It allows for the integration of the PP886 into existing industrial networks, providing greater flexibility in system design.

Installation, commissioning and maintenance instructions

Installation preparation: Before installation, ensure that the mounting location is clean, dry, and free from excessive vibrations. The panel can be mounted using the panel – mount method or via VESA 75 × 75 brackets. Verify that the power supply voltage is within the specified range of 24 V DC (18 – 32 VDC). Use shielded cables for Ethernet and serial connections to minimize electromagnetic interference. The cut – out dimensions of 394 × 270 mm should be accurately prepared in the mounting surface.

Maintenance suggestions: Regularly clean the resistive touch screen of the PP886 using a soft, non – abrasive cloth. Avoid using harsh chemicals that could damage the screen surface. Check the connectivity of all cables periodically to ensure they are secure and free from corrosion. Monitor the panel’s temperature during operation to ensure it remains within the -10 °C to +60 °C range. Update the panel’s firmware regularly to access new features, improve performance, and address any security vulnerabilities. If any issues arise, refer to the ABB user manual or contact ABB’s technical support for assistance.

Service and guarantee commitment

ABB provides a 12 – month factory warranty for the PP886 3BSE092980R1, covering manufacturing defects. Their global technical support team is available to assist customers with installation, commissioning, and troubleshooting. Customers can access online resources, including detailed user manuals, technical documentation, and software updates. In case of any issues, ABB’s support team can provide remote assistance or, if necessary, dispatch trained technicians for on – site support. This commitment to service ensures that customers can rely on the PP886 for their industrial automation needs and have peace of mind knowing that ABB stands behind the quality of their product.