Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | PPC322BE1 HIEE300900R1 |

| Manufacturer | ABB |

| Product Category | Industrial Panel PC |

| Display | 21.5-inch TFT-LCD, 1920×1080 resolution, 16.7 million colors |

| Touch Screen | Projected capacitive, 10-point multi-touch, 5 million operations |

| Front Panel Protection | IP65 |

| Housing Material | Aluminum alloy front bezel, steel chassis |

| Dimensions (W×H×D) | 520mm×320mm×85mm |

| Weight | Approximately 8.2kg |

| Processor | Intel Core i5 (8th Gen) |

| Memory | 8GB DDR4 RAM (expandable to 32GB) |

| Storage | 256GB SSD (expandable to 1TB) |

| Operating System | Windows 10 IoT Enterprise |

| Communication Interfaces | 2×Gigabit Ethernet, 4×USB 3.0, 1×USB Type-C, 2×RS485, 1×HDMI |

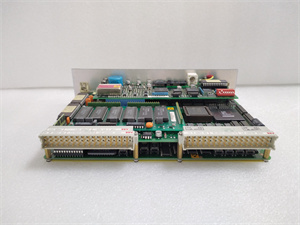

| Expansion Slots | 1×PCIe x4, 1×mPCIe |

| Power Supply | 24V DC (18-30V DC), typical consumption 5.5A |

| Operating Temperature | 0°C to 50°C |

| Storage Temperature | -20°C to 60°C |

| Relative Humidity | 5-95% (non-condensing) |

| Certifications | CE, UL 61010, ATEX Zone 2, IEC 60068 |

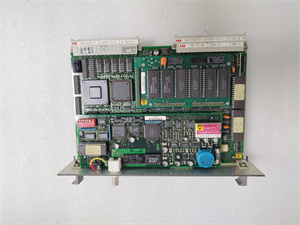

ABB PPC322BE1 HIEE300900R1

Product Introduction

ABB PPC322BE1 HIEE300900R1 is a high-performance industrial panel PC designed for demanding automation environments requiring both HMI functionality and advanced computing capabilities. Unlike the PP886H 3BSE069297R1 which focuses primarily on visualization, this panel PC combines a 21.5-inch interactive display with powerful processing to run complex applications directly at the machine level.

As part of ABB’s industrial computing lineup, PPC322BE1 HIEE300900R1 bridges the gap between traditional HMIs and server-grade computing, enabling real-time data processing, edge analytics, and direct integration with IoT platforms. Its Windows 10 IoT operating system supports custom software development, making it ideal for smart manufacturing environments where the PP886H 3BSE069297R1‘s fixed functionality would be insufficient.

Core Advantages and Technical Highlights

Industrial-grade computing power:

Equipped with an Intel Core i5 processor and 8GB RAM, PPC322BE1 HIEE300900R1 handles advanced applications like machine vision processing and predictive analytics—tasks beyond the capabilities of the PP886H 3BSE069297R1. In automotive quality control, it can run image recognition software to inspect welds in real time while simultaneously displaying production metrics.

Flexible software environment:

Unlike the proprietary HMI software of PP886H 3BSE069297R1, this panel PC runs Windows 10 IoT, supporting off-the-shelf and custom applications. Food and beverage producers can install ERP connectors to directly link production data with inventory systems, eliminating manual data entry and reducing errors by up to 40%.

Expandable architecture:

With PCIe and mPCIe slots, PPC322BE1 HIEE300900R1 accommodates specialized hardware like motion control cards or wireless modules—expansion options not available on the PP886H 3BSE069297R1. In semiconductor fabrication, this allows integration of specialized measurement cards for monitoring cleanroom conditions alongside standard HMI functions.

Rugged design with smart features:

The aluminum alloy construction and IP65 protection ensure durability in harsh environments, while intelligent thermal management maintains performance without noisy fans. This makes it suitable for pharmaceutical cleanrooms where the PP886H 3BSE069297R1 would require additional enclosures to meet hygiene standards.

ABB PPC322BE1 HIEE300900R1

Typical Application Scenarios

In smart factories, ABB PPC322BE1 HIEE300900R1 serves as a localized data hub, collecting information from connected machines via OPC UA, processing it with edge analytics software, and displaying real-time KPIs on its 21.5-inch screen. Unlike the PP886H 3BSE069297R1, it can run machine learning algorithms to predict maintenance needs, reducing unplanned downtime by analyzing vibration patterns from connected sensors.

Within logistics automation centers, this panel PC controls robotic picking systems while running warehouse management software locally. Operators use the multi-touch interface to monitor inventory levels, adjust pick paths, and troubleshoot equipment—all on a single device that communicates directly with both PLCs and cloud-based inventory systems, a level of integration beyond the capabilities of traditional HMIs.

In water treatment facilities, PPC322BE1 HIEE300900R1 combines SCADA visualization with advanced water quality analysis software. Its processing power enables real-time calculation of chemical dosages based on changing inlet conditions, while the rugged design withstands the humid environment better than standard office PCs.

Related Model Recommendations

- PP886H 3BSE069297R1: A dedicated HMI with similar display size but focused on visualization rather than computing, suitable when advanced processing isn’t needed.

- PPC215BE1 HIEE300899R1: 15.6-inch variant of PPC322BE1 HIEE300900R1for space-constrained applications requiring the same processing power in a smaller form factor.

- AC500 PLCs: ABB’s programmable controllers that integrate seamlessly with PPC322BE1 HIEE300900R1for complete control systems.

- ABB Ability™ EdgeInsight: Software suite optimized for PPC322BE1 HIEE300900R1enabling advanced analytics and cloud connectivity.

- PPC322BE1-EXT: Expansion module adding PoE ports and isolated I/O to PPC322BE1 HIEE300900R1for connecting cameras and sensors.

- CP600 Series: Compact HMIs that can be paired with PPC322BE1 HIEE300900R1as secondary displays in distributed systems.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing ABB PPC322BE1 HIEE300900R1, ensure the mounting surface can support its 8.2kg weight and provides adequate airflow. Use M6 screws with 3-4Nm torque for secure installation. Connect to a stable 24V DC power supply with proper grounding. Configure BIOS settings for industrial operation (disable sleep modes, enable watchdog timer) before deploying. Position the unit to avoid direct sunlight on the display and ensure the touch screen remains accessible for operator interaction.

Maintenance suggestions: Clean the touch surface of PPC322BE1 HIEE300900R1 with a microfiber cloth and 70% isopropyl alcohol. Perform monthly backups of the SSD to external storage. Check all connections quarterly for tightness, especially in vibrating environments. Update operating system and drivers semi-annually using ABB’s industrial software repository. If experiencing performance issues, monitor system resources via Windows Task Manager to identify resource-intensive applications. Replace the CMOS battery every 5 years using ABB-specified components to maintain BIOS settings.

Service and Guarantee Commitment

ABB provides a 3-year warranty for PPC322BE1 HIEE300900R1, covering manufacturing defects and component failures under normal operation. Our technical support team offers specialized assistance for software configuration and system integration, with 24-hour response times for critical issues.

We provide factory-certified repair services using genuine components, ensuring restored performance meets original specifications. For mission-critical applications, ABB offers extended warranty options including priority technical support and rapid replacement service (48-hour turnaround). Training programs are available for both hardware maintenance and software development on this platform, ensuring customers maximize their investment in PPC322BE1 HIEE300900R1.