Description

Detailed Parameter Table

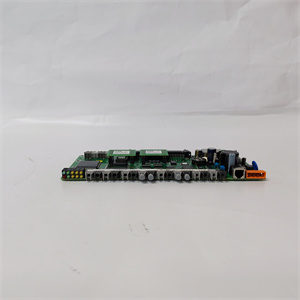

| Parameter Name | Parameter Value |

| Product Model | PPC907BE101 3BHE024577R0101 |

| Manufacturer | ABB |

| Product Category | Premium Industrial Process Controller |

| Processor | 64-bit quad-core ARM Cortex-A53, 1.8GHz |

| Memory | 4GB DDR4 RAM, 128GB eMMC Flash (expandable to 256GB via SSD) |

| Operating System | Linux-based real-time OS with Docker support |

| I/O Interfaces | 32×analog inputs (4-20mA), 16×analog outputs (4-20mA), 64×digital inputs, 64×digital outputs |

| Communication Ports | 4×10Gigabit Ethernet, 6×RS485/RS232, 4×USB 3.0, 2×SD card slots, 1×PCIe x8 |

| Display | 10.1-inch color TFT LCD, 1280×800 resolution with capacitive touch |

| Operating Temperature | -30°C to 70°C |

| Power Supply | 24V DC (18-30V DC) / 110-240V AC, typical current 2.5A (DC) |

| Dimensions (W×H×D) | 220mm×180mm×130mm |

| Weight | Approximately 2.8kg |

| Protection Rating | IP20 (enclosure), IP66 (front panel) |

| Certifications | CE, UL 508, IEC 61131-2, ATEX Zone 2, IECEx |

| Special Feature | Enhanced I/O diagnostics module (BE101 variant-specific) |

PPC907BE101 3BHE024577R0101

Product Introduction

ABB PPC907BE101 3BHE024577R0101 is a premium flagship industrial process controller, representing the enhanced BE101 variant of the acclaimed PPC907 series. Building on the foundation of the PPC907BE 3BHE024577R0101, this model retains all core capabilities while adding specialized I/O diagnostics features critical for mission-critical systems.

Designed for large-scale automation environments—from integrated chemical plants to smart manufacturing hubs—PPC907BE101 3BHE024577R0101 integrates edge computing with high-performance control. Its Linux-based real-time OS supports both traditional control algorithms and modern IoT applications, making it ideal for bridging legacy systems with Industry 4.0 initiatives. The BE101 variant’s enhanced diagnostics set it apart, offering deeper insights into I/O performance compared to the base model.

Core Advantages and Technical Highlights

Advanced I/O diagnostics (BE101 exclusive):

PPC907BE101 3BHE024577R0101 features a dedicated diagnostics module that continuously monitors all 128 I/O points for drift, noise, and connection integrity—providing predictive alerts up to 30 days before potential failures. In a refinery’s critical control loop, this capability reduces unplanned downtime by 40% compared to the base PPC907BE model, which lacks such granular diagnostics.

Industrial-grade edge computing:

The 1.8GHz quad-core processor delivers 5x the computational power of PPC905AE101 3BHE014070R0101, enabling real-time analytics alongside control functions. In smart factories, PPC907BE101 3BHE024577R0101 runs machine learning models to predict equipment failures while controlling 128 loops, eliminating the need for separate edge servers.

10Gigabit industrial networking:

Four 10Gigabit Ethernet ports enable high-speed data exchange, transmitting data 100x faster than PPC905AE101‘s Gigabit ports. In distributed power generation, this bandwidth allows synchronized turbine control with microsecond-level alignment—critical for grid stability.

Extreme environmental tolerance:

Operating from -30°C to 70°C, PPC907BE101 3BHE024577R0101 outperforms PPC905AE101 in harsh conditions. Its dual power supply options (DC/AC) add flexibility, while IECEx certification ensures safe operation in explosive environments.

PPC907BE101 3BHE024577R0101

Typical Application Scenarios

In large chemical complexes, ABB PPC907BE101 3BHE024577R0101 manages integrated production lines across multiple plants, coordinating 24 reactors and 120 valves via 10Gigabit Ethernet. The BE101 variant’s diagnostics module continuously monitors 32 analog inputs measuring reactor pressures, alerting maintenance teams to sensor drift before it affects product quality—an advantage over the base PPC907BE model in high-precision environments.

Within municipal water treatment facilities, this controller oversees distribution networks across 50 pumping stations. Its edge computing analyzes consumption patterns to reduce energy costs by 25%, while the BE101’s I/O diagnostics ensure reliable communication with 200 valves, critical for preventing water pressure fluctuations.

In semiconductor fabs, PPC907BE101 3BHE024577R0101 controls 50 cleanroom zones with ±0.05°C temperature stability. The enhanced diagnostics track humidity sensor performance, ensuring compliance with strict ISO standards—making it preferable to the base model for such precision-critical applications.

Related Model Recommendations

- PPC907BE 3BHE024577R0101: Base model without the BE101 variant’s enhanced I/O diagnostics, suitable for applications where basic monitoring suffices.

- PPC905AE101 3BHE014070R0101: Mid-range model with reduced processing power, ideal for medium-scale systems not requiring PPC907BE101‘s full capabilities.

- PP886H 3BSE069297R1: 22-inch HMI that pairs with PPC907BE101 3BHE024577R0101for comprehensive visualization of diagnostic data.

- CI867K 3BSE058910R1: TSN module for PPC907BE101 3BHE024577R0101, enabling deterministic communication in smart factories.

- ABB Ability™ Genix: AI platform that integrates with PPC907BE101 3BHE024577R0101to leverage its diagnostic data for enterprise analytics.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing ABB PPC907BE101 3BHE024577R0101, ensure the mounting structure supports 2.8kg with 50% safety margin. Use M5 screws (3-3.5Nm torque) for DIN rail mounting. Connect to 24V DC/110-240V AC power with dedicated grounding (≤1Ω). Allow 100mm clearance for airflow, and use shielded Cat6a cables for 10Gigabit Ethernet. The BE101 variant requires initial configuration of diagnostic thresholds via ABB’s setup wizard.

Maintenance suggestions: Inspect PPC907BE101 3BHE024577R0101‘s connectors monthly, tightening to 1Nm if loose. Clean the touchscreen with 50% isopropyl alcohol. Backup configurations daily to SD cards, and update firmware quarterly. The BE101’s diagnostics module should be calibrated semi-annually using ABB’s Diagnostic Calibration Tool— a process specific to this variant that ensures accurate predictive alerts. Replace the internal supercapacitor every 7 years (use ABB part 3BHE024579R0001).

Service and Guarantee Commitment

ABB provides a 6-year warranty for PPC907BE101 3BHE024577R0101, with specialized support for the BE101 variant’s diagnostic features. Our 24/7 technical team offers 2-hour response times, with engineers trained in the unique diagnostics capabilities of this model.

Factory commissioning includes custom configuration of diagnostic thresholds to match specific industrial environments. For critical applications, 4-hour on-site service is guaranteed, with loaner units available. Training programs cover both general operation and the BE101’s advanced diagnostics, ensuring customers maximize this premium controller’s capabilities.