Description

PPD113B03-26-100110: Product Overview

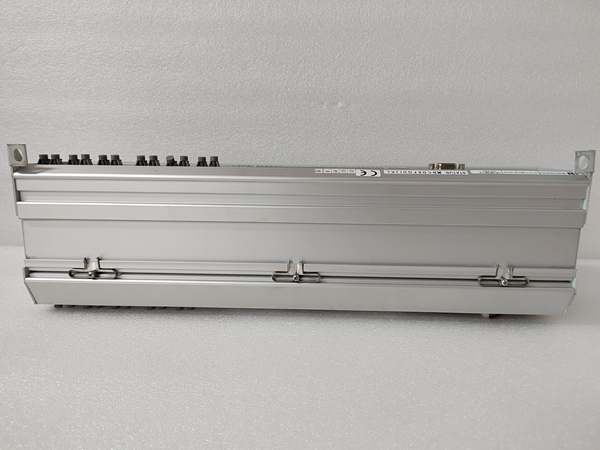

The ABB PPD113B03-26-100110 is a high-performance industrial controller from ABB’s AC 800PEC series, designed for demanding process automation applications. As the core component of the AC 800PEC system, it combines advanced computing power, flexible I/O integration, and robust communication capabilities to enable precise control and monitoring of industrial processes.

Role in Automation Systems:

Positioned as the “brain” of the AC 800PEC ecosystem, the PPD113B03-26-100110 performs three primary functions:

-

Process Control: Executes complex control algorithms (e.g., PID, model predictive control) to regulate variables like temperature, pressure, and flow in industrial processes.

-

Data Acquisition: Collects data from field devices (sensors, actuators) via connected I/O modules, providing real-time visibility into process status.

-

Communication Hub: Acts as a gateway between the AC 800PEC system and higher-level systems (e.g., SCADA, MES), enabling data exchange and remote monitoring.

Core Functionality:

-

High-Speed Processing: The 750 MHz RISC processor with a 64-bit floating-point unit (FPU) ensures fast execution of control algorithms, critical for time-sensitive applications like power generation and chemical processing.

-

Flexible I/O Integration: Supports a wide range of I/O modules (digital, analog, specialty) to accommodate diverse field device requirements, making it adaptable to various industrial environments.

-

Modular Design: The AC 800PEC system’s modular architecture allows for easy expansion or modification of I/O configurations, ensuring scalability as operational needs evolve.

Platform Benefits (AC 800PEC Series):

The PPD113B03-26-100110 leverages ABB’s AC 800PEC platform, which is renowned for:

-

Reliability: Industrial-grade components and a rugged design ensure 24/7 operation in harsh environments (e.g., high temperature, vibration).

-

Scalability: Supports expansion from small (10 I/O points) to large (1000+ I/O points) systems, adapting to growing operational needs.

-

Integration: Seamlessly integrates with ABB’s other automation products (e.g., drives, HMIs), reducing setup time and effort.

ABB PPD113B03-26-100110

Technical Specifications

Model Number: PPD113B03-26-100110

Manufacturer: ABB

Product Type: Industrial Controller

-

Processor: 750 MHz RISC (64-bit IEEE FPU)

-

Communication Protocols: Modbus, PROFIBUS, Ethernet/IP (supports multiple industrial networks)

-

I/O Compatibility: Connects to AC 800PEC I/O modules (digital/analog/specialty)

-

Operating Temperature: -20°C to +60°C (-4°F to 140°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F)

-

Humidity: 5–95% non-condensing

-

Dimensions (Depth×Height×Width): 145 mm × 450 mm × 100 mm (5.71 in × 17.72 in × 3.94 in)

-

Weight: 2.59 kg (5.71 lbs)

-

Certifications: CE, UL (inferred from ABB industrial product standards)

Core Features & Customer Value

1. High-Performance Processing for Complex Control Tasks:

The 750 MHz RISC processor with a 64-bit FPU enables fast execution of complex control algorithms, ensuring precise regulation of industrial processes. For example, in a power plant, this processor can handle real-time adjustments to turbine speed, maintaining optimal efficiency and reducing fuel consumption.

2. Flexible I/O Integration for Diverse Applications:

The controller’s support for multiple I/O module types (digital, analog, specialty) allows it to adapt to various field device requirements. In a chemical plant, this flexibility enables integration with pH sensors, pressure transmitters, and control valves, providing a unified control solution for the entire process.

3. Modular Design for Scalability:

The AC 800PEC system’s modular architecture allows for easy expansion or modification of I/O configurations. For instance, a water treatment facility can add more I/O modules to monitor additional sensors as the plant expands, without replacing the entire control system.

4. Robust Communication for Remote Monitoring:

Support for multiple communication protocols (Modbus, PROFIBUS, Ethernet/IP) enables seamless integration with higher-level systems (e.g., SCADA, MES). This allows operators to monitor process status remotely, reducing the need for onsite maintenance and improving operational efficiency.

ABB PPD113B03-26-100110

Typical Applications

The ABB PPD113B03-26-100110 is widely used in industries requiring reliable process automation:

-

Power Generation:

-

Controls turbine speed, boiler pressure, and generator output in thermal power plants.

-

Example: In a coal-fired power plant, the controller adjusts the fuel flow to the boiler based on real-time temperature and pressure data, maintaining optimal efficiency.

-

-

Chemical Processing:

-

Regulates chemical reactions by controlling variables like temperature, pressure, and flow rate.

-

Example: In a petrochemical refinery, the controller monitors the distillation column’s temperature and adjusts the reflux ratio to ensure consistent product quality.

-

-

Water Treatment:

-

Manages the filtration and purification process by controlling pumps, valves, and chemical dosing.

-

Example: In a municipal water treatment plant, the controller adjusts the amount of chlorine added to the water based on pH and turbidity data, ensuring safe drinking water.

-

-

Energy Distribution:

-

Controls the flow of electricity in power grids, ensuring stable distribution to consumers.

-

Example: In a substation, the controller monitors the voltage and current in the transmission lines and adjusts the transformer taps to maintain optimal voltage levels.

-