Description

PPD113B03R2060: Product Overview

The ABB PPD113B03R2060 is a high-performance automation processor module belonging to ABB’s AC 800PEC family—ABB’s flagship control system for industrial automation. Designed for mission-critical applications, it acts as the “brain” of the AC 800PEC system, executing control logic, processing sensor data, and managing communication between distributed I/O modules, field devices (e.g., sensors, actuators), and enterprise-level上位 systems (e.g., SCADA, MES).

Role in Automation Systems:

Positioned as the core controller in ABB’s AC 800PEC architecture, the PPD113B03R2060 enables seamless integration of high-speed processes (e.g., power electronics, robotics) with slower supervisory tasks (e.g., cooling loops, equipment monitoring). It replaces traditional PLC-DCS hybrid architectures by consolidating control functions into a single, scalable platform—reducing complexity and improving system reliability.

Core Functionality:

-

High-Speed Processing: Equipped with a 750 MHz RISC processor and 64-bit FPU, the module delivers microsecond-level response times for real-time control tasks (e.g., motor speed regulation, process variable adjustment).

-

Modular I/O Support: Connects to ABB’s AnyIO system via fiber-optic links (up to 36 bidirectional links), supporting a wide range of I/O modules (analog, digital, specialty) for flexible system expansion.

-

Multi-Protocol Communication: Supports Ethernet, Modbus, and Profibus protocols, enabling interoperability with third-party devices (e.g., Siemens PLCs, Schneider sensors) and enterprise systems.

-

Redundancy Options: Available in single or redundant configurations (with backup processors and power supplies) for fail-safe operation in critical applications (e.g., power generation, chemical processing).

Platform Benefits (AC 800PEC Family):

-

Scalability: Modular design allows users to add I/O modules, communication interfaces, or redundant components as operational needs grow—avoiding costly system overhauls.

-

Ruggedness: Industrial-grade components and a wide operating temperature range (-40°C to +85°C) ensure reliable operation in harsh environments (e.g., factories, substations).

-

Ease of Programming: Compatible with ABB’s Control Builder M (a IEC 61131-3 compliant tool) and MATLAB/Simulink for model-based design—reducing programming time and errors.

ABB PPD113B03R2060

Technical Specifications

Model Number: PPD113B03R2060

Manufacturer: ABB

Product Type: Automation Processor Module

-

Processor: 750 MHz RISC with 64-bit IEEE FPU

-

Input Voltage: 3-phase 380–415 VAC (±10%)

-

Output Voltage: 48 VDC (regulated)

-

Output Current: Maximum 150 A

-

Efficiency: ≥92% (typical)

-

Communication Interfaces:

-

Ethernet (10/100/1000 Mbps)

-

Modbus RTU/TCP

-

Profibus-DP (up to 12 Mbps)

-

-

I/O Expansion: Up to 36 bidirectional fiber-optic links (AnyIO system)

-

Operating Temperature: -40°C to +85°C

-

Storage Temperature: -55°C to +100°C

-

Humidity: 5–95% non-condensing

-

Protection Rating: IP20 (front panel)

-

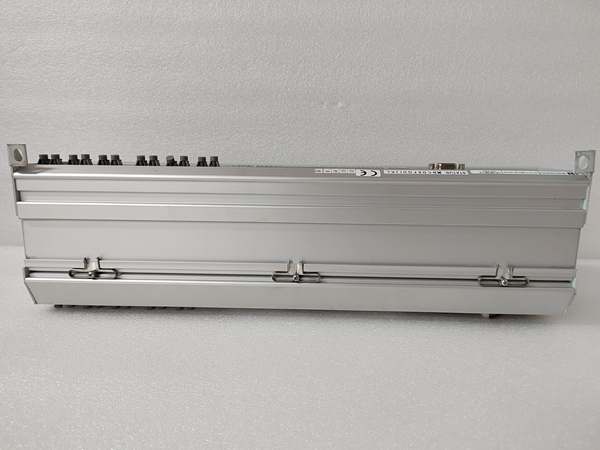

Dimensions (W×H×D): 100 mm × 450 mm × 145 mm

-

Weight: 2.59 kg (net)

-

Certifications: CE, UL, RoHS, ATEX (optional)

Core Features & Customer Value

1. High-Performance Processing for Real-Time Control:

The PPD113B03R2060’s 750 MHz RISC processor and 64-bit FPU enable it to handle complex mathematical calculations (e.g., PID tuning, motion control) in microseconds—critical for applications like robotic welding, high-speed packaging, or power converter control. For customers, this means improved process accuracy, reduced cycle times, and enhanced product quality.

2. Modular Design for Scalability and Flexibility:

ABB’s AnyIO system allows users to connect a wide range of I/O modules (analog, digital, thermocouple, RTD) to the PPD113B03R2060 via fiber-optic links. This modularity eliminates the need for proprietary I/O systems—customers can mix and match ABB and third-party devices to meet specific application needs. Additionally, the module’s compact size (100 mm × 450 mm × 145 mm) saves cabinet space compared to traditional PLCs.

3. Multi-Protocol Communication for Seamless Integration:

Support for Ethernet, Modbus, and Profibus protocols ensures the PPD113B03R2060 can communicate with virtually any device in an industrial automation system—from legacy sensors to modern SCADA systems. For example, a customer using Siemens S7-1500 PLCs can integrate them with the PPD113B03R2060 via Profibus-DP, avoiding the need for protocol converters. This reduces integration costs and simplifies system architecture.

4. Redundancy for Fail-Safe Operation:

The PPD113B03R2060 is available in redundant configurations (with a backup processor and power supply) for applications where downtime is unacceptable (e.g., power plants, water treatment facilities). If the primary processor fails, the backup takes over seamlessly—ensuring continuous operation and preventing costly outages.

ABB PPD113B03R2060

Typical Applications

The ABB PPD113B03R2060 is widely used in industries requiring high-reliability automation and real-time control:

-

Power Generation and Distribution:

-

Controls gas turbines, steam turbines, and generators in power plants.

-

Monitors and adjusts voltage, current, and frequency in substations.

-

Example: In a natural gas power plant, the PPD113B03R2060 manages the fuel-to-air ratio in gas turbines—optimizing efficiency and reducing emissions.

-

-

Manufacturing (Automotive, Electronics):

-

Controls robotic arms for welding, painting, and assembly in automotive plants.

-

Manages high-speed packaging lines in food and beverage factories.

-

Example: In an automotive assembly line, the PPD113B03R2060 coordinates six-axis robots to weld car frames—ensuring precise alignment and consistent weld quality.

-

-

Chemical and Petrochemical Processing:

-

Regulates temperature, pressure, and flow in chemical reactors.

-

Controls valves and pumps in distillation columns.

-

Example: In a petrochemical refinery, the PPD113B03R2060 adjusts the flow of crude oil into a distillation column—maintaining product purity and minimizing waste.

-

-

Water and Wastewater Treatment:

-

Manages pumps and valves in water distribution systems.

-

Monitors water quality (pH, turbidity) in treatment plants.

-

Example: In a municipal water treatment plant, the PPD113B03R2060 controls the addition of chlorine to drinking water—ensuring compliance with safety standards.

-