Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | PPE091A101 3BHE044481R0101 |

| Manufacturer | ABB |

| Product category | Industrial power supply module (redundant) |

| Input voltage | 110-240 V AC (single-phase) / 220-480 V AC (three-phase) |

| Output voltage | 24 V DC ±0.5% |

| Output current | 40 A (total), 10 A per channel (4 isolated channels) |

| Efficiency | >92% @ full load |

| Redundancy | 1+1 hot-swappable configuration support |

| Protection features | Overvoltage, overcurrent, short circuit, overtemperature |

| Operating temperature | -25°C to 70°C |

| Power consumption | Max 1200 W |

| Protection rating | IP20 (module), IP54 (with enclosure) |

| Mounting type | Cabinet mount (DIN rail) |

| Dimensions | 160mm × 220mm × 130mm |

| Certifications | CE, UL, IEC 60950-1, IEC 61010-1 |

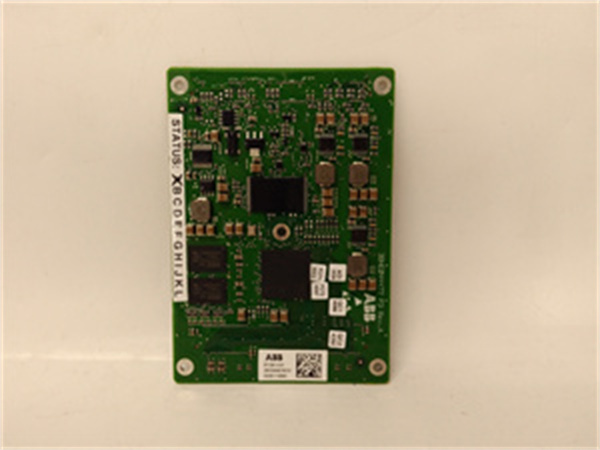

ABB PPE091A101 3BHE044481R0101

Product introduction

The PPE091A101 3BHE044481R0101 is a high-performance redundant power supply module from ABB, engineered to deliver stable and reliable 24 V DC power to critical industrial automation components. As a key component in ABB’s power management portfolio, this module supplies power to robot control units like the KUC321AE HIEE300698R1, servo drive interfaces such as the 3HAC14550-408A, and PLC systems including the PCD235A101 3BHE032025R0101, ensuring uninterrupted operation in mission-critical environments.

Unlike standard power supplies, the PPE091A101 features redundant design, isolated output channels, and robust protection mechanisms, making it ideal for applications where power continuity is non-negotiable—from automotive production lines to semiconductor fabrication facilities. Whether deployed in harsh industrial settings or controlled cleanrooms, this module ensures consistent power delivery, minimizing the risk of downtime caused by power-related faults.

Core advantages and technical highlights

Redundant power architecture: The PPE091A101 supports 1+1 hot-swappable redundancy, allowing two modules to operate in parallel with automatic failover. In an automotive paint shop, this means if one power supply fails, the second unit seamlessly takes over within 5 ms, preventing disruption to the KUC321AE robot controller and avoiding costly production stoppages. The redundant design also enables module replacement without powering down the system, reducing maintenance-related downtime.

Multi-voltage input flexibility: With support for both single-phase (110-240 V AC) and three-phase (220-480 V AC) inputs, the module adapts to diverse industrial electrical systems. This flexibility is particularly valuable in global manufacturing facilities, where the same power supply can be deployed in regions with different electrical standards—eliminating the need for custom configurations. In a multinational electronics plant, for example, the PPE091A101 can operate on 230 V AC single-phase in Europe and 480 V AC three-phase in North America without hardware modifications.

Isolated output channels with precise regulation: The module’s four isolated 24 V DC output channels (10 A each) provide galvanic isolation (2.5 kV AC) from both the input and other channels, preventing ground loops and electromagnetic interference from affecting sensitive devices like the AI880-1 analog module. Each channel maintains ±0.5% voltage regulation, ensuring stable power for components with strict voltage tolerance requirements—such as the communication circuits in the 500CIM05 1MRB150077R1/B module.

Comprehensive protection mechanisms: Equipped with overvoltage, overcurrent, short circuit, and overtemperature protection, the PPE091A101 safeguards connected devices from electrical faults. In a food processing plant, if a DTCC901B digital module develops a short circuit, the power supply’s short circuit protection activates within 100 µs, isolating the fault to a single channel while maintaining power to other critical components like the robot gripper controls. The module also includes thermal shutdown to prevent damage during extreme temperature conditions.

High efficiency and energy savings: With an efficiency rating of over 92% at full load, the PPE091A101 minimizes power loss and heat generation, reducing cooling requirements in control cabinets. In a large-scale logistics center with 50+ robot cells, this efficiency translates to significant energy savings—lowering operational costs by up to 15% compared to conventional power supplies. The module’s fanless design (for loads <70%) further reduces energy consumption and eliminates a common point of failure.

Typical application scenarios

In a semiconductor fabrication cleanroom, the PPE091A101 3BHE044481R0101 provides redundant power to a cluster of IRB 6700 robots controlled by KUC321AE units. Its isolated channels supply power to sensitive vision systems (via DSQC 1031 modules) and robot servo drives (via 3HAC14550-408A interfaces), preventing cross-talk that could disrupt micron-level positioning. The module’s ability to operate in temperatures up to 70°C allows installation in compact cleanroom cabinets, while its redundancy ensures uninterrupted production of high-value microchips.

In an automotive assembly plant’s welding cell, the power supply feeds 24 V DC to the PCD235A101 PLC, 500CIM05 communication module, and safety interlock sensors (connected to DTCC901B modules). During a sudden voltage spike from the plant’s electrical system, the module’s overvoltage protection clamps the output to 26 V, protecting the PLC’s logic circuits from damage. Its redundant configuration ensures welding robots continue operating even if one power supply module requires replacement, maintaining production throughput.

ABB PPE091A101 3BHE044481R0101

Related model recommendations

PPE092A102 3BHE044482R0102: A higher-capacity variant with 60 A total output, ideal for large robot cells with multiple controllers.

KUC321AE HIEE300698R1: ABB’s robot control unit powered by the PPE091A101 for reliable operation.

3HAC14550-408A: ABB’s servo drive interface that receives stable power from the module.

PCD235A101 3BHE032025R0101: ABB’s PLC that relies on the power supply for consistent performance.

500CIM05 1MRB150077R1/B: ABB’s communication module that integrates with the PPE091A101 in networked systems.

S800 I/O Backplane: ABB’s backplane system that distributes power from the module to I/O modules.

HMI80: ABB’s touchscreen panel that displays power supply status and diagnostics from the PPE091A101.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the PPE091A101 3BHE044481R0101 on a DIN rail in the control cabinet, ensuring at least 150mm clearance for ventilation. For redundant configurations, install two modules side-by-side with 50mm spacing. Connect input power using 4mm² shielded cable, with appropriate overcurrent protection (10A for single-phase, 5A for three-phase). Wire output channels to connected devices, using 2.5mm² cable for currents >5A. Ground all shields at the module end. Required tools include a torque screwdriver, wire strippers, and a multimeter. Power off the system during installation.

Commissioning steps: After installation, verify input voltage (matches selected range) and output voltage (24 V DC ±0.5%) using a calibrated multimeter. Test redundancy by disconnecting one module in a 1+1 configuration and confirming the second unit maintains output. Configure overcurrent trip points for each channel using ABB’s Power Manager software (via USB). Simulate a short circuit on one channel (using a test resistor) to verify protection activation without affecting other channels. Log all test results for compliance documentation.

Maintenance suggestions: Inspect monthly for loose connections, dust accumulation, and LED status (power: green, fault: red, redundancy: blue). Clean ventilation slots with compressed air to prevent overheating. Check output voltage stability quarterly under full load conditions. In redundant systems, swap modules semi-annually to ensure both units remain operational. Replace the module if protection features activate repeatedly without external faults, or if output voltage regulation exceeds ±1%. Use only ABB-certified replacements to maintain safety and performance certifications.

Service and guarantee commitment

The PPE091A101 3BHE044481R0101 comes with a 5-year warranty from installation, covering manufacturing defects and ensuring compliance with published performance specifications. ABB guarantees technical support response within 4 hours for critical applications, with on-site service available in 72 hours for qualified industrial facilities. The module includes free access to configuration software tools for the first 3 years. Extended service contracts offer annual preventive maintenance, calibration verification, and priority support, ensuring reliable operation throughout its 10-year design lifespan. Customers receive dedicated online resources, including wiring diagrams, troubleshooting guides, and safety certifications specific to this model.