Description

Detailed parameter table

| Parameter name | Parameter value |

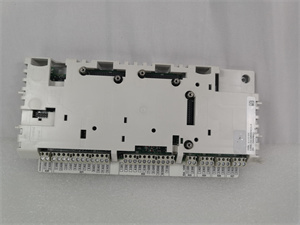

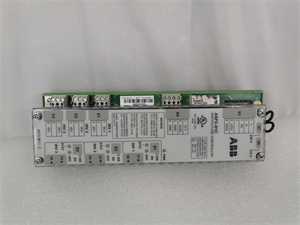

| Product model | RDCU-12C |

| Manufacturer | ABB |

| Product category | Drive control unit |

| Compatible drives | ACS800 series industrial drives (0.75kW to 560kW) |

| Supply voltage | 24V DC ±10% |

| Power consumption | Typical: 8W, Maximum: 12W |

| Communication interfaces | RS485 (Modbus RTU), Fibre optic (for drive-to-drive communication) |

| Digital inputs | 6 programmable digital inputs |

| Digital outputs | 3 programmable relay outputs (NO/NC) |

| Analog inputs | 2 (0-20mA or 4-20mA, 0-10V) |

| Analog outputs | 1 (0-20mA, 0-10V) |

| Operating temperature | -10°C to 50°C |

| Storage temperature | -40°C to 70°C |

| Dimensions (W×H×D) | 145mm×110mm×170mm |

| Weight | Approximately 350g |

| Protection rating | IP20 (when mounted inside drive cabinet) |

| Certifications | CE, UL, CSA, IEC 61800-5-1 |

RDCU-12C.

Product introduction

The ABB RDCU-12C is a compact, high-performance drive control unit designed as a key component of ABB’s ACS800 series industrial drives. As the “brain” of the drive system, it manages motor control functions, processes feedback signals, and enables communication with external systems. This control unit plays a critical role in ensuring precise motor operation across various industrial applications.

ABB RDCU-12C supports a wide range of motor types, including induction motors and permanent magnet motors, making it versatile for different industrial needs. Its integration with the ACS800 drive platform allows for seamless control of speed, torque, and direction, while its modular design simplifies upgrades and maintenance. Whether used in pumps, fans, conveyors, or complex machinery, the RDCU-12C delivers reliable performance and energy efficiency.

Core advantages and technical highlights

Advanced motor control algorithms

The RDCU-12C incorporates ABB’s proprietary Direct Torque Control (DTC) technology, which provides precise torque and speed regulation even at low speeds. This ensures smooth operation of motors in applications like precision conveyors, where maintaining consistent torque is critical for product handling. Unlike traditional V/F control methods, DTC allows the RDCU-12C to respond to load changes in milliseconds, reducing energy waste and mechanical stress.

Flexible communication capabilities

Equipped with RS485 (Modbus RTU) and fibre optic interfaces, the RDCU-12C enables seamless integration into industrial networks. The fibre optic port supports high-speed drive-to-drive communication (up to 1Mbps), making it ideal for multi-drive systems such as those found in paper mills or rolling mills. For larger automation setups, it can connect to PLCs or SCADA systems via Modbus, allowing centralized monitoring and control—eliminating the need for separate communication modules.

Robust design for industrial environments

Built to withstand harsh conditions, the RDCU-12C operates reliably in temperatures ranging from -10°C to 50°C, with protection against electrical noise and voltage fluctuations. Its conformal-coated circuit boards resist dust and moisture, ensuring longevity in environments like food processing plants or wastewater facilities. This durability reduces downtime and maintenance costs compared to less rugged control units.

User-friendly programming and diagnostics

The RDCU-12C features intuitive programming via ABB’s Drive composer software, which allows engineers to configure parameters, simulate operations, and troubleshoot issues offline. Its built-in diagnostic tools monitor drive performance in real time, flagging potential problems such as overheating or voltage irregularities through the digital outputs. This proactive monitoring helps prevent unexpected failures, particularly valuable in critical applications like power plant auxiliaries.

RDCU-12C.

Typical application scenarios

Water and wastewater treatment

In water pumping stations, the ABB RDCU-12C controls ACS800 drives powering large pumps, regulating flow rates based on demand. Its DTC technology ensures smooth starts and stops, reducing water hammer in pipelines—a common issue in municipal water systems. The control unit’s analog inputs connect to pressure sensors, allowing it to adjust pump speed automatically to maintain consistent pressure, saving up to 30% in energy costs compared to fixed-speed systems. In wastewater treatment plants, it manages aeration blowers, adjusting speed to match oxygen demand in biological treatment tanks.

Manufacturing conveyors

In automotive assembly lines, the RDCU-12C coordinates multiple conveyor belts through its fibre optic communication port, ensuring synchronized movement of car parts. Its precise speed control prevents product jams, while the programmable digital inputs integrate with sensors to detect part presence and trigger speed changes. For example, when a sensor detects a bottleneck, the RDCU-12C slows upstream conveyors to avoid accumulation, maintaining production efficiency. The unit’s diagnostic features also alert maintenance teams to worn motor bearings, preventing unplanned line stops.

HVAC systems in large facilities

In commercial buildings or industrial complexes, the RDCU-12C controls fan and pump motors in HVAC systems, adjusting speed based on temperature or pressure readings. In a shopping mall, it modulates air handling unit fans to match occupancy levels, reducing energy use during off-peak hours. The Modbus interface connects to building management systems, allowing facility managers to monitor energy consumption and optimize performance remotely. The RDCU-12C’s ability to operate in variable load conditions ensures comfort while minimizing energy waste.

Related model recommendations

- RDCU-02C: A basic variant of the RDCU-12Cwith simplified features, suitable for small drives (0.75kW to 75kW) where advanced control is unnecessary. It lacks fibre optic communication but retains core DTC functionality.

- RDCU-32C: A higher-performance version of the RDCU-12Cdesigned for large drives (above 560kW). It adds Ethernet connectivity and enhanced diagnostics for complex applications like marine propulsion systems.

- ACS800-01-0003-3+P901: An ACS800 drive package pre-installed with the RDCU-12C, ideal for quick deployment in fan or pump applications. The P901 option includes a control panel for local operation.

- CI854A 3BSE013232R1: ABB’s Profibus-DP communication module, which can be paired with the RDCU-12Cto add Profibus connectivity in industrial networks requiring this protocol.

- PM864K01 3BSE022496R1: ABB’s PLC module that integrates with the RDCU-12Cin distributed control systems, enabling advanced automation logic for multi-drive setups.

- RINT-5511C: A line filter recommended for use with the RDCU-12Cin environments with high electromagnetic interference, ensuring stable operation of the control unit and connected drive.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the ABB RDCU-12C, ensure the drive cabinet is clean, dry, and free from conductive debris. Verify that the 24V DC power supply is stable (within ±10%) and properly fused (1A recommended). Use a torque wrench to secure the unit to the drive’s internal mounting rails (torque: 0.5-0.7Nm). When connecting wiring, separate power cables from signal cables to minimize interference—route analog/digital signals through shielded cables, grounding the shields at both ends. For fibre optic connections, use ABB-approved cables (part number 3HAC025357-001) and avoid sharp bends (minimum radius: 50mm).

Maintenance suggestions

Inspect the RDCU-12C quarterly for loose connections or signs of corrosion, particularly on terminal blocks. Clean dust from the unit using compressed air (max 50psi), taking care not to damage components. Check the conformal coating for cracks—if damaged, contact ABB service to reapply coating, as this protects against moisture. During commissioning, use Drive composer to back up parameter settings to a USB drive; store backups in a secure location for quick recovery. If faults occur, refer to the error codes displayed on the drive’s control panel (connected via the RDCU-12C’s digital outputs) to identify issues like overcurrent or communication failures. Replace faulty components with ABB-genuine parts only, as third-party components may compromise performance.

Service and guarantee commitment

ABB provides a 2-year warranty for the RDCU-12C, covering defects in materials and workmanship under normal operating conditions. Our global technical support team offers 24/7 assistance for installation, programming, and troubleshooting, with response times within 4 hours for critical issues.

Factory-certified repair services ensure that any faulty RDCU-12C units are restored to original specifications using genuine components. For mission-critical applications, ABB offers a rapid replacement service (next-business-day delivery in major regions) to minimize downtime. Training programs are available for both basic operation and advanced programming of the RDCU-12C, ensuring customers maximize its capabilities and extend the lifespan of their ACS800 drive systems.