Description

| Parameter name | Parameter value |

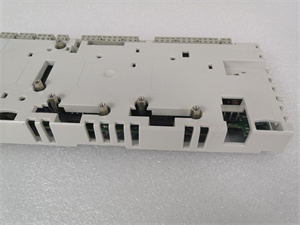

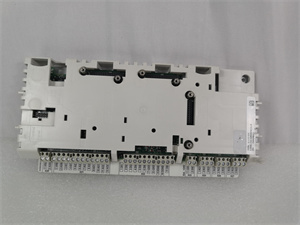

| Product model | RDCU – 12C + CABLES |

| Manufacturer | ABB |

| Product category | Drive control unit and associated cables for ACS800 inverters |

| Rated voltage | 24 V DC |

| Rated current | 1 A |

| Communication protocol | Supports protocols like PROFIBUS, CANopen, MODBUS (through communication interface on the unit) |

| Input channels | 3 analog inputs – differential, common mode voltage ±15 V, galvanically isolated as a group; one ±0(2) to 10 V, resolution 12 bit, two 0(4) to 20 mA, resolution 11 bit; 7 digital inputs – galvanically isolated as a group (can be split in two groups), input voltage 24 V DC, filtering (hw) time 1 ms |

| Output channels | 2 analog outputs – 0(4) to 20 mA, resolution 10 bit; 3 digital (relay) outputs – changeover contact, 24 V DC or 115/230 V AC, max. continuous current 2 A |

| Reference voltage output | ±10 V ±0.5%, max. 10 mA |

| Auxiliary power supply output | +24 V ±10%, max. 250 mA |

| Dimensions (approx., for RDCU – 12C) | 120 mm x 80 mm x 40 mm |

| Weight (approx., for RDCU – 12C) | 0.5 kg |

| Mounting method | Suitable for installation within control cabinets, designed to integrate with ACS800 – series inverter setups |

| Cable type and length | Cables are specifically designed to interface with the RDCU – 12C unit, ensuring proper signal transmission and connection to relevant components within the ACS800 inverter system. Lengths may vary based on typical installation requirements in industrial setups |

ABB RDCU-12C+CABLES

Product introduction

The ABB RDCU – 12C + CABLES is a pivotal component in the ACS800 inverter ecosystem. The RDCU – 12C, a compact yet powerful drive control unit, serves as the nerve center for ACS800 inverters, orchestrating a wide range of functions crucial for motor control and system operation. It is designed to precisely regulate the performance of motors, enabling seamless adjustments in speed, torque, and other vital parameters.

This unit is equipped with an array of input and output channels, allowing for comprehensive connectivity with various external devices. The analog and digital inputs can interface with sensors that monitor factors like motor temperature, while the outputs can be used to control relays, actuators, or provide feedback signals to other parts of the control system. The included cables in the RDCU – 12C + CABLES package are engineered to ensure reliable and efficient communication between the RDCU – 12C and other components within the ACS800 inverter setup. They are designed to withstand the rigors of industrial environments, minimizing signal interference and ensuring stable data transmission.

Core advantages and technical highlights

Precise motor control capabilities

The RDCU – 12C is armed with advanced control algorithms. It can execute vector control and direct torque control techniques, which are instrumental in achieving high – precision motor control. In industrial applications such as precision manufacturing, where motors need to operate with tight tolerances, the RDCU – 12C can regulate motor speed to within a fraction of a percentage of the set value. This precision not only improves product quality but also enhances the overall efficiency of the production process.

Versatile communication options

With support for multiple communication protocols like PROFIBUS, CANopen, and MODBUS, the RDCU – 12C can easily integrate into diverse industrial control networks. In a large – scale factory with a mix of different control systems, it can communicate with the plant’s central control system as well as other intelligent devices. This allows for centralized monitoring and control, enabling operators to manage motor operations remotely and in real – time.

Robust input and output configuration

The 3 analog inputs, with their differential design and high – resolution capabilities, can accurately measure a wide range of signals. For example, they can precisely detect minute changes in temperature or pressure sensors. The 7 digital inputs, which are galvanically isolated, are highly resistant to electrical noise, ensuring reliable operation even in electrically noisy industrial environments. The output side, with 2 analog outputs and 3 digital (relay) outputs, can drive a variety of loads, from solenoid valves to indicating lights, providing flexibility in controlling different aspects of the motor – driven system.

Durable and compact design

The RDCU – 12C’s compact dimensions of 120 mm x 80 mm x 40 mm make it easy to fit into tight – space control cabinets, which is a common requirement in many industrial setups. Despite its small size, it is built to be rugged and durable, able to withstand the harsh environmental conditions often found in industrial settings, such as temperature fluctuations, humidity, and vibrations. The included cables are also designed with durability in mind, using high – quality materials to ensure long – term performance.

Typical application scenarios

Manufacturing industry

In manufacturing plants, the ABB RDCU – 12C + CABLES is extensively used. For instance, in an automotive assembly line, it controls the motors that power conveyor belts. The precise speed control capabilities of the RDCU – 12C ensure that the conveyor belts move at a consistent and accurate speed, facilitating smooth assembly operations. The unit’s ability to interface with sensors can also be used to detect any jams or malfunctions in the conveyor system, triggering immediate corrective actions. In a textile manufacturing plant, it controls the motors of spinning machines, where the accurate regulation of motor speed is crucial for producing high – quality yarn.

HVAC systems

In large – scale heating, ventilation, and air – conditioning (HVAC) systems, the RDCU – 12C plays a vital role. It controls the motors of fans and compressors. By adjusting the speed of these motors based on temperature and humidity sensors’ inputs, the RDCU – 12C helps optimize the energy consumption of the HVAC system. For example, during periods of low demand, it can reduce the fan speed, saving electricity without compromising the comfort level. The unit’s reliable communication capabilities also allow it to be integrated into a building management system, enabling centralized control and monitoring of the HVAC system.

Water and wastewater treatment

In water treatment plants, the RDCU – 12C + CABLES is used to control the motors of pumps and agitators. The analog inputs can receive signals from sensors that measure water quality parameters such as pH, turbidity, and chlorine levels. Based on these inputs, the RDCU – 12C can adjust the speed of the pumps to ensure the proper flow of water through the treatment process. The digital outputs can be used to control the operation of valves and switches, enabling automated control of the treatment process. In wastewater treatment plants, it can control the motors of sludge pumps and aerators, ensuring efficient treatment of wastewater.

ABB RDCU-12C+CABLES

Related model recommendations

RDCU – 02C: Another drive control unit from ABB. It is similar in function to the RDCU – 12C but may have different input/output configurations or communication capabilities. It can be used in applications where the specific requirements for I/O channels are different from those of the RDCU – 12C. For example, if an application requires more analog outputs and fewer digital inputs, the RDCU – 02C might be a more suitable choice.

ACS800 – 01: An ABB inverter that pairs well with the RDCU – 12C. The RDCU – 12C serves as the control unit for the ACS800 – 01 inverter, enabling precise motor control. The combination is often used in smaller – scale industrial applications where a single – drive solution is sufficient.

ACS880: A more advanced series of ABB inverters. While the RDCU – 12C is primarily designed for the ACS800 series, in some cases, with the right adaptations and additional components, it can be used in combination with the ACS880 series to provide certain control functions. This can be useful in scenarios where an upgrade of the inverter system is planned, but some legacy control components like the RDCU – 12C need to be reused.

DI810: A digital input module from ABB. In cases where an industrial setup requires an expansion of digital input capabilities beyond what the RDCU – 12C offers, the DI810 can be added to the system. It can be used to interface with additional sensors or switches, providing more input data for the overall control system where the RDCU – 12C is the central control unit.

AI810: An analog input module. If an application needs to monitor more analog signals than the 3 analog inputs on the RDCU – 12C can handle, the AI810 can be integrated into the system. It can measure various analog parameters such as temperature, pressure, and flow rate, and feed this data into the RDCU – 12C – based control system for further processing.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the ABB RDCU – 12C + CABLES, ensure that the installation environment is clean, dry, and free from excessive dust and electromagnetic interference. Mount the RDCU – 12C unit securely within the control cabinet, following the provided installation guidelines. Use appropriate tools such as screwdrivers and wire strippers to connect the cables. When connecting the power supply, double – check that the 24 V DC supply is within the specified tolerance and has proper grounding. Verify that the cables are routed neatly and are not likely to be pinched or damaged during normal operation.

Commissioning

Power on the RDCU – 12C unit and use ABB’s dedicated software or a compatible programming device to configure the communication settings, input/output parameters, and control algorithms. Set the appropriate communication protocol (e.g., PROFIBUS, CANopen, MODBUS) based on the requirements of the overall control system. Calibrate the analog inputs and outputs using precision signal generators and multimeters to ensure accurate readings and outputs. Test the digital inputs and outputs by simulating real – world conditions, such as activating sensors or relays. Verify that the unit can communicate effectively with other components in the ACS800 inverter system, such as the motor and other control modules.

Maintenance suggestions

Regularly inspect the RDCU – 12C unit and the cables for any signs of physical damage, such as cracks, frayed wires, or loose connections. Check the temperature of the unit during operation to ensure it is within the specified range; overheating can indicate a potential problem. Periodically clean the unit to remove dust, which can accumulate and affect its performance. In case of a malfunction, use the diagnostic tools available in the ABB software to identify the root cause. If a component needs replacement, use genuine ABB spare parts, such as replacement cables or internal circuit boards, to ensure the continued reliable operation of the RDCU – 12C + CABLES system. Keep a record of maintenance activities and any issues encountered for future reference.

Service and guarantee commitment

ABB stands firmly behind the RDCU – 12C + CABLES with a comprehensive service and guarantee commitment. The product comes with a standard 12 – month warranty, covering any defects in materials and workmanship. During this period, if the unit or cables fail due to manufacturing issues, ABB will provide a free replacement. ABB offers 24/7 technical support through its global helpdesk, ensuring that customers can get assistance whenever they encounter problems.

Customers can access a wealth of online resources, including detailed user manuals, software updates, and troubleshooting guides, on ABB’s official website. Optional services such as on – site installation and commissioning, as well as operator training, are available to help customers make the most of the product. ABB also ensures the availability of spare parts for an extended period, typically several years after the product’s release, providing long – term support and peace of mind to industrial users. This commitment reflects ABB’s confidence in the quality and reliability of the RDCU – 12C + CABLES product.