Description

Detailed parameter table

| Parameter name | Parameter value |

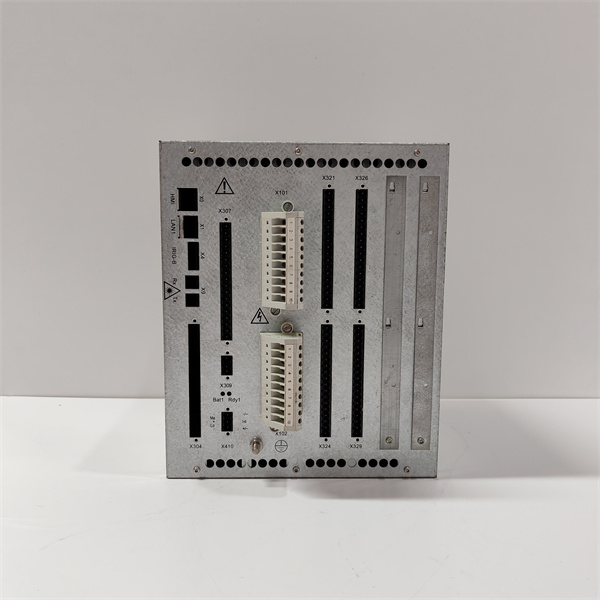

| Product model | REC650 1MRK008514-AB |

| Manufacturer | ABB |

| Product category | Numerical transformer protection relay |

| Rated voltage | 110 – 240 V AC/DC |

| Current input | 1 A or 5 A (software-selectable) for primary and secondary windings |

| Voltage input | 100 V/220 V (phase-to-phase), 57.7 V/127 V (phase-to-ground) |

| Frequency range | 50/60 Hz (automatic detection) |

| Protection functions | |

| Differential protection: Core feature with high-speed operation (≤20 ms) for internal transformer faults, using restraint characteristics to avoid false trips during external faults. | |

| Overcurrent protection: 3-phase directional and non-directional overcurrent with 4 stages, covering both primary and backup protection needs. | |

| Earth fault protection: Restricted and unrestricted earth fault detection, critical for isolating ground faults in transformer windings or connected circuits. | |

| Thermal overload protection: Models transformer winding temperature based on current and ambient conditions, preventing overheating during overloads. | |

| Buchholz relay interface: Monitors gas accumulation in oil-immersed transformers, triggering alarms or trips for incipient faults. | |

| Voltage protection: Overvoltage, undervoltage, and voltage unbalance detection to safeguard against abnormal grid conditions. | |

| Communication protocols | IEC 61850 (Ed. 2), Modbus TCP/RTU, DNP3.0, GOOSE, MMS |

| Display | 320×240 pixel color LCD with intuitive menu navigation |

| Digital inputs/outputs | 16 digital inputs, 8 digital outputs (configurable as power or signalling outputs) |

| Operating temperature | -40°C to 70°C |

| Dimensions | 180 mm × 180 mm × 130 mm |

| Mounting type | Panel mount (flush or surface) |

| Protection rating | IP54 (front panel), IP20 (rear) |

| Certifications | IEC 60255, IEC 61850, CE, UL, ANSI/IEEE C37.239 |

| Response time | ≤20 ms for differential protection, ≤40 ms for overcurrent |

ABB REC650 1MRK008514-AB

Product introduction

The REC650 1MRK008514-AB is a state-of-the-art numerical transformer protection relay from ABB, specifically engineered to safeguard power transformers in utility substations, industrial plants, and renewable energy installations. As a flagship model in ABB’s Relion® series, it combines advanced protection algorithms with intelligent monitoring and communication capabilities, making it the cornerstone of modern transformer protection schemes.

Designed to address the unique challenges of transformer protection—such as differentiating internal faults from external disturbances or inrush currents—the REC650 integrates a comprehensive suite of protection functions. Its differential protection, the most critical feature, uses advanced restraint logic to reliably detect faults within the transformer while ignoring harmless transient events like energization inrush. This ensures selective tripping, minimizing downtime and preventing unnecessary damage to expensive transformer assets.

Beyond protection, the REC650 acts as a smart sensor hub, collecting real-time data on current, voltage, temperature, and gas levels (via Buchholz relay integration). This data is transmitted via IEC 61850 to substation automation systems, enabling condition-based maintenance and enhancing overall grid visibility. Whether protecting distribution transformers in urban networks or large power transformers in industrial complexes, the REC650 delivers unmatched reliability and performance.

Core advantages and technical highlights

Advanced differential protection

The REC650’s differential protection uses a dual-slope restraint characteristic to distinguish internal faults from external overloads or inrush currents. Unlike basic transformer relays, it employs harmonic blocking and adaptive restraint to avoid false trips during transformer energization—a common issue where inrush currents can exceed 10× rated current. For example, when a 100 MVA power transformer is energized, the REC650 analyzes the current waveform’s harmonic content, recognizing the 2nd harmonic dominance of inrush and withholding the trip signal, while instantly responding to a genuine internal short circuit.

Digital substation integration

With full IEC 61850 Ed. 2 compliance and GOOSE messaging, the REC650 seamlessly integrates into digital substations, eliminating the need for traditional hardwired interconnections. This reduces installation costs by up to 50% and enables real-time data exchange with other intelligent devices (e.g., bay controllers, SCADA systems). In a smart grid, GOOSE messages allow the relay to share trip signals with adjacent relays in milliseconds, enabling zone interlocking and enhancing system stability.

Comprehensive condition monitoring

The REC650’s thermal overload protection uses a dynamic model that calculates winding temperature based on real-time current and ambient conditions, accounting for thermal memory (i.e., accumulated heat). This prevents transformer damage during prolonged overloads, such as those caused by peak industrial demand. Additionally, integration with Buchholz relays provides early warning of incipient faults (e.g., insulation degradation) by monitoring gas accumulation in oil-immersed transformers, allowing maintenance teams to address issues before they escalate to catastrophic failures.

Rugged design for extreme environments

Rated to operate from -40°C to 70°C with IP54 front-panel protection, the REC650 thrives in harsh conditions—from arctic substations to desert solar farms. Its immunity to electromagnetic interference (EMI) ensures reliable operation near high-voltage equipment, while vibration resistance (up to 5 g) makes it suitable for mobile applications like traction substations. This durability reduces maintenance requirements in remote locations, where access is limited.

Typical application scenarios

Utility substation transformer protection

In a 220 kV substation supplying a city’s power grid, the REC650 protects a 200 MVA power transformer. During a lightning strike causing an external fault on the high-voltage side, the relay’s differential protection correctly restrains, avoiding a false trip. When a winding short circuit occurs internally, the differential element operates within 20 ms, tripping the associated circuit breakers to isolate the transformer, preventing oil fires and minimizing damage to the grid.

Industrial plant transformer

A large chemical plant uses a 50 MVA transformer to supply its production lines. The REC650’s thermal overload protection monitors winding temperature during peak production, where loads exceed rated current by 20%. The relay issues an alarm when temperature approaches safe limits, prompting operators to reduce non-critical loads. If a phase-to-earth fault develops in the transformer’s secondary winding, the restricted earth fault function trips the transformer within 30 ms, preventing acid pump failures and avoiding a costly production shutdown.

Renewable energy transformer

In a 100 MW wind farm, the REC650 protects the collector transformer that steps up generator voltage to grid levels. Its voltage protection detects grid unbalances during storm conditions, triggering a controlled shutdown of wind turbines to prevent damage. The relay’s IEC 61850 communication sends real-time transformer status to the wind farm SCADA, allowing operators to optimize maintenance schedules based on actual load cycles and fault history.

ABB REC650 1MRK008514-AB

Related model recommendations

ABB REX521GHHPSH51G

A feeder protection relay that complements the REC650 in substation automation. While the REC650 protects the transformer itself, the REX521 guards the feeders connected to the transformer’s low-voltage side, creating a coordinated protection scheme. For example, in an industrial substation, the REC650 handles transformer faults, while the REX521 protects outgoing feeders to motors and switchgear, ensuring selective tripping.

ABB RED521 1MRK002003-BA

A line protection relay used alongside the REC650 in transmission networks. The RED521 protects the high-voltage lines connecting transformers, while the REC650 protects the transformers themselves. Together, they form a complete protection system for substation feeder-transformer combinations.

ABB CMU800

A condition monitoring unit that integrates with the REC650 to enhance transformer diagnostics. It measures dissolved gas in oil, moisture levels, and partial discharges, sending data to the REC650 for analysis. This combination enables predictive maintenance, extending transformer lifespan.

ABB SPACOM S400

A communication gateway for legacy systems, allowing the REC650’s IEC 61850 data to be translated to older protocols (e.g., SCADA RTU) in retrofitted substations.

Installation, commissioning and maintenance instructions

Installation: Mount the REC650 in a control panel with adequate ventilation, ensuring 200 mm clearance around the unit. Connect current transformers (CTs) for primary and secondary windings, ensuring correct polarity for differential protection. Wire voltage transformers (VTs) to the voltage inputs, and interface with Buchholz relays via digital inputs. Use shielded Ethernet cable for IEC 61850 communication, grounding shields at both ends.

Commissioning: Use ABB’s PCM600 software to configure protection settings, including differential restraint slopes, inrush blocking parameters, and trip delays. Perform primary injection tests to verify differential protection operation—simulate internal and external faults to confirm correct restraint and tripping. Validate GOOSE message exchange with other substation devices to ensure coordinated protection.

Maintenance: Conduct quarterly visual inspections for loose connections and dust. Annually, verify protection settings via PCM600 and test digital inputs/outputs. Calibrate current/voltage measurements every 2 years using a precision test set. Update firmware periodically to access new features and security patches. For oil-immersed transformers, check Buchholz relay communication monthly to ensure gas alarm functionality.

Service and guarantee commitment

The REC650 is backed by a 7-year warranty from installation, covering manufacturing defects and performance failures. ABB’s global technical support provides 24/7 remote diagnostics, with on-site service available within 48 hours in major regions. Extended service contracts include annual preventive maintenance, firmware updates, and access to ABB’s Transformer Protection Expert program for advanced training. This commitment ensures the REC650 remains a reliable asset throughout its 20-year design lifespan.