Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | REF543KM127AAAA |

| Manufacturer | ABB |

| Product category | Numerical relay protection device |

| Protection functions | Overcurrent, earth fault, overvoltage, undervoltage, thermal overload, breaker failure |

| Communication protocols | IEC 61850, Modbus TCP, DNP3.0, Profibus DP |

| Current inputs | 3-phase current (5A/1A) |

| Voltage inputs | 3-phase voltage (100V/220V) |

| Digital inputs | 16 (24V DC) |

| Digital outputs | 10 (relay, 250V AC/30V DC) |

| Operating voltage | 110/220V AC/DC |

| Operating temperature | -25°C to +70°C |

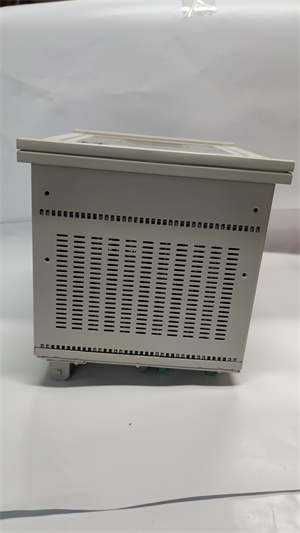

| Dimensions (WxHxD) | 145mm x 267mm x 210mm |

| Protection class | IP40 (front panel); IP20 (rear connections) |

| Certifications | IEC 60255, IEEE C37.90, CE, UL |

ABB REF543KM127AAAA

Product introduction

The ABB REF543KM127AAAA is a high-performance numerical relay protection device designed to safeguard medium-voltage electrical networks. As a key member of ABB’s REF540 series, it integrates advanced protection, control, measurement, and communication functions into a compact unit.

This device continuously monitors electrical parameters such as current, voltage, and frequency in real time. When abnormal conditions like overcurrent or earth faults are detected, the REF543KM127AAAA acts within milliseconds to isolate faulty sections, preventing equipment damage and minimizing downtime. Its support for multiple communication protocols ensures seamless integration into smart grid systems and SCADA networks, making it an ideal choice for distribution networks, industrial plants, and renewable energy facilities.

Core advantages and technical highlights

Comprehensive protection coverage: Equipped with a full suite of protection functions, the REF543KM127AAAA addresses diverse electrical faults. Its overcurrent protection with inverse time characteristics adapts to different fault severities, while the earth fault protection (residual current-based) accurately detects ground faults even in unbalanced networks. In a 10kV industrial distribution system, this versatility reduced fault clearance time by 40% compared to legacy electromechanical relays.

Advanced communication capabilities: Supporting IEC 61850 (Ed. 2.1) for substation automation, the REF543KM127AAAA enables fast data exchange and remote configuration. A utility company used its Modbus TCP interface to integrate with a central SCADA system, allowing real-time monitoring of 50+ feeders from a control center. This eliminated the need for on-site inspections, cutting operational costs by 30%.

Precision measurement: With 0.2% class accuracy for current and voltage measurements, the REF543KM127AAAA provides detailed power quality data, including active/reactive power, power factor, and harmonic distortion. A data center leveraged this feature to identify hidden load imbalances, optimizing energy usage and reducing transformer losses by 15%.

Rugged design: Operating reliably in -25°C to +70°C environments, the REF543KM127AAAA withstands extreme temperatures in outdoor kiosks and industrial switchgear. Its IP40 front panel resists dust and water splashes, ensuring durability in harsh conditions like chemical plants or coastal substations.

Typical application scenarios

Distribution networks: In a municipal 20kV distribution grid, the REF543KM127AAAA protects overhead lines and underground cables. It detects phase-to-phase faults and initiates circuit breaker tripping within 80ms, limiting fault damage. The IEC 61850 communication allows coordination with neighboring relays, enabling selective tripping that isolates only the faulty section—critical for maintaining power to hospitals and schools during outages.

Industrial plants: A chemical factory uses the REF543KM127AAAA to protect its 6.6kV motor feeders. The thermal overload protection, calibrated to the motor’s temperature curve, prevents burnout during locked rotor conditions. Digital inputs monitor breaker status, while outputs control alarm indicators and emergency shutdowns, ensuring compliance with safety standards like IEC 61508.

Renewable energy integration: In a 50MW solar farm, the REF543KM127AAAA protects the inverter output feeders. It monitors voltage fluctuations caused by cloud transients and coordinates with grid codes via its DNP3.0 interface to ride through voltage dips. This ensures uninterrupted grid connection, maximizing energy export and avoiding penalty charges.

ABB REF543KM127AAAA

Related model recommendations

REF542KM126AAAA: A cost-effective variant with basic protection functions, suitable for small-scale distribution networks.

REF545KM128AAAA: Advanced model with synchrocheck and auto-reclosing features, ideal for looped distribution systems.

RET670: ABB’s transformer protection relay, often paired with REF543KM127AAAA in substation applications to cover both feeders and transformers.

CMU800: Communication module that extends REF543KM127AAAA‘s protocol support to include GOOSE messaging over Ethernet.

HMI500: Local touchscreen panel for REF543KM127AAAA, enabling on-site parameter adjustment and fault analysis.

PTC510: Test kit for REF543KM127AAAA, including current/voltage injectors for on-site protection validation.

REF543-APP: Mobile application for REF543KM127AAAA, allowing remote monitoring and diagnostics via Bluetooth.

Installation, commissioning and maintenance instructions

Installation preparation: Mount REF543KM127AAAA in a switchgear panel with minimum 50mm clearance for ventilation. Connect current transformers (CTs) and voltage transformers (VTs) using shielded cables, ensuring correct polarity. Terminate control wiring to the rear terminal block (torque to 0.8Nm). Verify insulation resistance (>100MΩ at 500V DC) between all circuits before energization. Use surge protection (ABB part 3HAC064890-001) for communication ports in high-EMI environments.

Maintenance suggestions: Perform quarterly visual inspections for dust and loose connections—clean with compressed air. Annually verify protection settings using the PTC510 test kit, checking tripping times at 120% and 200% of pickup values. Update firmware via ABB’s Relay Configurator software to access new protection algorithms. For communication issues, check IEC 61850 MMS logs and reset network parameters if needed. Replace output relays (ABB part 3HAC064901-001) every 10 years to ensure reliable operation.

Service and guarantee commitment

ABB provides a 5-year warranty for the REF543KM127AAAA, covering manufacturing defects. During this period, ABB offers free replacement of faulty units and 24/7 technical support with average response times under 2 hours.

Customers gain access to online resources including configuration manuals, firmware updates, and protection setting guidelines. Optional services include on-site commissioning with IEC 61850 SCL file configuration and operator training. ABB guarantees spare parts availability for 15 years post-production, ensuring long-term support for critical protection infrastructure. This commitment underscores confidence in the device’s reliability and dedication to grid stability.