Description

Detailed parameter table

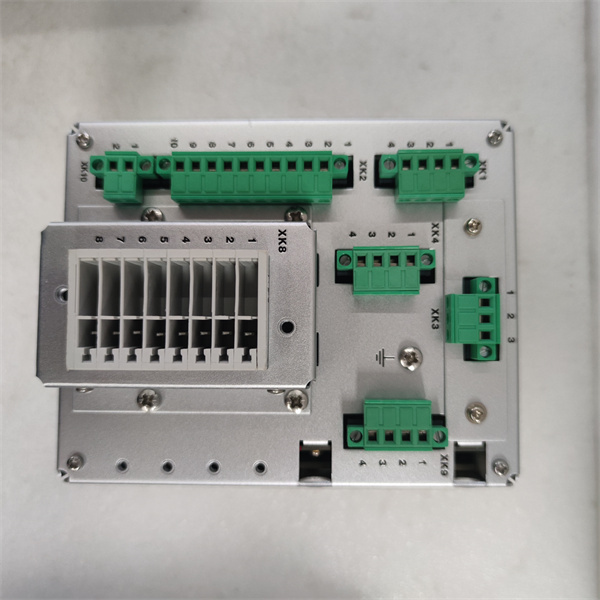

| Parameter name | Parameter value |

| Product model | REJ601 BD446NN1XG |

| Manufacturer | ABB |

| Product category | Numerical overcurrent protection relay |

| Application | Medium-voltage distribution networks (up to 36 kV) |

| Protection functions | Overcurrent, earth fault, thermal overload, breaker failure |

| Current input | 1 A or 5 A (configurable) |

| Voltage input | 100 V (phase-phase), 57.7 V (phase-earth) |

| Communication protocols | IEC 61850, Modbus TCP, DNP3.0 |

| Operating voltage | 24-250 V AC/DC |

| Power consumption | Max 15 W |

| Operating temperature | -25°C to 70°C |

| Dimensions | 145mm × 145mm × 100mm |

| Mounting type | Panel mount |

| Protection rating | IP42 (front), IP20 (rear) |

| Certifications | IEC 60255, CE, UL, ATEX |

ABB REJ601 BD446NN1XG

Product introduction

The ABB REJ601 BD446NN1XG is a advanced numerical overcurrent protection relay designed to safeguard medium-voltage distribution networks, transformers, and industrial equipment against electrical faults. As a key component in ABB’s Relion® protection portfolio, ABB REJ601 BD446NN1XG combines precise fault detection with flexible communication capabilities, ensuring rapid response to overcurrent, earth faults, and other electrical anomalies to minimize equipment damage and downtime.

ABB REJ601 BD446NN1XG features configurable protection settings, adaptive tripping characteristics, and comprehensive event logging, making it suitable for diverse applications from utility distribution grids to industrial plant substations. Its support for modern communication protocols like IEC 61850 enables seamless integration with SCADA systems and digital substation architectures, while its robust design ensures reliable operation in harsh environments. Whether deployed alongside analog input modules like the ABB DSCA114 57510001-AA or coordinating with safety modules such as the UNC4672AV1, ABB REJ601 BD446NN1XG serves as a critical safeguard, enhancing the resilience of electrical systems.

Core advantages and technical highlights

Adaptive protection algorithms: ABB REJ601 BD446NN1XG incorporates advanced algorithms that distinguish between transient overloads (e.g., motor starting) and persistent faults, preventing unnecessary tripping while ensuring rapid response to genuine threats. In a manufacturing plant with large motor loads, this adaptability allows the relay to ignore temporary inrush currents during startup while tripping instantly for a sustained overcurrent caused by a short circuit—maximizing system availability without compromising safety.

Precise fault localization: Equipped with high-resolution current measurement (0.1% accuracy) and digital signal processing, ABB REJ601 BD446NN1XG precisely identifies fault locations within 5% of the actual distance, enabling maintenance teams to quickly isolate and repair issues. In a utility distribution network, this capability reduces outage duration by directing crews to the exact section of cable or equipment requiring attention, minimizing customer downtime.

Seamless digital integration: With native support for IEC 61850 (Edition 2) and GOOSE messaging, ABB REJ601 BD446NN1XG integrates into modern digital substations, eliminating the need for traditional hardwired interlocks. This allows for remote configuration, real-time data sharing, and coordinated protection across multiple relays—simplifying system expansion and reducing wiring costs by up to 60% compared to legacy electromechanical relays.

Comprehensive event recording: The relay logs up to 1000 fault events with time-stamping accuracy of ±1 ms, capturing pre-fault and post-fault waveforms to facilitate root cause analysis. In a chemical plant, this detailed logging helps engineers determine whether a fault was caused by equipment failure, external damage, or operational errors, enabling targeted preventive measures to avoid recurrence.

Typical application scenarios

In a 10 kV industrial substation powering a paper mill, ABB REJ601 BD446NN1XG protects the main incoming feeder and distribution transformers. It monitors phase currents via current transformers, detecting a phase-to-earth fault within 30 ms and tripping the circuit breaker to isolate the faulted section. Simultaneously, it sends an IEC 61850 GOOSE message to adjacent relays, preventing cascading trips. The relay’s event log captures the fault waveform, allowing engineers to confirm that the fault originated from a damaged cable insulation—enabling targeted repairs.

In a utility distribution network, ABB REJ601 BD446NN1XG is installed at a 20 kV ring main unit, coordinating with other relays to create a self-healing grid. When a tree contacts a distribution line, the relay detects the overcurrent, trips the local breaker, and communicates via DNP3.0 with the substation SCADA system. The SCADA system then redirects power through an alternate feeder, restoring service to 90% of customers within 2 minutes—all while the relay logs the fault details for later analysis.

ABB REJ601 BD446NN1XG

Related model recommendations

ABB DSCA114 57510001-AA: An analog input module that can monitor auxiliary parameters alongside ABB REJ601 BD446NN1XG in control systems.

ABB CI627A 3BSE017457R1: A communication module that enhances integration between ABB REJ601 BD446NN1XG and PROFIBUS-based systems.

ABB UNC4672AV1 HIEE205012R1: A safety control module that coordinates with ABB REJ601 BD446NN1XG in safety-critical electrical systems.

ABB PPD512A10-454000 3BHE040375R103E: A power distribution module that supplies reliable power to ABB REJ601 BD446NN1XG.

ABB XVC517AE10 3BHB004744R0010: An HMI that displays real-time status and fault data from ABB REJ601 BD446NN1XG.

ABB TB857: A surge protection device that shields ABB REJ601 BD446NN1XG from voltage transients in substation environments.

Installation, commissioning and maintenance instructions

Installation preparation: Mount ABB REJ601 BD446NN1XG in a panel cutout using the provided brackets, ensuring a secure fit. Connect current transformers (1 A or 5 A) to the relay’s current inputs using 2.5 mm² shielded cable, observing polarity markings. Wire voltage inputs (100 V/57.7 V) from potential transformers, and connect control outputs to circuit breaker trip coils using 1.5 mm² cable. Configure communication via Ethernet or serial port using ABB’s PCM600 software. Power the relay with 24-250 V AC/DC via a dedicated circuit protected by a 1A fuse. Use a torque screwdriver set to 1.0 Nm for terminal connections. Power off all systems during installation.

Maintenance suggestions: Inspect ABB REJ601 BD446NN1XG quarterly for loose connections, dust accumulation, and LED status (power: green, healthy: steady yellow, fault: red). Clean the front panel with a dry cloth. Verify protection settings semi-annually using PCM600 software, ensuring they match the current system configuration. Test tripping functionality annually by injecting test currents and verifying breaker operation. Update firmware annually to access the latest protection algorithms. If communication fails or self-diagnostics indicate a fault, replace the relay with an ABB-certified unit to maintain protection integrity.

Service and guarantee commitment

ABB REJ601 BD446NN1XG is backed by a 5-year warranty from installation, covering manufacturing defects and ensuring protection functions meet published standards. ABB’s protection systems technical support team provides response within 2 hours for critical issues, with remote diagnostics available 24/7 to minimize outage duration. On-site service is available within 48 hours in major regions for complex commissioning or fault analysis.

The warranty includes access to configuration software (PCM600) and firmware updates. Extended service contracts offer annual protection coordination reviews, firmware updates, and priority support, ensuring the relay maintains optimal performance throughout its 20-year design lifespan. ABB’s commitment to reliability underscores confidence in ABB REJ601 BD446NN1XG as a trusted guardian of electrical systems.