Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | REL561 1MRK002496-AC |

| Manufacturer | ABB |

| Product category | Numerical overcurrent protective relay |

| Rated voltage | 110-240 V AC/DC |

| Current input | 1 A or 5 A (selectable) |

| Frequency range | 50/60 Hz (automatic detection) |

| Protection functions | Overcurrent, earth fault, short circuit, thermal overload |

| Communication protocols | IEC 61850, Modbus RTU, DNP3.0 |

| Operating temperature | -25°C to 70°C |

| Dimensions | 144 mm × 144 mm × 100 mm |

| Mounting type | Panel mount (flush or surface) |

| Protection rating | IP54 (front panel), IP20 (rear) |

| Certifications | IEC 60255, IEC 61850, CE, UL |

| Response time | ≤50 ms (for short circuit faults) |

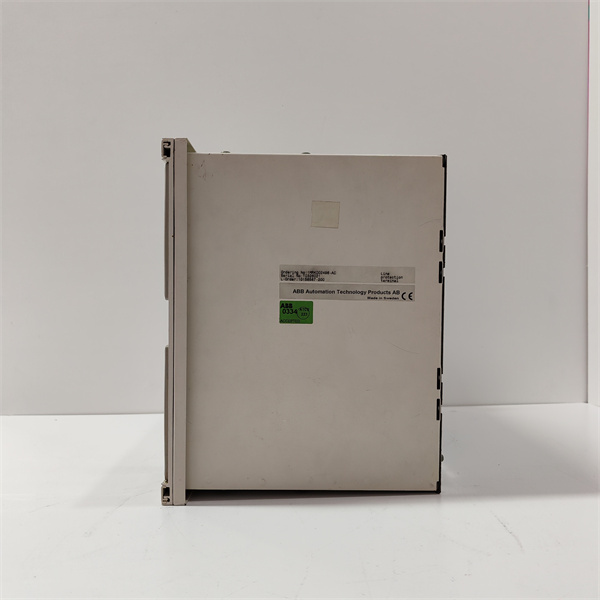

ABB REL561 1MRK002496-AC

Product introduction

The REL561 1MRK002496-AC is a high-performance numerical overcurrent protective relay from ABB, designed to safeguard medium-voltage power distribution networks and industrial electrical systems. As a key member of ABB’s Relion® product family, REL561 1MRK002496-AC combines advanced protection algorithms with flexible communication capabilities, making it suitable for applications ranging from utility substations to factory power grids.

Engineered for precision and reliability, REL561 1MRK002496-AC provides comprehensive protection against overcurrent, earth faults, and short circuits, ensuring rapid fault detection and isolation to minimize equipment damage and downtime. Its numerical design allows for easy configuration of protection settings via software, while support for modern communication protocols enables seamless integration with SCADA systems and digital substation architectures. Whether deployed in renewable energy plants, industrial facilities, or commercial buildings, REL561 1MRK002496-AC serves as a critical line of defense, enhancing the safety and efficiency of power distribution systems.

Core advantages and technical highlights

Advanced protection algorithms: REL561 1MRK002496-AC features adaptive overcurrent protection with inverse time characteristics, allowing it to adjust tripping speed based on fault severity. This ensures selective tripping—isolating only the faulty section of the network while maintaining power to other areas. For example, in a manufacturing plant’s distribution system, a minor overload on a conveyor motor triggers a delayed trip to avoid unnecessary downtime, while a catastrophic short circuit in a transformer results in an instantaneous shutdown to prevent equipment destruction.

Seamless digital integration: With native support for IEC 61850, the global standard for substation communication, REL561 1MRK002496-AC enables plug-and-play integration into digital substations. This protocol support allows real-time data exchange (including fault records, status updates, and measurement values) with SCADA systems and other intelligent electronic devices (IEDs), eliminating the need for proprietary communication links. In a solar power plant, this integration lets operators monitor relay status and power flow data from a central control room, facilitating predictive maintenance and system optimization.

Flexible configuration and monitoring: REL561 1MRK002496-AC can be fully configured via ABB’s PCM600 software, allowing engineers to customize protection settings (such as pickup currents and time delays) to match specific system requirements. The relay also includes a built-in event recorder that logs up to 500 fault events with time-stamping accuracy of ±1 ms, simplifying post-fault analysis. In a utility substation, this capability helps identify recurring fault patterns, enabling targeted infrastructure improvements to reduce outage frequency.

Robust design for harsh environments: With an operating temperature range of -25°C to 70°C and an IP54-rated front panel, REL561 1MRK002496-AC withstands extreme weather conditions and industrial contaminants. Its immunity to electromagnetic interference (EMI) ensures reliable operation in environments with high-voltage equipment or heavy machinery, such as steel mills or chemical plants. This ruggedness reduces the need for protective enclosures, lowering installation costs while maintaining performance.

Typical application scenarios

In a municipal water treatment plant, REL561 1MRK002496-AC protects the 10 kV distribution network feeding critical pumps and treatment systems. The relay monitors current flow in each feeder, using its earth fault protection to detect leaks in underground cables—preventing electrical hazards and ensuring uninterrupted water supply. Its IEC 61850 communication allows integration with the plant’s SCADA system, enabling remote monitoring of relay status and automatic generation of fault reports. During a sudden overload caused by a pump motor failure, REL561 1MRK002496-AC trips selectively, isolating the faulty feeder while keeping other treatment processes operational.

In a food processing facility, REL561 1MRK002496-AC safeguards the 400 V distribution system powering refrigeration units, mixers, and packaging machinery. The relay’s thermal overload protection prevents motor damage in conveyor systems, while its short circuit protection shields transformers from catastrophic failure. The IP54 rating ensures the relay remains operational in washdown areas, where periodic cleaning with high-pressure water is required. Integration with Modbus RTU allows the facility’s PLC to log energy consumption data via the relay, supporting energy efficiency initiatives.

ABB REL561 1MRK002496-AC

Related model recommendations

ABB REL670 1MRK005211-BD: A feeder protection relay with expanded functionality, suitable for complex substation applications alongside REL561 1MRK002496-AC.

ABB SPACOM S200: A communication gateway that enhances REL561 1MRK002496-AC’s connectivity to legacy SCADA systems.

ABB TB857: A surge protection device installed upstream of REL561 1MRK002496-AC to shield against voltage transients.

ABB 3BHB003688R0101: A power module that provides stable 24 V DC power to REL561 1MRK002496-AC in control cabinets.

ABB PCM600: Configuration software used to program and monitor REL561 1MRK002496-AC.

ABB CT600: Current transformers that provide accurate current signals to REL561 1MRK002496-AC for protection calculations.

Installation, commissioning and maintenance instructions

Installation preparation: Mount REL561 1MRK002496-AC on a panel using the provided screws, ensuring the front panel is accessible for operation and viewing. Connect current transformers (CTs) to the relay’s current inputs, ensuring correct polarity (phase A to input A, etc.). Wire the 110-240 V AC/DC power supply using 1 mm² cable, protected by a 1 A fuse. For communication, connect Ethernet or serial cables to the appropriate ports, using shielded cable with shields grounded at both ends. Power off all associated equipment during installation, and use a torque screwdriver set to 1.5 Nm for panel mounting and 0.5 Nm for terminal connections.

Maintenance suggestions: Inspect REL561 1MRK002496-AC quarterly for loose connections, dust buildup, and LED status (power: green, trip: red, alarm: yellow). Clean the front panel with a dry cloth; avoid using liquids. Verify protection settings semi-annually using PCM600 software to ensure they remain aligned with system requirements. Test trip functionality annually by injecting test currents via a relay test set, verifying that tripping occurs within the specified time limits. Check communication links monthly to ensure data is being transmitted correctly to SCADA systems. If the relay fails self-tests, contact ABB technical support before attempting repairs—use only ABB-certified replacement parts.

Service and guarantee commitment

REL561 1MRK002496-AC is backed by a 5-year warranty from the date of installation, covering manufacturing defects and ensuring compliance with published performance standards. ABB’s technical support team provides 24/7 response for critical issues, with specialized relay engineers available to assist with configuration and fault analysis. On-site commissioning services are available to ensure optimal setup and integration with existing systems.

The warranty includes free access to software updates, technical documentation, and firmware upgrades for the relay’s lifetime. Extended service contracts offer annual preventive maintenance, including calibration checks and functional testing, to maximize reliability in mission-critical applications. ABB’s commitment to excellence underscores confidence in REL561 1MRK002496-AC as a durable and trustworthy protective device for power systems.