Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | REM610C55HCNN02 |

| Manufacturer | ABB |

| Product category | Protection and control relay for medium – voltage systems |

| Rated voltage | 57.7 – 120V for auxiliary supply, suitable for connection to different voltage levels in medium – voltage setups |

| Rated current | 1A or 5A (selectable), adaptable to various current – carrying capacities in the power system |

| Protection functions | Over – current protection (instantaneous, time – graded), earth – fault protection, distance protection, and under/over – voltage protection |

| Communication interfaces | Modbus RTU, IEC 61850 (both support seamless integration with modern substation automation systems) |

| Operating temperature range | – 25°C to + 70°C, capable of withstanding harsh environmental conditions in power plants and substations |

| Mounting type | DIN – rail mountable, facilitating easy installation in standard electrical enclosures |

| Dimensions (approx.) | 144 mm x 144 mm x 125mm (W x H x D), compact design for space – constrained installations |

| Weight | Approximately 1.2 kg |

REM610C55HCNN02

Product introduction

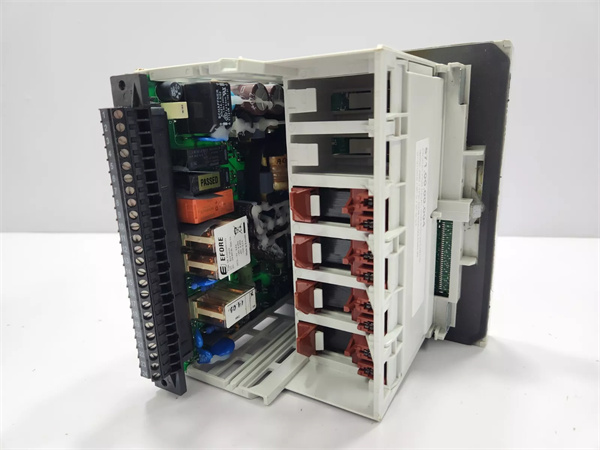

The ABB REM610C55HCNN02 is a highly advanced protection and control relay designed specifically for medium – voltage power systems. With ABB’s long – standing reputation in the power and automation industry, this relay is engineered to meet the stringent requirements of reliable power system operation.

Its primary role is to safeguard electrical equipment and ensure the stability of medium – voltage networks. By continuously monitoring electrical parameters such as current, voltage, and power, the REM610C55HCNN02 can quickly detect abnormal conditions and take appropriate protective actions. It also serves as a control interface, enabling operators to remotely manage and configure various functions within the power system, making it an integral part of modern substation automation.

Core advantages and technical highlights

Comprehensive protection functions

The REM610C55HCNN02 offers an extensive range of protection features. Its over – current protection, including both instantaneous and time – graded elements, can effectively respond to short – circuit faults. In a medium – voltage distribution network, if a sudden short – circuit occurs due to a cable insulation breakdown, the instantaneous over – current protection can trip the circuit breaker within milliseconds, preventing damage to equipment and minimizing power outages. The earth – fault protection is crucial for detecting and isolating ground faults, ensuring the safety of personnel and equipment. Distance protection, on the other hand, accurately measures the impedance between the relay and the fault location, allowing for selective tripping in long – distance transmission lines.

Advanced communication capabilities

Equipped with Modbus RTU and IEC 61850 communication interfaces, the relay enables seamless integration with other devices in a substation automation system. The Modbus RTU interface, a widely – used industrial communication protocol, allows for easy connection to PLCs, HMIs, and other intelligent devices. This enables real – time monitoring and control of the relay’s functions, such as setting protection parameters and receiving fault alarms. The IEC 61850 interface, which is specifically designed for substation automation, provides high – speed, reliable data transfer, making it suitable for large – scale power systems with complex monitoring and control requirements.

High – quality construction and environmental adaptability

Housed in a rugged enclosure, the REM610C55HCNN02 is built to withstand harsh environmental conditions. The operating temperature range of – 25°C to + 70°C makes it suitable for use in various climates, whether it’s a cold substation in a mountainous region or a hot and humid power plant in a tropical area. The DIN – rail mountable design not only simplifies installation but also ensures a secure and stable connection. The relay’s compact dimensions make it an ideal choice for installations where space is limited, such as in small – scale substations or retrofitting projects.

Typical application scenarios

Power generation plants

In a thermal power generation plant, the ABB REM610C55HCNN02 can be used to protect and control the medium – voltage side of the generator step – up transformers. It monitors the current and voltage during the start – up, normal operation, and shutdown of the generators. For example, if there is an over – voltage condition during the generator’s excitation process, the relay can quickly detect it and take corrective actions, such as adjusting the excitation system or tripping the circuit breaker to protect the transformer and other connected equipment.

Medium – voltage distribution networks

In a city’s medium – voltage distribution network, the REM610C55HCNN02 is deployed at key nodes, such as distribution substations and feeder circuits. It protects against faults in the overhead lines and underground cables. When a fault occurs in a feeder line, the relay can accurately identify the fault location using its distance protection function and isolate only the affected section, minimizing the impact on other customers. This helps to improve the reliability of power supply to residential, commercial, and industrial users.

Industrial facilities

Large industrial facilities, such as steel mills and chemical plants, often have their own medium – voltage power distribution systems. The REM610C55HCNN02 can be used to protect and control the motors, transformers, and other electrical equipment within these facilities. For instance, in a steel mill, the relay can protect the large – capacity motors used in the rolling mills. If there is an over – current or earth – fault in the motor circuit, the relay can quickly disconnect the motor from the power supply, preventing damage to the motor and ensuring the continuity of the production process.

Related model recommendations

ABB REF542plus: Another advanced protection and control relay from ABB, suitable for applications where more complex protection algorithms are required. It offers additional features such as differential protection for transformers and motors, making it a good choice for high – value assets that need enhanced protection.

ABB REC610: A cost – effective alternative to the REM610C55HCNN02, with a slightly reduced set of features. It still provides basic protection functions like over – current and earth – fault protection, making it suitable for small – to – medium – sized power systems or applications where budget constraints are a concern.

ABB RTU500: A remote terminal unit that can work in tandem with the REM610C55HCNN02. The RTU500 can collect and transmit data from various field devices, and the REM610C55HCNN02 can use this data for more accurate protection and control decisions. This combination is useful in large – scale power systems with widespread monitoring requirements.

ABB VD4 circuit breaker: As a medium – voltage circuit breaker, the VD4 can be controlled by the REM610C55HCNN02. When the relay detects a fault, it can send a tripping signal to the VD4 circuit breaker to isolate the faulty section of the power system. This integration ensures a coordinated and reliable protection scheme.

REM610C55HCNN02

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the ABB REM610C55HCNN02, ensure that the DIN – rail is securely installed in a clean, dry, and well – ventilated electrical enclosure. The enclosure should be free from excessive dust, moisture, and strong electromagnetic fields. When handling the relay, use anti – static wristbands to prevent electrostatic discharge from damaging the sensitive electronic components. Verify that the auxiliary power supply voltage available at the installation site falls within the relay’s specified range of 57.7 – 120V. Prepare the necessary wiring tools, such as wire strippers, crimping tools, and torque wrenches, and ensure that the wires used for connections are of the appropriate gauge to handle the rated current.

Maintenance suggestions

For regular maintenance, periodically check the status of the relay using its built – in diagnostic functions. The relay may have LEDs or a display panel that indicates its operating status, such as normal operation, fault detection, or communication errors. Visually inspect the connections for any signs of looseness, corrosion, or overheating. Clean the relay and its connectors regularly to remove dust and debris that could affect the electrical performance. In case of a suspected malfunction, first, disconnect the power supply to ensure safety. Then, use ABB’s dedicated software tools to perform detailed diagnostic tests, such as checking the accuracy of the protection functions and the integrity of the communication interfaces. Keep spare REM610C55HCNN02 relays in stock to minimize downtime in case of a failure.

Service and guarantee commitment

ABB offers a comprehensive quality assurance program for the REM610C55HCNN02 relay. The company stands behind the reliability and performance of the product, with a standard warranty period. ABB’s global service network is available to provide after – sales support. In case of any issues, experienced service engineers can offer both on – site and remote assistance. They can help with troubleshooting, installation guidance, and system integration support. ABB also provides regular software updates to enhance the relay’s functionality, compatibility with new devices, and security features. Additionally, detailed product documentation and training resources are available to help users make the most of the relay in their power system applications.