Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | RMIO-11C |

| Manufacturer | ABB |

| Product Category | Relay and Motor Interface Module (for ABB ACS800 series drives) |

| Compatible Drives | ACS800-01, ACS800-04, ACS800-07, ACS800-10 (0.75 kW to 560 kW) |

| Input/Output Configuration | 6 digital inputs, 2 analog inputs, 2 digital outputs, 1 relay output |

| Digital Input Type | 24 V DC (sinking) |

| Analog Input Range | 0-20 mA, 4-20 mA, 0-10 V DC (configurable per channel) |

| Digital Output Type | 24 V DC (0.5 A max) |

| Relay Output Rating | 250 V AC/30 V DC, 5 A |

| Communication | Internal drive bus (for ACS800) |

| Power Supply | 24 V DC ±10% (from drive or external source) |

| Power Consumption | ≤ 3 W |

| Operating Temperature | -10°C to +50°C |

| Dimensions (W×H×D) | 100 mm × 150 mm × 80 mm |

| Mounting Method | Direct mounting on ACS800 drive control board |

| Compliance | IEC 61800-5-1, CE, UL 508C |

| Diagnostic Features | LED indicators for power, input/output status, drive communication |

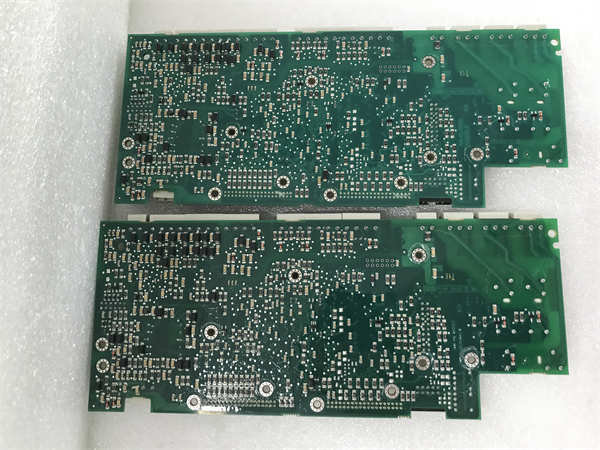

ABB RMIO-11C

Product Introduction

The RMIO-11C is a compact relay and motor interface module from ABB, specifically designed to extend the I/O capabilities of ACS800 series variable frequency drives (VFDs). It serves as a bridge between the drive and external control devices, enabling seamless integration of sensors, switches, and actuators in motor control systems. By providing 6 digital inputs, 2 analog inputs, 2 digital outputs, and 1 relay output, this module simplifies the connection of start/stop commands, speed references, status feedback, and alarm signals—critical for applications ranging from pumps and fans to conveyors and mixers.

As a native ACS800 component, the RMIO-11C communicates directly with the drive via the internal bus, ensuring low-latency signal transmission and eliminating the need for external communication adapters. Its rugged design, with operation from -10°C to +50°C and immunity to electrical noise, makes it suitable for industrial environments with harsh conditions. Whether used to control a water pump based on flow sensor inputs or to trigger an alarm when a conveyor motor overloads, the RMIO-11C enhances the flexibility and functionality of ACS800 drives, enabling precise and reliable motor control.

Core Advantages and Technical Highlights

Seamless drive integration

The RMIO-11C is engineered to work natively with ACS800 drives, eliminating compatibility issues and reducing setup time. In a factory with multiple ACS800-driven motors, this integration allows the drive to process signals from the module within 5 ms—critical for applications like high-speed conveyor synchronization, where even small delays can cause product jams.

Flexible I/O configuration

With configurable analog inputs (0-20 mA, 4-20 mA, 0-10 V) and versatile digital I/O, the module adapts to diverse control needs. For a fan system in a data center, this flexibility enables:

Digital inputs to receive start/stop commands from a PLC and fire safety signals

Analog inputs to accept temperature sensor data (4-20 mA) for speed regulation

Relay output to trigger an alarm horn if fan speed drops below setpoint

This eliminates the need for external signal converters, simplifying wiring and reducing costs.

Compact and rugged design

The module’s small form factor (100 mm × 150 mm × 80 mm) and direct mounting on the ACS800 drive save cabinet space, while its industrial-grade construction resists vibration and electrical interference. In a workshop with heavy machinery, the RMIO-11C reliably detects limit switch signals (digital input) to prevent overtravel of a CNC machine’s spindle—ensuring operator safety and equipment protection.

Typical Application Scenarios

In a municipal water treatment plant’s pump system:

RMIO-11C modules are installed on ACS800 drives controlling booster pumps.

Digital inputs receive start/stop commands from a PLC and level switch signals (high/low water in reservoirs).

Analog inputs monitor flow rate (4-20 mA from flow meters) and pressure (0-10 V from transducers) in the pipeline.

The relay output activates a bypass valve if pump pressure exceeds safe limits, preventing pipe damage.

Digital outputs send pump run/fault status back to the PLC for SCADA visualization.

In a warehouse conveyor system:

The module connects an ACS800 drive (controlling conveyor motors) to photoelectric sensors and a PLC.

Digital inputs detect package presence (sensor signals) and emergency stop commands.

Analog input receives a speed reference (4-20 mA) from the PLC, adjusting conveyor speed based on package volume.

Digital outputs trigger upstream/downstream conveyor interlocks, ensuring synchronized material flow.

LED indicators on the RMIO-11C simplify troubleshooting during maintenance (e.g., identifying a faulty sensor input).

ABB RMIO-11C

Related Model Recommendations

RMIO-02C: Advanced variant with additional communication ports (e.g., RS-485) for remote monitoring.

ACS800-07-04A1-3: ACS800 drive model optimized for use with RMIO-11C in 1.5 kW applications.

DI810: 8-channel digital input extension module for systems needing more inputs than RMIO-11C provides.

AO810: 4-channel analog output module for expanding the drive’s output capabilities.

3BSE028149R1: Terminal block kit for secure wiring of field devices to RMIO-11C.

ACS-CP-D: Drive control panel for configuring RMIO-11C parameters (input/output functions, scaling).

Installation, Commissioning and Maintenance Instructions

Installation preparation

Mount the RMIO-11C directly on the ACS800 drive’s control board using the provided screws, ensuring the connector engages fully with the drive’s internal bus. Connect 24 V DC power (from the drive’s auxiliary output or an external supply) to the module’s power terminals, verifying correct polarity. Wire field devices to the terminal block: use shielded cable for analog signals (twisted-pair) and 0.5-1.5 mm² wire for digital signals. Ground cable shields at both ends to reduce electrical noise.

Commissioning steps

Power on the ACS800 drive and use the ACS-CP-D control panel or Drive composer software to configure the RMIO-11C:

Assign digital input functions (e.g., “Start” to DI1, “Emergency Stop” to DI2).

Set analog input ranges (4-20 mA or 0-10 V) and scaling (e.g., 4 mA = 0 m³/h, 20 mA = 100 m³/h for flow rate).

Define digital output and relay functions (e.g., “Run Status” to DO1, “Overload Alarm” to relay).

Test all signals by simulating inputs (e.g., closing a switch for DI1) and verifying the drive responds correctly (e.g., starting the motor). Check that outputs activate as expected (e.g., relay energizes during a fault).

Maintenance suggestions

Inspect the RMIO-11C quarterly for loose connections, damaged wires, or corrosion on terminals. Clean the module with compressed air to remove dust, avoiding contact with internal components. Test input/output functionality annually by:

Applying a known analog signal (e.g., 12 mA) and verifying the drive reads 50% of full scale.

Triggering digital inputs and confirming the corresponding LED illuminates.

Checking that outputs activate when the drive is in specific states (e.g., DO1 lights when the motor runs).

Replace the module if LEDs fail to illuminate, inputs/outputs are unresponsive, or communication with the drive is lost (after checking wiring). Use only ABB-approved replacements to maintain drive compatibility.

Service and Guarantee Commitment

The RMIO-11C is backed by a 2-year warranty, covering defects in materials and workmanship under normal operating conditions. ABB’s drive technical support team provides guidance on configuration, troubleshooting, and integration with ACS800 drives, including access to wiring diagrams and parameter guides.

Customers receive support for programming input/output functions via Drive composer software, with application examples for pumps, conveyors, and fans. ABB ensures rapid availability of replacement modules through global distribution centers, minimizing downtime for critical motor control systems. Training on ACS800 drive systems (including RMIO-11C) is available to help technicians optimize performance and maintenance.