Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | SA801F |

| Manufacturer | ABB |

| Product category | Safety automation controller (for industrial safety systems) |

| Safety integrity level | SIL 3 (per IEC 61508) |

| Input channels | 16 safety-related digital inputs (24 V DC) |

| Output channels | 8 safety-related relay outputs |

| Communication protocols | Safety over EtherCAT (FSoE), Modbus TCP/IP (for non-safety data) |

| Operating voltage | 24 V DC ±15% |

| Power consumption | ≤ 15 W |

| Operating temperature | -20°C to +60°C |

| Dimensions (W×H×D) | 120 mm × 180 mm × 100 mm |

| Mounting method | DIN rail mounting (35 mm standard) |

| Protection rating | IP20 |

| Diagnostic coverage | ≥ 99% (for critical faults) |

| Certification | IEC 61508, EN ISO 13849-1 (PL e), CE, UL 1998 |

ABB SA801F

Product introduction

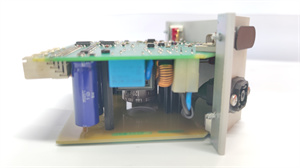

The ABB SA801F is a high-integrity safety automation controller designed to monitor and control safety-critical processes in industrial environments. As a core component of ABB’s safety system portfolio, it ensures compliance with global safety standards by preventing hazardous conditions through reliable fault detection and protective actions.

Equipped with 16 safety digital inputs and 8 safety relay outputs, the SA801F interfaces with emergency stops, light curtains, and interlock switches, translating their signals into immediate safety responses—such as stopping machinery or isolating hazardous zones. Its SIL 3 certification confirms its ability to handle the most demanding safety applications, where failure could lead to human injury or equipment damage.

In automation systems, the SA801F operates independently of standard control systems, providing a dedicated safety layer. Its integration with FSoE protocol enables seamless communication with other safety components, while Modbus TCP/IP allows non-safety data sharing with HMI or SCADA systems—balancing strict safety requirements with operational visibility.

Core advantages and technical highlights

Dual-core safety architecture

The SA801F features redundant dual-core processors that execute safety logic in lockstep, continuously cross-checking results to detect internal faults. In automotive assembly lines, this architecture ensures that a light curtain breach triggers an immediate stop signal, even if one core experiences a transient error—eliminating single points of failure.

Flexible safety configuration

Using ABB’s Safety Builder software, the SA801F supports customizable safety logic without requiring low-level programming. For example, in a packaging machine, engineers can configure a “handguard interlock + emergency stop” logic chain with adjustable time delays, ensuring compliance with machinery safety standards (EN ISO 13850) without complex coding.

Seamless integration

The SA801F communicates via FSoE, enabling it to connect with ABB’s S200 Safety I/O modules and third-party safety devices on a single network. In a chemical plant, this allows the controller to coordinate safety actions across multiple process units—such as shutting down both a reactor and its feed pump if a pressure sensor exceeds the safe threshold—reducing wiring complexity by 40% compared to hardwired safety systems.

Typical application scenarios

In a pharmaceutical manufacturing facility, the SA801F safeguards sterile processing areas. It monitors door interlocks on cleanrooms, ensuring that machinery inside stops operating if a door is opened during production. The controller also connects to gas leak detectors; upon detecting a hazardous substance, it triggers exhaust fans and isolates the affected zone—preventing contamination and protecting workers.

In a steel mill’s hot rolling section, the SA801F oversees worker safety around high-temperature equipment. It integrates with thermal scanners and emergency stop buttons along the rolling line. If a scanner detects a worker entering a restricted area, the SA801F immediately halts the roller motors and activates warning lights—responding in under 100 ms to minimize burn risks.

In logistics warehouses with automated cranes, the SA801F prevents collisions by monitoring crane position sensors and aisle entry interlocks. If two cranes approach the same aisle, the controller prioritizes their movement or stops one entirely, ensuring compliance with occupational safety regulations while maintaining operational efficiency.

ABB SA801F

Related model recommendations

SA802F: A 2-channel expansion of SA801F with 32 inputs/16 outputs, ideal for larger safety systems like automotive paint shops with multiple hazard zones.

S200-IO-16D: Safety I/O module that extends SA801F’s input capacity, adding 16 digital inputs for applications requiring more sensor connections (e.g., food processing lines with multiple guards).

SA801F-PROFIBUS: Variant of SA801F with Profibus DP safety protocol, compatible with legacy systems in oil refineries upgrading to SIL 3 compliance.

CS3100: ABB’s safety PLC that pairs with SA801F in complex safety loops, handling advanced logic for nuclear power plant auxiliary systems.

S800L Safety Relay: Standalone relay that works with SA801F for simple safety functions (e.g., emergency stops), serving as a cost-effective 补充 in distributed setups.

SA801F-ETH: Enhanced version of SA801F with redundant Ethernet ports, ensuring uninterrupted communication in mission-critical facilities like semiconductor fabs.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the SA801F on a grounded 35 mm DIN rail in a dust-free enclosure with ambient temperature < 60°C. Use shielded twisted-pair cables (0.5 mm²) for safety I/O connections, grounding shields at both ends. Verify 24 V DC supply with a multimeter before wiring—install a dedicated 2 A fuse to prevent voltage spikes. Keep safety wiring separate from power cables to avoid electromagnetic interference.

Maintenance suggestions: Inspect the SA801F monthly by checking the “SAFE” LED (solid green indicates normal operation). Test safety functions quarterly using ABB’s Test Tool software, simulating input faults (e.g., shorting an emergency stop circuit) to confirm output activation. Backup configuration files to a secure drive biweekly. Replace relay outputs every 100,000 operations or if contact resistance exceeds 100 mΩ—use only ABB-certified relays to maintain SIL 3 integrity. If communication faults occur, check FSoE network settings and cable terminations before replacing the controller.

Service and guarantee commitment

The ABB SA801F comes with a 5-year warranty covering manufacturing defects, including free replacement of faulty components. ABB’s safety-certified engineers provide on-site commissioning support to ensure compliance with SIL 3 requirements, including validation of safety logic and fault tolerance.

Customers gain access to 24/7 technical support via ABB’s global safety hotline, with response times under 4 hours for critical issues. Online resources include safety manual updates, configuration templates, and training videos for certified personnel. ABB guarantees spare part availability for 10 years post-purchase, ensuring long-term system maintainability. This commitment reflects ABB’s confidence in the SA801F’s reliability as a safety-critical component in industrial environments.