Description

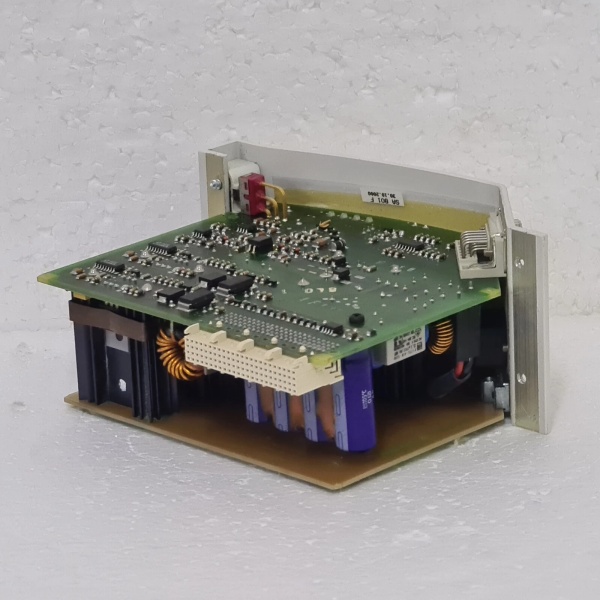

ABB SA801F

-

Model Number: SA801F -

Manufacturer: ABB -

Product Type: Safety Digital Input Module -

Number of Channels: 8 (individually isolated) -

Input Type: Dry contact (relay, 24V DC), Solid-state (transistor, 24V DC) -

Input Voltage: 24V DC nominal (18-30V DC range) -

Isolation Voltage: 2500VAC (channel-to-channel, channel-to-bus) -

SIL Certification: SIL 3 (IEC 61508, Hardware Fault Tolerance ≥2) -

Response Time: <20 ms (input change to controller update) -

Operating Temperature: -40°C to +70°C -

Humidity Range: 5% to 95% non-condensing -

Power Supply: 24V DC (from S800 I/O rack backplane) -

Power Consumption: 1.5W (typical, all channels active) -

Diagnostics: Channel short/open circuit, power monitoring, communication heartbeat -

Hot Swap Support: Yes (plug-and-play replacement without system shutdown) -

Dimensions: 25mm x 128mm x 115mm (width x height x depth, fits S800 I/O slot)

ABB SA801F

thresholds are breached.