Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | SDCS-COM-81 3ADT314900R1002 |

| Manufacturer | ABB |

| Product category | Communication interface module for ACS880 drives |

| Supported protocols | PROFINET IO, Ethernet/IP, Modbus TCP/IP |

| Data transfer rate | 10/100 Mbps (auto-negotiation) |

| Interface type | 2 x RJ45 Ethernet ports (for network redundancy) |

| Operating voltage | 24 V DC ±10% (from drive control board) |

| Power consumption | ≤ 3 W |

| Operating temperature | -40°C to +70°C |

| Dimensions (W×H×D) | 120 mm × 80 mm × 40 mm |

| Installation method | Plug-in module for ACS880 drive control unit |

| Protection class | IP20 (when installed in drive enclosure) |

| Diagnostic features | Link status LEDs, error code display, built-in self-test |

| Compliance | IEC 61800-5-1, CE, UL, PROFINET Certified |

| Compatible systems | ABB ACS880 industrial drives, PLCs, SCADA systems, AO810 analog modules |

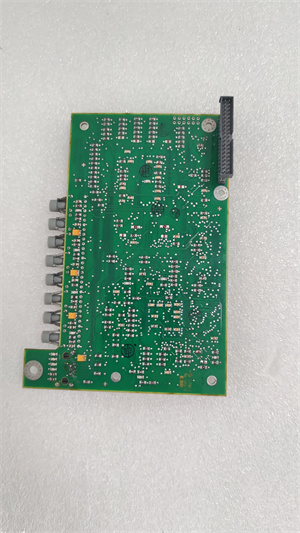

ABB SDCS-COM-81 3ADT314900R1002

Product introduction

The SDCS-COM-81 3ADT314900R1002 is a high-performance communication interface module from ABB, specifically designed to enable advanced network connectivity for ACS880 industrial drives. As a key component in drive automation systems, it serves as the bridge between the drive and industrial networks, facilitating real-time data exchange for monitoring, control, and configuration.

Supporting multiple industrial Ethernet protocols—PROFINET IO, Ethernet/IP, and Modbus TCP/IP—SDCS-COM-81 3ADT314900R1002 offers flexible integration into diverse automation architectures. Its dual Ethernet ports enable network redundancy, ensuring uninterrupted communication in critical applications. Whether connecting drives to PLCs for coordinated control or linking to SCADA systems for centralized monitoring, SDCS-COM-81 3ADT314900R1002 ensures reliable data transmission, enhancing the efficiency and visibility of drive operations in industrial environments.

Core advantages and technical highlights

Multi-protocol support

SDCS-COM-81 3ADT314900R1002 eliminates the need for protocol-specific modules by supporting PROFINET IO, Ethernet/IP, and Modbus TCP/IP. In a automotive manufacturing plant with mixed-brand PLCs, this versatility allows a single ACS880 drive to communicate with a Siemens PLC via PROFINET and a Rockwell HMI via Ethernet/IP—simplifying network design and reducing hardware costs.

Redundant network capability

Dual Ethernet ports with automatic failover ensure continuous communication, even if one network path fails. In a wastewater treatment plant, where drive downtime could lead to overflow incidents, this redundancy guarantees that control signals from the PLC to the pump drive remain intact, maintaining critical operations.

Seamless drive integration

Designed exclusively for ACS880 drives, SDCS-COM-81 3ADT314900R1002 integrates seamlessly with the drive’s control system, providing access to 1000+ drive parameters and real-time data points. This deep integration allows engineers to monitor motor current, torque, and temperature via the network, enabling predictive maintenance that reduces unplanned downtime by up to 30% compared to basic communication modules.

Typical application scenarios

In a large-scale food processing facility, SDCS-COM-81 3ADT314900R1002 enables centralized control of multiple ACS880 drives across the production line:

Connects via PROFINET to a central PLC, receiving speed setpoints for conveyor drives based on product demand.

Transmits real-time drive data (current, temperature, fault codes) to an HMI via Ethernet/IP, providing operators with instant visibility.

Supports Modbus TCP/IP communication with a energy management system, tracking power consumption for each drive.

The module works alongside AO810 analog output modules in the PLC system, where analog signals from the PLC are converted to network commands by SDCS-COM-81 3ADT314900R1002, ensuring precise speed control of mixers and pumps critical to recipe consistency.

In a mining conveyor system, SDCS-COM-81 3ADT314900R1002 facilitates coordinated operation of multiple ACS880 drives:

Enables synchronized speed control via PROFINET, preventing product jams between conveyor sections.

Transmits fault data to a SCADA system within 100 ms, triggering automatic backup drive activation.

Supports remote configuration via Ethernet/IP, allowing engineers to adjust drive parameters without accessing the hazardous mining environment.

ABB SDCS-COM-81 3ADT314900R1002

Related model recommendations

ACS880-01-04A1-3: Compact ACS880 drive compatible with SDCS-COM-81 3ADT314900R1002 for small to medium applications.

SDCS-COM-61: Modbus RTU communication module that complements SDCS-COM-81 3ADT314900R1002 in hybrid network environments.

AO810: Analog output module that works with SDCS-COM-81 3ADT314900R1002 when analog control signals need conversion to network commands.

CI840A: Profibus module that pairs with SDCS-COM-81 3ADT314900R1002 in systems requiring both Ethernet and Profibus connectivity.

ACS880-07-0460A-7: High-power ACS880 drive ideal for use with SDCS-COM-81 3ADT314900R1002 in heavy-industry applications.

SDCS-PIN-51: I/O extension module that connects to drives via SDCS-COM-81 3ADT314900R1002 for additional digital signals.

3HAC031683-001: ABB HMI panel that communicates with drives through SDCS-COM-81 3ADT314900R1002 for local monitoring.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing SDCS-COM-81 3ADT314900R1002, power off the ACS880 drive and disconnect all power sources. Locate the communication slot on the drive’s control unit, ensuring the module alignment pins match the slot guides. Insert the module firmly until it clicks into place, securing with the locking screw (torque to 0.5 Nm). Connect Ethernet cables (Cat 5e or higher) to both RJ45 ports, using shielded cables grounded at both ends to minimize EMI. Configure network parameters (IP address, subnet mask) via the drive’s local control panel or ABB Drive composer software before powering on.

Maintenance suggestions

Daily checks of SDCS-COM-81 3ADT314900R1002 involve verifying green link/activity LEDs on both Ethernet ports; flashing amber LEDs indicate network issues. Monitor drive communication status via the PLC or SCADA system, checking for error codes related to network timeouts. Inspect Ethernet connectors quarterly for corrosion or damage, cleaning with isopropyl alcohol if needed. If communication failures persist, reset the module via the drive’s control panel—replace SDCS-COM-81 3ADT314900R1002 with an ABB-approved spare if faults continue, ensuring the replacement is configured with identical network settings.

Service and guarantee commitment

The SDCS-COM-81 3ADT314900R1002 is backed by a 2-year warranty, covering defects in materials and workmanship under normal operating conditions. ABB’s drive technical support team provides 24/7 assistance for network configuration, including guidance on integrating with PLCs, SCADA systems, and modules like the AO810.

Customers receive access to detailed protocol implementation guides and commissioning checklists for SDCS-COM-81 3ADT314900R1002. ABB offers on-site training for network engineers, ensuring optimal setup of redundant networks and protocol-specific features. With global distribution centers, replacement modules are available for rapid delivery, minimizing downtime in critical drive communication links. Trust SDCS-COM-81 3ADT314900R1002 for reliable connectivity in ACS880 drive systems, backed by ABB’s expertise in industrial drive automation.