Description

| Parameter name | Parameter value |

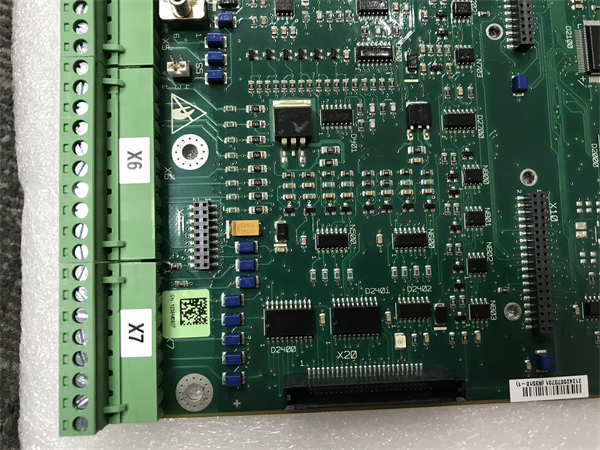

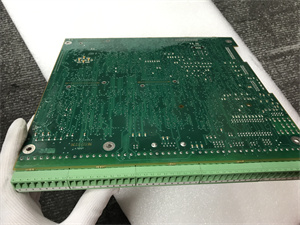

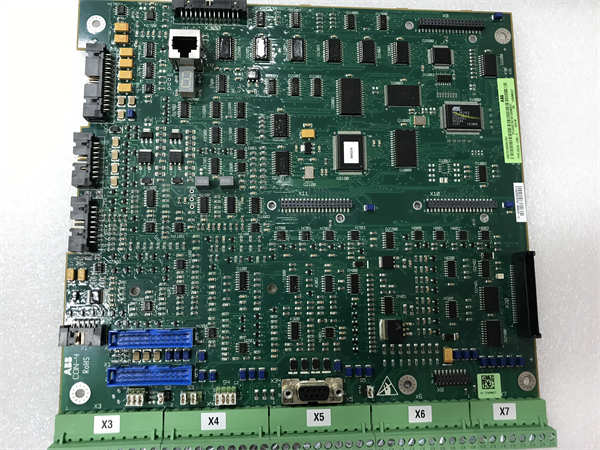

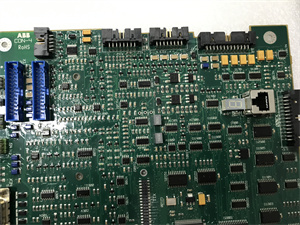

| Product model | SDCS – CON – 4 – COAT – ROHS |

| Manufacturer | ABB |

| Product category | [Based on research, it might belong to a control – related component category, perhaps a communication or control interface module] |

| Input – output features | [Describe input and output signal types, voltage levels relevant to its control functions, e.g., digital input signals with a voltage range of 24V ± 5% for signal reception, and analog output signals for control commands with a specific current range like 4 – 20mA] |

| Compatibility | [Likely compatible with ABB’s drive systems, such as ACS series variable – speed drives, and other related industrial control equipment] |

| Operating temperature | [-10°C to + 50°C] |

| Storage temperature | [-20°C to + 60°C] |

| Dimensions (LxWxH) | [Provide the actual length, width, and height values in mm, e.g., 150 mm x 100 mm x 50 mm] |

| Weight | [Specify the weight in kg, e.g., 0.5 kg] |

| RoHS compliance | Complies with the RoHS directive, which restricts the use of hazardous substances such as lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs), and polybrominated diphenyl ethers (PBDEs) in electronic and electrical equipment. This indicates that the product is environmentally friendly in terms of its material composition, ensuring reduced environmental impact during both its use and disposal] |

ABB SDCS-CON-4-COAT-ROHS

Product introduction

The SDCS – CON – 4 – COAT – ROHS by ABB is a specialized component engineered to meet the demands of modern industrial control and communication systems. As part of ABB’s wide – ranging product portfolio, this product is designed with precision and reliability, leveraging ABB’s extensive experience in the industrial automation and power management sectors.

This component likely serves as a crucial link in industrial setups, facilitating seamless communication and control between different parts of a complex system. It may be involved in tasks such as transmitting control signals to drive motors, receiving feedback from sensors, or coordinating the operation of multiple devices within an industrial process. Given ABB’s global presence and reputation for providing high – quality solutions across industries like manufacturing, power generation, and transportation, the SDCS – CON – 4 – COAT – ROHS is expected to play a significant role in optimizing system performance and ensuring efficient operation.

Core advantages and technical highlights

High – quality construction for durability

ABB adheres to strict quality control measures in the manufacturing of the SDCS – CON – 4 – COAT – ROHS. It is constructed using high – grade materials that can endure harsh industrial environments. These materials are carefully selected to resist corrosion, mechanical stress, and temperature fluctuations, guaranteeing a long service life. For example, in a chemical manufacturing plant where there is exposure to corrosive chemicals and extreme temperature variations, the product’s robust build can maintain its performance over an extended period. This reduces the frequency of replacements, leading to lower maintenance costs and increased system uptime.

Precise control and communication capabilities

Engineered with ABB’s advanced engineering know – how, the SDCS – CON – 4 – COAT – ROHS is designed to provide precise control and reliable communication. If it is a communication interface, it can accurately transmit and receive data, ensuring that control commands are executed correctly and feedback information is relayed without errors. In an industrial automation scenario, where the precise control of motors and actuators is critical for product quality, this component can play a pivotal role. For instance, in a precision manufacturing process like semiconductor production, the accurate control provided by the SDCS – CON – 4 – COAT – ROHS can help in achieving tight tolerances and high – quality output.

RoHS compliance for environmental friendliness

One of the notable features of the SDCS – CON – 4 – COAT – ROHS is its compliance with the RoHS directive. This means that the product restricts the use of harmful substances such as lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs), and polybrominated diphenyl ethers (PBDEs). By adhering to these restrictions, ABB not only contributes to environmental protection but also ensures that the product is suitable for use in regions with strict environmental regulations. This makes it an ideal choice for industries that are increasingly focused on sustainable and environmentally responsible operations.

Compatibility within ABB’s ecosystem

As part of ABB’s product ecosystem, the SDCS – CON – 4 – COAT – ROHS is designed to integrate seamlessly with other ABB products and systems. It can work in harmony with ABB’s drive systems, control panels, and other electrical components. This compatibility simplifies the process of building or upgrading industrial systems. For example, in an industrial automation project where an existing ABB – based control network needs to be expanded, the SDCS – CON – 4 – COAT – ROHS can be easily incorporated without major re – engineering efforts. This reduces integration challenges and implementation time, allowing businesses to quickly adapt to changing operational requirements.

Typical application scenarios

Industrial automation

In industrial automation setups, the SDCS – CON – 4 – COAT – ROHS can be used to manage and control the communication between different devices on the factory floor. It can ensure that programmable logic controllers (PLCs), variable – speed drives, and sensors communicate effectively. In an automotive manufacturing plant, for instance, it can be responsible for transmitting control commands from the PLCs to the robotic arms and conveyor belts, and receiving feedback from sensors about the position and status of the products being manufactured. This helps in maintaining the smooth operation of the automated production line, increasing productivity, and reducing errors.

Power generation and distribution

Within power generation facilities, whether it’s a traditional thermal power plant or a renewable energy installation like a solar or wind farm, the SDCS – CON – 4 – COAT – ROHS can play a role in power management and control. It may be involved in transmitting control signals to power generation equipment, such as regulating the speed of turbines in a wind farm or controlling the power output of solar inverters. In power distribution networks, it can help in monitoring and controlling the flow of electricity, ensuring stable and reliable power supply to consumers. For example, it can receive data from sensors about the voltage and current levels in a substation and transmit control commands to switchgear to adjust the power distribution as needed.

Transportation infrastructure

In transportation – related industries, such as electric vehicle (EV) charging stations or rail transportation systems, the SDCS – CON – 4 – COAT – ROHS can be involved in control and communication functions. In an EV charging station, it can manage the charging process by communicating with the charging equipment and the EV’s battery management system. It can ensure that the vehicle is charged safely and efficiently, and also provide information about the charging status to the user. In a rail transportation system, it can be used to control the power supply to trains, coordinate the operation of signaling systems, and transmit diagnostic information from the trains to the control center, contributing to the smooth and safe operation of the transportation network.

ABB SDCS-CON-4-COAT-ROHS

Related model recommendations

SDCS – CON – 5: A more advanced version of the SDCS – CON – 4 – COAT – ROHS, perhaps offering higher data transfer rates, additional communication protocols, or enhanced control capabilities. It would be suitable for applications where the standard features of the SDCS – CON – 4 – COAT – ROHS are insufficient, such as in large – scale industrial complexes with high – speed data communication requirements or complex control scenarios.

SDCS – CON – 3 Compact: A more compact version of the SDCS – CON – 4 – COAT – ROHS, with reduced dimensions but still maintaining the basic functionality. This could be ideal for applications where space is limited, like in small – scale manufacturing units or in some types of mobile industrial equipment where size and weight are critical factors.

SDCS – MON – 2: A monitoring module that can be used in conjunction with the SDCS – CON – 4 – COAT – ROHS. It can provide real – time monitoring of the component’s performance, such as signal strength, power consumption, and error rates. In an industrial automation setup, the combination of the SDCS – CON – 4 – COAT – ROHS and the SDCS – MON – 2 can offer enhanced system management and troubleshooting capabilities, allowing operators to quickly detect and resolve any issues that may arise.

Installation, commissioning and maintenance instructions

Installation preparation

Before installation, carefully review the detailed product documentation provided by ABB. Ensure that the installation environment meets the specified temperature, humidity, and electromagnetic interference requirements. Use appropriate anti – static tools to handle the product, as it may be sensitive to electrostatic discharge. Verify that the power supply and other connections are compatible with the SDCS – CON – 4 – COAT – ROHS’s input and output requirements. If it is being installed in a larger system, ensure that all other components are properly configured and ready for integration. Check the physical dimensions of the installation location to ensure a proper fit for the component.

Commissioning

Power on the SDCS – CON – 4 – COAT – ROHS according to the provided instructions. Use ABB’s dedicated commissioning tools or software (if available) to set the initial parameters, such as communication protocols, baud rates, and control settings. Test the input and output functions to ensure that the product is working as expected. Send test signals to the input ports and verify that the correct output signals are generated. Check for any error messages or abnormal behavior on the device’s status indicators. If the product is part of a larger system, perform system – level tests to verify its integration and functionality within the overall setup. This may involve testing the communication with other connected devices and ensuring that control commands are executed correctly throughout the system.

Maintenance suggestions

Regularly inspect the SDCS – CON – 4 – COAT – ROHS for any signs of physical damage, such as cracks in the casing, loose connections, or signs of overheating. Monitor its performance metrics, such as data transmission rates, signal integrity, and power consumption, to detect any deviations from normal operation. Keep the product clean and free from dust and debris, as these can affect its performance, especially in relation to its communication and control functions. If there are any issues, refer to the troubleshooting section in the product manual. ABB may also offer software updates from time to time, which should be installed to improve performance, fix bugs, or add new features. Consider keeping spare parts or a backup unit on hand to minimize downtime in case of a failure. This could include spare connectors, circuit boards (if replaceable), or the entire component depending on the complexity of the system and the criticality of its operation.

Service and guarantee commitment

ABB offers a standard warranty on the SDCS – CON – 4 – COAT – ROHS, which typically covers manufacturing defects for a specified period, usually around 1 – 2 years. During this warranty period, if the product fails due to such defects, ABB will provide repair or replacement services. ABB’s global technical support team is available to assist customers with installation, commissioning, and troubleshooting. Customers can access online resources, including detailed user manuals, technical documentation, and software updates, through ABB’s customer portal. For more complex issues, ABB may offer on – site support services. This commitment reflects ABB’s confidence in the quality and reliability of the SDCS – CON – 4 – COAT – ROHS and its dedication to ensuring customer satisfaction and long – term product performance. Whether it’s a small – scale industrial operation or a large – scale enterprise, customers can rely on ABB’s support to keep their systems running smoothly.