Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | SDCS-PIN-51 |

| Manufacturer | ABB |

| Product Category | I/O adapter module for ABB ACS800 and ACS880 variable frequency drives (VFDs) |

| Input/Output Type | Analog and digital signals (configurable) |

| Analog Inputs | 2 channels (4-20 mA, 0-10 V DC; configurable range) |

| Digital Inputs | 4 channels (24 V DC, sinking) |

| Digital Outputs | 2 channels (24 V DC, 0.5 A max; relay contact option) |

| Isolation | 2.5 kV AC (field to drive) |

| Operating Voltage | 24 V DC ±10% (from drive or external supply) |

| Power Consumption | ≤ 3 W |

| Operating Temperature | -10°C to +50°C |

| Dimensions (W×H×D) | 120 mm × 80 mm × 60 mm |

| Mounting Method | Direct mounting on drive control board via connector; DIN rail optional |

| Communication | Integrated with drive’s internal bus; compatible with SDCS-COM-81 modules |

| Compliance | IEC 61800-5-1, CE, UL 508C |

| Compatible Drives | ABB ACS800 series (ACS800-04, ACS800-07), ACS880 series, ACS880-01 micro drives |

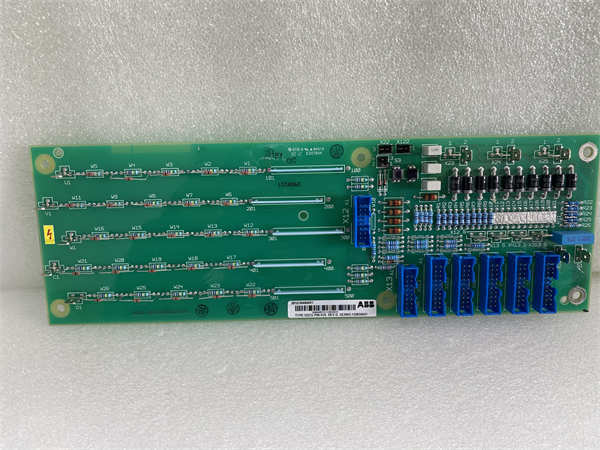

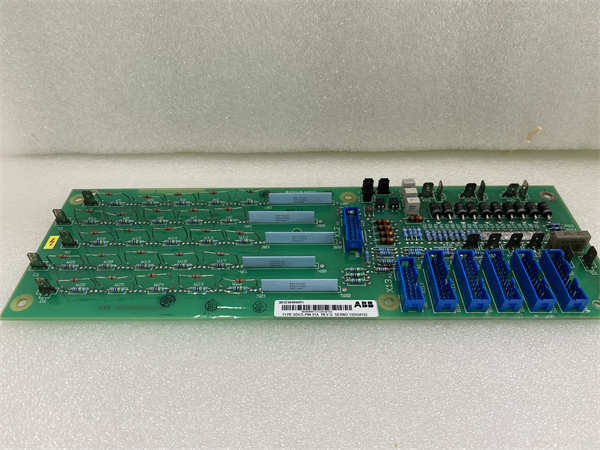

ABB SDCS-PIN-51

Product Introduction

The SDCS-PIN-51 is a compact I/O adapter module from ABB, designed to expand the input/output capabilities of ACS800 and ACS880 variable frequency drives (VFDs). It serves as a flexible interface between the drive and external control devices, enabling seamless integration with sensors, PLCs, HMIs, and other automation components in industrial motor control systems.

By adding 2 analog inputs, 4 digital inputs, and 2 digital outputs, this module enhances the drive’s ability to monitor process variables (e.g., pressure, flow) and execute control logic based on external signals. Its rugged design and 2.5 kV isolation ensure reliable operation in noisy industrial environments, while compatibility with ABB’s drive ecosystem simplifies installation and programming. Whether used in pumps, fans, conveyors, or compressors, the SDCS-PIN-51 extends the drive’s functionality, enabling precise motor control and system automation.

Core Advantages and Technical Highlights

Flexible signal configuration

The SDCS-PIN-51 allows analog inputs to be configured for 4-20 mA or 0-10 V signals, adapting to diverse sensor types. In a water pump system, this flexibility enables the module to:

Accept 4-20 mA from a pressure transducer to monitor pipeline pressure

Receive 0-10 V from a flow meter to track water flow rate

This eliminates the need for external signal converters, reducing system complexity and cost.

Enhanced drive integration

As a native ABB module, it communicates seamlessly with ACS800/ACS880 drives via the internal bus, ensuring low-latency signal transmission. In a fan control system for a data center, this integration allows the drive to adjust fan speed within 10 ms of a temperature sensor signal from the SDCS-PIN-51—critical for maintaining server room temperatures within 1°C of setpoints.

Robust industrial design

With 2.5 kV isolation and immunity to electrical noise, the module operates reliably in environments with heavy machinery or high-voltage equipment. In a factory with welding robots (which generate EMI), the SDCS-PIN-51 accurately detects emergency stop signals from a PLC, ensuring the drive shuts down the motor safely.

Typical Application Scenarios

In a wastewater treatment plant’s aeration blower system:

SDCS-PIN-51 modules are installed on ACS880 drives controlling blower motors.

Analog inputs monitor dissolved oxygen (DO) levels (4-20 mA from DO sensors) in aeration basins.

Digital inputs receive start/stop commands from a PLC and emergency stop signals from pushbuttons.

Digital outputs send blower run/fault status back to the PLC and activate alarm lights.

The drive uses DO feedback to adjust blower speed, optimizing energy use while maintaining required oxygen levels.

In a manufacturing plant’s conveyor belt system:

The module connects an ACS800 drive to photoelectric sensors (digital inputs) that detect product presence.

Analog inputs receive speed reference signals (0-10 V) from a PLC, allowing variable conveyor speeds based on production demand.

Digital outputs trigger upstream/downstream conveyors via interlock signals, ensuring synchronized material flow.

DIN rail mounting simplifies installation in the conveyor’s control cabinet, alongside other automation components.

ABB SDCS-PIN-51

Related Model Recommendations

SDCS-PIN-52: Higher-channel variant with 4 analog inputs, compatible with larger drive systems.

SDCS-COM-81: Communication adapter that pairs with SDCS-PIN-51 for Profibus DP connectivity to PLCs.

ACS880-07-04A1-3: ACS880 drive model optimized for use with SDCS-PIN-51 in 1.5 kW motor applications.

SDCS-I/O-EXT: Extension kit for SDCS-PIN-51 to add 8 more digital inputs in large systems.

3BSE028149R1: Terminal block for SDCS-PIN-51 field wiring, ensuring secure connections.

ACS-CP-D: Control panel for configuring SDCS-PIN-51 parameters via the drive’s interface.

Installation, Commissioning and Maintenance Instructions

Installation preparation

Mount the SDCS-PIN-51 on the ACS800/ACS880 drive’s control board using the provided connector, ensuring a secure fit. For remote mounting, use the optional DIN rail adapter and connect via a 10-pin cable (max length 1 m). Wire field devices to the terminal block: analog signals with shielded twisted-pair cable, digital signals with 0.5-1.5 mm² wire. Connect 24 V DC power (from the drive or external supply) to the module’s power terminal.

Commissioning steps

Power on the drive and access the SDCS-PIN-51 configuration menu via the ACS-CP-D panel or Drive composer software. Set analog input ranges (4-20 mA or 0-10 V) and assign digital input/output functions (e.g., “Start” to DI1, “Run Status” to DO1). Test signal transmission by:

Applying a 12 mA signal to an analog input and verifying the drive reads 50% of full scale

Closing a digital input contact and confirming the drive responds with the assigned action

Calibrate analog inputs if needed using a precision signal generator, though factory settings are typically accurate.

Maintenance suggestions

Inspect SDCS-PIN-51 quarterly for loose connections or damaged wires. Clean terminal blocks with compressed air to remove dust. Test input/output functionality annually by simulating signals and verifying drive response. If analog signals drift beyond ±1% of full scale or digital channels fail to trigger, replace the module—use only ABB-approved replacements to maintain drive compatibility. Update drive firmware periodically to ensure optimal module performance.

Service and Guarantee Commitment

The SDCS-PIN-51 is backed by a 2-year warranty, covering defects in materials and workmanship. ABB’s drive technical support team provides guidance on configuration, troubleshooting, and integration with ACS800/ACS880 systems.

Customers receive access to detailed wiring diagrams and parameter guides for SDCS-PIN-51, including application examples for pumps, fans, and conveyors. ABB offers training on drive I/O modules, helping technicians maximize system performance. With global distribution, replacement modules are available for rapid delivery, minimizing downtime for critical motor control systems.