Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | SDCS-PIN48-SD |

| Manufacturer | ABB |

| Product Category | I/O interface module (for ABB ACS880 and ACS6000 series drives) |

| Input/Output Configuration | 8 digital inputs, 4 digital outputs, 2 analog inputs, 1 analog output |

| Digital Input Type | 24 V DC (sinking/sourcing, configurable) |

| Digital Output Type | 24 V DC (0.5 A max), relay contacts (1 A @ 250 V AC) |

| Analog Input Range | 4-20 mA, 0-10 V DC (configurable per channel) |

| Analog Output Range | 4-20 mA (configurable) |

| Isolation | 2.5 kV AC (field to drive) |

| Operating Voltage | 24 V DC ±10% |

| Power Consumption | ≤ 5 W |

| Operating Temperature | -10°C to +50°C |

| Dimensions (W×H×D) | 140 mm × 90 mm × 70 mm |

| Mounting Method | Direct mounting on drive control panel or DIN rail (35 mm) |

| Compliance | IEC 61800-5-1, CE, UL 508C |

| Compatible Drives | ABB ACS880 industrial drives, ACS6000 medium-voltage drives, SDCS-COM-81 communication modules |

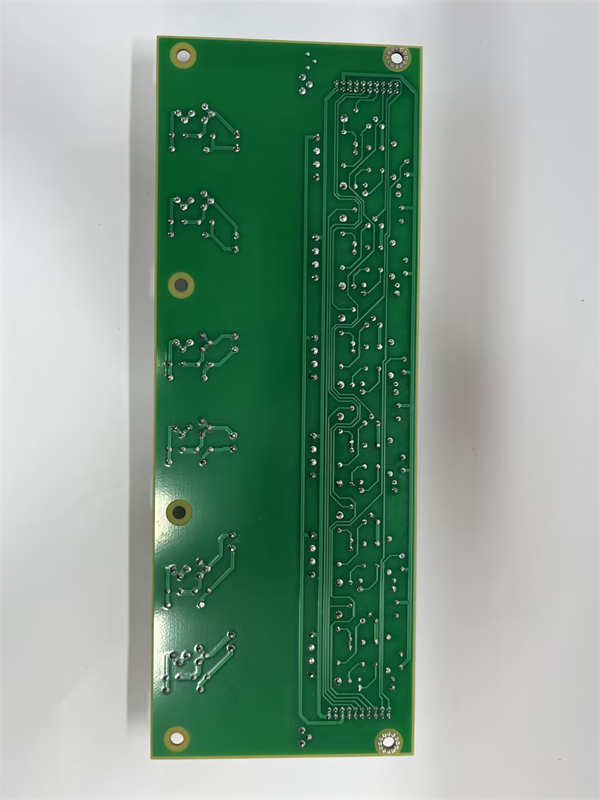

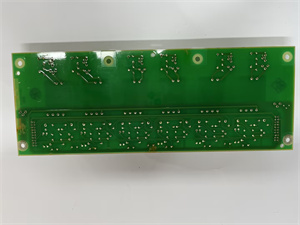

ABB SDCS-PIN48-SD

Product Introduction

The SDCS-PIN48-SD is a versatile I/O interface module from ABB, engineered to expand the connectivity of ACS880 and ACS6000 series variable frequency drives (VFDs). It serves as a bridge between the drive and field devices, enabling seamless integration with sensors, PLCs, HMIs, and control systems in industrial automation.

With a rich mix of 8 digital inputs, 4 digital outputs, 2 analog inputs, and 1 analog output, this module supports diverse control logic—from simple start/stop commands to complex process feedback loops. Its robust design includes 2.5 kV electrical isolation and immunity to electromagnetic interference (EMI), ensuring reliable operation in harsh industrial environments such as manufacturing plants, power generation facilities, and mining operations. Whether used to monitor pressure transducers, trigger alarms, or adjust motor speed via analog signals, the SDCS-PIN48-SD enhances drive functionality, enabling precise and efficient motor control.

Core Advantages and Technical Highlights

Multi-signal versatility

The module’s combination of digital and analog I/O eliminates the need for multiple single-function modules. In a pulp and paper mill’s roller drive system, for example:

- Digital inputs handle emergency stop, jog, and fault reset signals

- Analog inputs monitor roller pressure (4-20 mA) and speed feedback (0-10 V)

- Analog output adjusts a tension controller’s setpoint

- Digital outputs trigger status lamps and interlock signals to upstream equipment

This integration reduces cabinet space by 30% compared to using separate modules.

Seamless drive communication

As a native ABB component, it communicates with ACS880/ACS6000 drives via the internal high-speed bus, ensuring sub-10 ms signal latency. In a wind turbine’s pitch control system, this speed is critical: the module transmits wind speed sensor data (analog input) to the ACS880 drive, which adjusts the pitch motor within 5 ms to optimize energy capture.

Industrial-grade reliability

With 2.5 kV isolation and wide temperature tolerance, the SDCS-PIN48-SD operates reliably in noisy environments. In a steel mill’s rolling mill, where high-voltage equipment generates EMI, it accurately detects limit switch signals (digital input) to prevent overtravel of the rollers—avoiding costly downtime.

Typical Application Scenarios

In a natural gas compression station’s motor control system:

- SDCS-PIN48-SDmodules are installed on ACS880 drives controlling compressor motors.

- Digital inputs receive start/stop commands from a PLC and pressure switch signals (high/low pressure).

- Analog inputs monitor discharge pressure (4-20 mA from pressure transmitters) and motor bearing temperature (0-10 V from RTD transmitters).

- The analog output modulates a valve positioner to control gas flow, synchronized with drive speed.

- Digital outputs send run/fault status to the SCADA system and activate local alarm horns.

In a mining conveyor belt system:

- The module connects an ACS6000 drive to conveyor sensors and a PLC.

- Digital inputs detect belt misalignment switches and emergency pull cords.

- Analog inputs measure belt tension (4-20 mA) and load cells (0-10 V) to prevent overloading.

- Digital outputs activate belt cleaners and upstream feeder interlocks.

- DIN rail mounting in the conveyor’s control cabinet simplifies wiring to field devices.

ABB SDCS-PIN48-SD

Related Model Recommendations

- SDCS-PIN-51: Compact I/O module with fewer channels, compatible with smaller ACS880 drives.

- SDCS-COM-81: Profibus DP adapter that pairs with SDCS-PIN48-SDfor PLC communication.

- ACS880-07-09A7-3: ACS880 drive model optimized for use with SDCS-PIN48-SDin 4 kW applications.

- 3BSE028149R1: Terminal block kit for SDCS-PIN48-SDfield wiring.

- SDCS-FEX-41: Fiber optic extension module for remote mounting of SDCS-PIN48-SDup to 100 m from the drive.

- ACS-CP-D: Drive control panel for configuring SDCS-PIN48-SD

Installation, Commissioning and Maintenance Instructions

Installation preparation

Mount SDCS-PIN48-SD directly on the ACS880/ACS6000 drive’s control panel using the provided screws, or on a 35 mm DIN rail in the control cabinet. Connect 24 V DC power (from the drive or external supply) to the module’s terminal block. Wire field devices using shielded cable: 0.5-1.5 mm² for digital signals, twisted-pair shielded for analog signals (ground shields at both ends). Configure digital inputs as sinking or sourcing via DIP switches on the module.

Commissioning steps

Power on the drive and use ABB’s Drive composer software to configure the module:

- Assign digital input functions (e.g., DI1 = Start, DI2 = Stop).

- Set analog input ranges (4-20 mA or 0-10 V) and scaling (e.g., 4 mA = 0 psi, 20 mA = 1000 psi).

- Configure analog output scaling (e.g., 4-20 mA corresponding to 0-100% drive speed).

- Test all signals: simulate a 12 mA input to verify 50% pressure reading, trigger a digital input to confirm drive response, and check analog output accuracy with a calibrator.

Maintenance suggestions

Inspect SDCS-PIN48-SD quarterly for loose connections, damaged wires, or corrosion. Clean terminals with compressed air to remove dust. Test digital inputs/outputs annually by manually triggering signals and verifying drive/PLC response. Calibrate analog channels yearly using a precision signal generator—drift exceeding ±0.5% of full scale indicates the need for recalibration. Replace the module if channels fail or isolation tests (2.5 kV AC) fail. Use only ABB-approved replacements to maintain drive compatibility.

Service and Guarantee Commitment

The SDCS-PIN48-SD is backed by a 2-year warranty, covering defects in materials and workmanship under normal operating conditions. ABB’s drive technical support team provides 24/7 assistance for configuration, troubleshooting, and integration with ACS880/ACS6000 systems.

Customers receive access to detailed wiring diagrams, parameter lists, and application notes for SDCS-PIN48-SD, including examples for compressors, conveyors, and pumps. ABB offers on-site training for technicians on module maintenance and drive integration. With global distribution centers, replacement modules are available for rapid delivery, minimizing downtime in critical industrial processes.