Description

Detailed Parameter Table

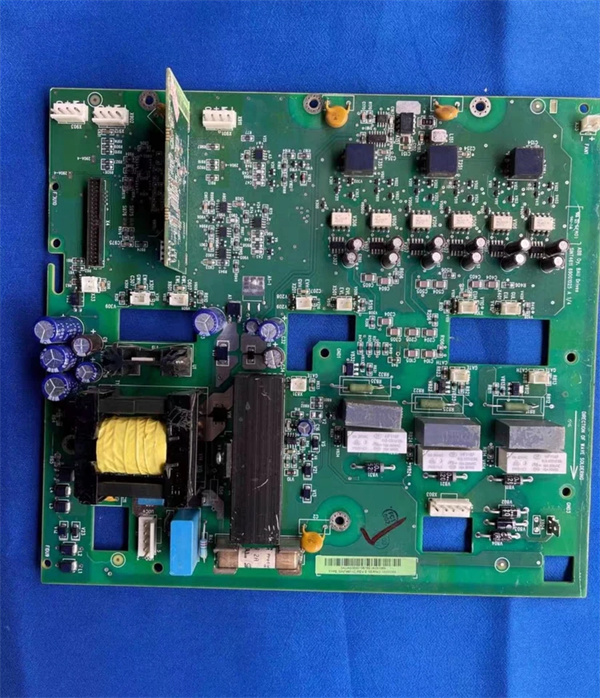

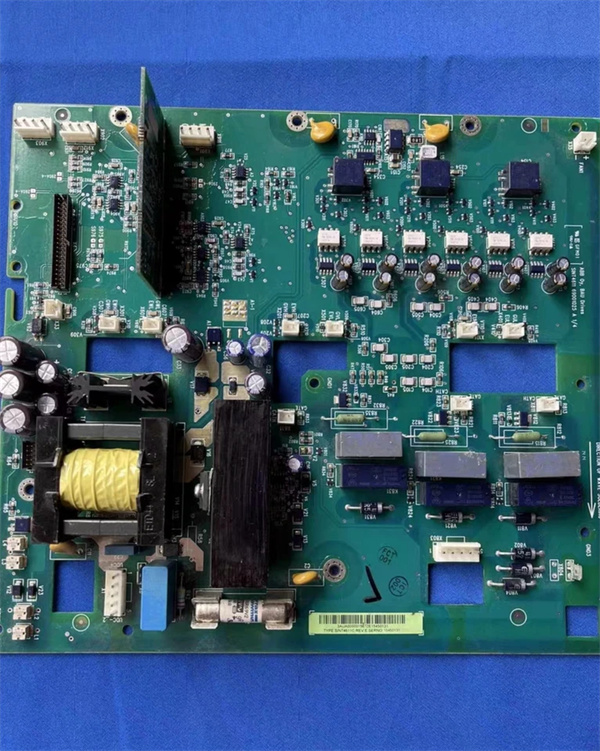

| Parameter Name | Parameter Value |

| Product Model | SINT4611C |

| Manufacturer | ABB |

| Product Category | Power supply module |

| Input Voltage Range | 100 – 240 V AC |

| Output Voltage | 24 V DC |

| Maximum Output Current | 10 A |

| Output Power | 240 W |

| Efficiency | ≥ 90% at full load |

| Ripple and Noise | ≤ 50 mV p-p |

| Protection Features | Overcurrent, overvoltage, short-circuit, overtemperature protection |

| Operating Temperature Range | -25°C to +70°C |

| Protection Class | IP20 (when installed in control cabinet) |

| Dimensions (W×H×D) | 125 mm × 120 mm × 110 mm (approx.) |

| Weight | 0.8 kg (approx.) |

| Compatibility | ABB DO524 A3 1SAP240700R0001 digital output module, DSQC652 robot I/O module |

| Mounting | DIN rail mounting (35 mm) |

| Certification | CE, UL, TÜV |

ABB SINT4611C

Product Introduction

The ABB SINT4611C is a high-efficiency power supply module designed to provide stable and reliable 24 V DC power in industrial automation systems. As a critical component in power management, it converts alternating current (AC) from the mains into direct current (DC) suitable for powering sensitive electronic devices and modules, ensuring consistent operation even in fluctuating input conditions.

This module is capable of delivering up to 10 A of current, making it ideal for powering multiple components in a control system, such as the ABB DO524 A3 1SAP240700R0001 digital output module, ABB DSQC652 robot I/O module, and other low-voltage devices. Its robust design and comprehensive protection features ensure it can withstand the harsh conditions of industrial environments, providing a secure power source for the entire automation chain.

Core Advantages and Technical Highlights

Stable Output Performance

The ABB SINT4611C delivers a precise 24 V DC output with ripple and noise as low as 50 mV p-p, ensuring clean power for sensitive electronics like the ABB DO524 A3 1SAP240700R0001 digital output module. This stability prevents signal interference and ensures accurate operation of connected devices. For example, in a robotic assembly cell, the module’s low noise output ensures that the ABB DSQC652 robot I/O module receives consistent power, maintaining reliable communication between the robot and PLC system.

Wide Input Range and High Efficiency

With an input voltage range of 100 – 240 V AC, the ABB SINT4611C can adapt to different mains voltages worldwide, making it suitable for global industrial applications. Its efficiency of ≥ 90% at full load minimizes energy loss and reduces heat generation, allowing for compact installation in control cabinets without the need for additional cooling. In a food processing plant with varying mains voltage, this flexibility ensures the ABB DO524 A3 1SAP240700R0001 and other modules receive stable power, preventing disruptions to the bottling line.

Comprehensive Protection Mechanisms

Equipped with overcurrent, overvoltage, short-circuit, and overtemperature protection, the ABB SINT4611C safeguards both itself and connected devices. If a short circuit occurs in a solenoid valve connected to the ABB DO524 A3 1SAP240700R0001, the module shuts down immediately to prevent damage to the output module and wiring. Its overtemperature protection activates if the module exceeds 70°C, ensuring safe operation even in poorly ventilated cabinets—a critical feature in high-temperature industrial environments like steel mills.

ABB SINT4611C

Typical Application Scenarios

In an automotive manufacturing control cabinet, the ABB SINT4611C serves as the primary power source for a cluster of modules, including the ABB DO524 A3 1SAP240700R0001 and ABB DSQC652. It converts 230 V AC mains power to 24 V DC, supplying the digital output module to control conveyor actuators and the robot I/O module to coordinate robotic welding arms. The module’s overcurrent protection prevents overloads when multiple actuators activate simultaneously, ensuring the entire system remains operational during peak demand. Its wide input range also accommodates voltage fluctuations from the factory’s heavy machinery, maintaining stable power to critical components.

In a pharmaceutical packaging line, the ABB SINT4611C powers a network of sensors, indicators, and the ABB DO524 A3 1SAP240700R0001 module, which controls blister pack sealers and labelers. The module’s low ripple output ensures sensors provide accurate readings of package alignment, while its reliable power delivery prevents sealers from malfunctioning—critical for maintaining product sterility. If a labeler motor draws excessive current, the power supply’s overcurrent protection triggers, shutting down the motor via the digital output module to avoid equipment damage and production delays.

In a warehouse automation system, the ABB SINT4611C supplies power to the ABB DO524 A3 1SAP240700R0001 (controlling conveyor motors) and temperature relays like the ABB TR104 (monitoring server room conditions). Its compact size allows installation in space-constrained cabinets alongside other components, while its efficiency reduces energy costs for 24/7 operations. During mains voltage dips, the module’s stable output ensures conveyors and robots continue operating without interruption, preserving order fulfillment schedules.

Related Model Recommendations

- ABB SINT4620C: A higher-power version with a 20 A output, suitable for systems with more devices than the ABB SINT4611Ccan support.

- ABB DO524 A3 1SAP240700R0001: A digital output module that relies on the ABB SINT4611Cfor stable 24 V DC power to control industrial actuators.

- ABB DSQC652: A robot I/O module that pairs with the power supply to receive reliable power for robot peripheral control.

- ABB TR104: A temperature relay that, when powered by the ABB SINT4611C, monitors thermal conditions in control cabinets or machinery.

- ABB TB820V2 3BSE013208R0001: A terminal base that organizes power connections from the ABB SINT4611Cto other modules, simplifying wiring.

- ABB SPBRC400: A busbar trunking system that distributes mains power to the ABB SINT4611Cin large-scale industrial setups.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the ABB SINT4611C, ensure the control cabinet is clean, dry, and well-ventilated. The ambient temperature should be within -25°C to +70°C, with relative humidity below 95% (non-condensing). Required tools include a screwdriver (PH2), wire strippers, and a torque wrench (set to 0.5 – 0.7 Nm). Mount the module on a 35 mm DIN rail, leaving at least 10 mm of space on all sides for airflow. Connect the input power (100 – 240 V AC) to the L, N, and PE terminals, ensuring proper grounding. Use 1.5 – 2.5 mm² wires for input and 0.5 – 1.5 mm² wires for the 24 V DC output, stripping insulation to 8 – 10 mm.

Commissioning Steps

After installation, verify all wiring connections against the module’s label and system diagram. Power on the input and check the front-panel LED: a green LED indicates normal operation, while a red LED signals a fault (e.g., overcurrent). Use a multimeter to confirm the output voltage is 24 V DC ± 0.5 V. Connect the ABB DO524 A3 1SAP240700R0001 and test its outputs to ensure they function with the new power supply. Simulate a fault (e.g., short-circuit an output) to verify the power supply shuts down and restarts correctly after the fault is cleared. For systems with the ABB DSQC652, confirm robot I/O signals transmit reliably with the new power source.

Maintenance Suggestions

For daily maintenance, inspect the ABB SINT4611C for dust buildup and clean with compressed air (low pressure). Check input/output connections quarterly to ensure tightness—loose wires can cause overheating. Monitor the module’s temperature during operation using an infrared thermometer; readings above 60°C indicate poor ventilation, requiring cabinet fan upgrades. If the red fault LED illuminates, disconnect power, identify the cause (e.g., overcurrent device), resolve it, then restart. Replace the module if faults persist despite troubleshooting. It is recommended to calibrate the output voltage annually using a precision multimeter to ensure it remains within specifications.

Service and Guarantee Commitment

The ABB SINT4611C comes with a 3-year warranty, covering defects in materials and workmanship under normal operating conditions. During the warranty period, ABB will repair or replace faulty modules free of charge. Our global technical support team is available 24/7 via phone, email, or online chat to assist with installation, troubleshooting, and technical inquiries.

We provide comprehensive online resources, including user manuals, wiring diagrams, and compatibility guides, to support efficient deployment. Optional service contracts offer on-site inspections, preventive maintenance, and priority response times, ensuring optimal performance throughout the module’s lifecycle. ABB’s commitment to quality ensures the SINT4611C delivers reliable power, keeping your industrial automation systems running smoothly.