Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | SNAT634PAC |

| Manufacturer | ABB |

| Product category | Safety network adapter (part of 800xA Safety system) |

| Communication protocols | Safety over Ethernet (SIL 3), PROFINET, Modbus TCP/IP |

| Ethernet ports | 2 x 10/100/1000 Mbps (gigabit, redundant) |

| Safety integrity level | SIL 3 (per IEC 61508) |

| Safety application | Up to 1000 safety-related signals |

| Operating temperature | -20°C to 60°C |

| Storage temperature | -40°C to 85°C |

| Humidity tolerance | 5 – 95% RH (non-condensing) |

| Mounting type | DIN rail (35mm) |

| Dimensions | 110mm (height) x 150mm (width) x 70mm (depth) |

| Certifications | TÜV, CE, UL, IECEx |

| Power supply | 24 VDC ±10%, 10 W max |

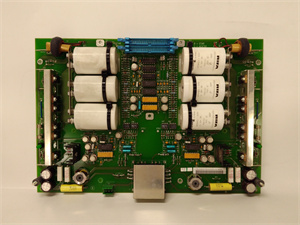

ABB SNAT634PAC

Product introduction

The ABB SNAT634PAC is a high-integrity safety network adapter, a critical component of ABB’s 800xA Safety system. It serves as a dedicated interface for transmitting safety-related data between safety controllers, I/O modules, and the broader 800xA distributed control system (DCS), ensuring secure and reliable communication in safety-critical industrial environments.

Equipped with redundant gigabit Ethernet ports and certified for SIL 3 (Safety Integrity Level 3) operation, this adapter is engineered to handle safety-related signals with zero loss or corruption, even in the event of network faults. Its support for industry-standard protocols like PROFINET and Modbus TCP/IP allows seamless integration with both safety and non-safety components of the automation system. The ABB SNAT634PAC plays a pivotal role in maintaining the integrity of safety loops, enabling rapid response to hazardous conditions and ensuring compliance with global safety standards.

Core advantages and technical highlights

SIL 3 certification: The ABB SNAT634PAC is certified to SIL 3 per IEC 61508, representing the highest level of safety integrity for industrial network devices. This certification guarantees that the adapter can detect and mitigate faults with a probability of failure on demand (PFD) low enough to meet the strictest safety requirements—essential for applications such as emergency shutdown systems (ESD) in oil refineries or interlock systems in chemical plants.

Redundant communication paths: Featuring two redundant gigabit Ethernet ports, the adapter ensures uninterrupted transmission of safety data. If one port or network path fails, the other automatically takes over within milliseconds, eliminating single points of failure. This redundancy is critical in safety-critical systems where communication downtime could delay a safety response, such as stopping a high-speed press in an automotive factory when a worker enters a hazardous zone.

Deterministic data delivery: The adapter uses specialized safety protocols over Ethernet to ensure deterministic transmission of safety signals, with latency as low as 1ms. This predictability ensures that safety commands—such as triggering an emergency stop or isolating a hazardous process—are executed without delay. In pharmaceutical manufacturing, for example, this determinism ensures that a batch reactor is shut down immediately if pressure exceeds safe limits.

Seamless safety and standard integration: By supporting both safety protocols (for SIL 3 data) and standard industrial protocols (PROFINET, Modbus TCP/IP), the ABB SNAT634PAC enables bidirectional data flow between safety controllers and the 800xA DCS. Safety-related alarms and statuses are visible in the main HMI, while non-safety process data can be shared with safety systems for context-aware decision-making. This integration eliminates the need for separate safety and standard networks, reducing complexity and cost.

Typical application scenarios

In oil and gas production platforms, the ABB SNAT634PAC connects ESD controllers to the 800xA Safety system, transmitting critical signals such as high-pressure alarms, fire detection, and gas leak alerts. Its SIL 3 certification ensures these signals are relayed without corruption, enabling the ESD system to isolate wells or shut down pumps within milliseconds. The redundant Ethernet ports prevent communication failures in harsh marine environments, where salt spray and vibration could disrupt standard network devices.

Within chemical processing plants, the adapter integrates safety interlock systems (e.g., for reactor overpressure protection) with the main DCS. It transmits safety signals from pressure transmitters and temperature sensors to the safety controller, while also relaying non-safety data (e.g., flow rates) to the DCS for process optimization. This dual functionality allows operators to monitor both safety and process conditions in a single interface, improving situational awareness during abnormal events.

In power generation facilities, the ABB SNAT634PAC links turbine protection systems to the 800xA Safety network. It handles safety signals such as overspeed detection and bearing temperature trips, ensuring the turbine is shut down safely if critical limits are exceeded. The deterministic communication ensures that these shutdown commands are executed before damage occurs, protecting both equipment and personnel.

ABB SNAT634PAC

Related model recommendations

ABB SNAT635PAC: A higher-capacity variant supporting up to 2000 safety signals, suitable for large-scale safety systems in refineries or petrochemical plants.

ABB 800xA Safety Controller: The core safety logic solver that pairs with the ABB SNAT634PAC to process safety signals and execute protective actions.

ABB CI867K01: A safety I/O module that connects field devices (e.g., emergency stop buttons) to the safety network, with data transmitted via the SNAT634PAC.

ABB CB801 3BSE042245R1: An industrial Ethernet switch that provides the network backbone for the SNAT634PAC, ensuring reliable data transmission in mixed safety/standard networks.

ABB 800xA HMI Safety View: A dedicated HMI interface that displays safety alarms and statuses relayed by the ABB SNAT634PAC, enabling operators to manage safety events.

ABB 24 VDC redundant power supply: Ensures uninterrupted power to the SNAT634PAC, with redundancy to prevent safety network failures during power outages.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB SNAT634PAC, ensure the 35mm DIN rail is securely mounted and grounded per IEC 61508 requirements. Verify the operating environment meets the temperature (-20°C to 60°C) and humidity (5-95% RH) ranges. Gather tools: torque screwdrivers (for DIN rail mounting), network cable tester, and a multimeter. Use shielded Cat6 Ethernet cables for redundant network paths, with cable lengths limited to 100m to maintain signal integrity. Ensure the 24 VDC power supply is fused at 1A and has a separate safety ground.

Commissioning steps: Mount the adapter on the DIN rail and connect redundant power supplies and Ethernet cables (one to the safety controller, one to the DCS network). Power on the module and verify the status LEDs: green for normal operation, dual green for redundant path health. Use ABB’s Safety Builder software to configure safety protocols, signal mappings, and redundancy settings. Perform a SIL verification test by simulating safety signals (e.g., triggering an emergency stop) and confirming they are received by the safety controller within the required latency (<1ms). Validate redundancy by disconnecting one Ethernet cable and ensuring signal transmission continues via the alternate path.

Maintenance suggestions: Inspect the ABB SNAT634PAC quarterly for loose connections, dust, or corrosion. Clean vents with compressed air to prevent overheating. Monitor LED indicators daily—red or flashing LEDs indicate faults (e.g., network failure, power loss) requiring immediate attention. Perform annual functional tests by simulating 10% of safety signals to verify data integrity. Back up configuration files monthly to a secure, encrypted location. For firmware updates, use ABB’s Safety Update Tool to ensure compatibility with the safety controller and compliance with SIL 3 requirements. Never use third-party software for updates, as this could invalidate safety certifications.

Service and guarantee commitment

The ABB SNAT634PAC comes with a 36-month warranty from the purchase date, covering manufacturing defects and ensuring compliance with SIL 3 specifications. ABB guarantees replacement of faulty units within 48 hours for safety-critical applications, minimizing downtime in safety loops.

Technical support includes access to ABB’s global safety engineering team, available 24/7 for critical issues. Online resources include safety manual updates, SIL verification checklists, and troubleshooting guides specific to the SNAT634PAC. Customers can utilize ABB’s certified safety service engineers for on-site commissioning and periodic safety audits. Optional extended service contracts include annual SIL revalidation, priority firmware updates, and on-site maintenance, ensuring the adapter maintains its safety integrity throughout its 15-year design lifespan.