Description

Detailed parameter table

| Parameter name | Parameter value |

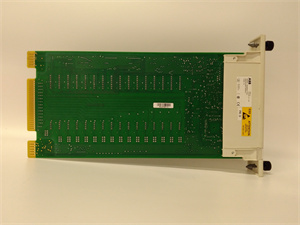

| Product model | SPASI23 |

| Manufacturer | ABB |

| Product category | High-performance analog input module |

| Number of channels | 16 |

| Input range – Thermocouple (TC) | -200 °C to +1800 °C |

| Input range – Resistance Temperature Detector (RTD) | -200 °C to +800 °C |

| Input range – Thermistor | -50 °C to +150 °C |

| Input range – Voltage | -10 V to +10 V |

| Input range – Current | -20 mA to +20 mA |

| Precision | 0.1% of full scale |

| Conversion time | 250 µs |

| Isolation | 2500 V rms |

| Power consumption | 2.5 W |

| Dimensions (LxWxH) | 73.66 mm x 360.68 mm x 269.24 mm |

| Weight | 0.771 kg |

| Mounting type | DIN rail |

| Compatibility | ABB’s AC800m control system |

ABB SPASI23

Product introduction

The SPASI23 from ABB is a meticulously designed 16-channel analog input module. It is engineered to integrate flawlessly within ABB’s advanced AC800m control system, serving as a crucial component for industrial automation processes. This module is a powerhouse when it comes to handling a diverse range of analog input signals.

SPASI23 excels in temperature measurement, adeptly processing inputs from thermocouples (TCs), resistance temperature detectors (RTDs), and thermistors. It can accurately measure voltages spanning from -10 V to +10 V and currents from -20 mA to +20 mA. In an industrial automation setup, the SPASI23 plays a pivotal role in gathering real-time data from various sensors. This data is then fed into the AC800m control system, enabling precise control and monitoring of industrial processes. Whether it’s in a manufacturing plant, a power generation facility, or a chemical processing unit, the SPASI23 ensures that the control system has access to highly accurate analog input information, which is essential for maintaining process efficiency and product quality.

Core advantages and technical highlights

High precision: The SPASI23 offers an outstanding input accuracy of 0.1% of full scale. This high level of precision is critical in applications where even the slightest deviation in measurement can lead to significant process inefficiencies or product defects. For instance, in pharmaceutical manufacturing, precise temperature and pressure measurements are essential for ensuring the quality and consistency of drugs. The SPASI23‘s accuracy enables such industries to meet strict quality control standards.

Wide input range: With its ability to handle a broad spectrum of input signals including TCs, RTDs, thermistors, voltages, and currents, the SPASI23 provides unparalleled flexibility. This versatility means that it can be used in a wide variety of industrial applications without the need for multiple specialized modules. In a single manufacturing facility, it can be used to measure the temperature of ovens (using TCs), the pressure of hydraulic systems (using voltage or current sensors), and the temperature of refrigeration units (using RTDs or thermistors).

Fast conversion time: Boasting a rapid conversion time of 250 µs, the SPASI23 is well-suited for applications where signals change rapidly. In high-speed manufacturing lines, for example, sensors may detect quick changes in product dimensions or process parameters. The SPASI23 can quickly convert these analog signals into digital data that can be processed in real-time by the control system, allowing for immediate adjustments to the manufacturing process to maintain product quality.

Galvanic isolation: The module provides 2500 V rms galvanic isolation between input and output circuits. This isolation is crucial in protecting the module and the connected control system from electrical noise and ground faults. In industrial environments, where there is a high risk of electrical interference from motors, generators, and other high-power equipment, the SPASI23‘s isolation feature ensures reliable operation and data integrity.

Typical application scenarios

In power generation plants, the SPASI23 is extensively used for monitoring and controlling power generation equipment. It can measure the temperature of turbine bearings (using TCs) to prevent overheating, monitor the voltage and current of generators to ensure stable power output, and detect the temperature of transformers (using RTDs) to maintain their efficiency. By providing accurate and real-time data, the SPASI23 helps in optimizing the performance of power generation equipment, reducing downtime, and improving overall power plant efficiency.

Manufacturing plants rely on the SPASI23 for precise process control. In a food and beverage manufacturing line, it can measure the temperature of cooking vessels, the pressure of filling machines, and the flow rate of ingredients. The accurate data from the SPASI23 enables the control system to adjust process parameters in real-time, ensuring consistent product quality. In automotive manufacturing, it can be used to monitor the temperature of welding robots, the pressure of hydraulic presses, and the position of automated assembly equipment, contributing to the smooth operation of the production line.

Chemical processing plants also benefit greatly from the SPASI23. It can measure the pH levels of chemical reactions (using voltage sensors), the flow rate of chemical feedstocks (using current sensors), and the temperature of reactors (using TCs or RTDs). The module’s ability to handle a wide range of input signals and its high precision make it an ideal choice for chemical processing applications, where accurate process control is essential for safety and product quality.

ABB SPASI23

Related model recommendations

IMASI23: This is an older analog input module from ABB’s Bailey Infi 90 system, and the SPASI23 is the newer equivalent in the ABB Symphony Plus line. IMASI23 can be considered for legacy systems where compatibility with the existing infrastructure is a priority, while SPASI23 offers enhanced features and performance for new or upgraded installations.

SPASI32: A more advanced version of the SPASI23, the SPASI32 may offer additional channels or improved performance in certain areas such as higher precision or faster conversion times. It is suitable for applications that require a larger number of analog input channels or more demanding performance requirements.

CI854: A communication module from ABB, the CI854 can be paired with the SPASI23 to enhance its connectivity options. It enables the SPASI23 to communicate with other devices or systems using protocols like PROFINET, expanding the module’s integration capabilities in complex industrial networks.

AI810: Another analog input module by ABB, the AI810 has a different channel configuration and may be more suitable for applications with specific signal types or lower channel count requirements. It can be an alternative to the SPASI23 in scenarios where a smaller number of analog inputs are needed or where the input signal characteristics are different.

UFC719AE101: Although a multi-functional I/O interface module, the UFC719AE101 can work in tandem with the SPASI23 in larger automation systems. It can provide additional digital and analog I/O capabilities, complementing the SPASI23‘s analog input functionality and enabling a more comprehensive control solution.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the SPASI23, ensure that the DIN rail on which it will be mounted is clean, free of any debris, and properly secured. Use appropriate tools such as a torque wrench to fasten the module to the DIN rail, following the specified torque values. Verify that the power supply connected to the module is within the specified range of 24 V DC ±10%. Use shielded cables for connecting sensors to the module to minimize electromagnetic interference. Also, make sure to follow all safety guidelines, such as disconnecting the power supply before installation to prevent electrical shocks.

Maintenance suggestions: Regularly inspect the SPASI23 for any signs of physical damage, such as cracks in the casing or loose connections. Check the status LEDs on the module to ensure proper operation. Periodically calibrate the module using a certified calibration device to maintain its high precision. In case of communication or measurement issues, first check the cable connections and sensor functionality. If the problem persists, use ABB’s diagnostic tools to identify and resolve the issue. When replacing any components, always use genuine ABB parts to ensure compatibility and maintain the module’s performance and reliability.

Service and guarantee commitment

ABB stands firmly behind the SPASI23 with a comprehensive service and guarantee commitment. The module comes with a standard 2-year warranty, covering any manufacturing defects that may occur during normal use. ABB’s global network of technical support teams is available 24/7 to assist customers with installation, configuration, and troubleshooting. In the event of a problem, ABB guarantees a rapid response time, with a target of resolving critical issues within 4 hours.

For customers who require additional peace of mind, extended warranty options are available. ABB also offers on-site commissioning services, where experienced technicians will ensure that the SPASI23 is installed and configured correctly for optimal performance. In case a replacement is needed, ABB has a well – stocked inventory, enabling fast delivery of new modules to minimize downtime. This commitment to quality service and product reliability reflects ABB’s confidence in the SPASI23 and its dedication to customer satisfaction.