Description

| Parameter name | Parameter value |

| Product model | SPBRC410 |

| Manufacturer | ABB |

| Product category | Safety relay module (for machinery safety circuits) |

| Safety integrity level | SIL 3 (per IEC 61508), PL e (per ISO 13849-1) |

| Input channels | 4 normally open (NO) safety inputs |

| Output channels | 3 normally closed (NC) safety outputs, 1 auxiliary output |

| Operating voltage | 24 VDC ±15% |

| Response time | ≤ 15 ms |

| Communication interface | Ethernet/IP, PROFINET (for diagnostics) |

| Operating temperature range | -20°C to +60°C |

| Dimensions (LxWxH) | 120 mm x 80 mm x 60 mm |

| Weight | Approx. 0.3 kg |

| Mounting type | 35 mm DIN rail |

| Certifications | CE, UL, TÜV SÜD, CSA |

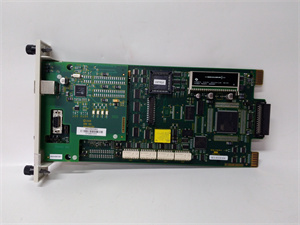

ABB SPBRC410

Product introduction

The ABB SPBRC410 is a high-performance safety relay module designed to monitor and control safety-critical circuits in industrial machinery. As part of ABB’s SafePlus™ safety product line, SPBRC410 serves as a core component in ensuring compliance with global safety standards, providing reliable protection for operators and equipment.

This module integrates advanced safety logic with diagnostic capabilities, enabling real-time monitoring of emergency stops, light curtains, and safety gates. In automation systems, SPBRC410 acts as a safety controller, interrupting hazardous machine motion within milliseconds of detecting a fault, while also communicating diagnostic data to the main PLC for proactive maintenance. Its compact design and broad safety certifications make it a versatile choice for industries where machinery safety is non-negotiable, from automotive assembly to packaging lines.

Core advantages and technical highlights

Safety-certified performance: SPBRC410 meets the highest global safety standards, including SIL 3 and PL e, ensuring it can be deployed in high-risk applications such as robotic welding cells. Unlike basic safety relays, it supports dual-channel input verification, where each safety signal is checked against a redundant path to eliminate false trips. This redundancy reduces unplanned downtime in critical processes, such as pharmaceutical filling lines where stopping production unnecessarily incurs significant costs.

Rapid response time: With a response time of ≤15 ms, SPBRC410 minimizes the risk of operator exposure to hazards. In an automotive stamping press application, this speed ensures the press stops before an operator’s hand enters the danger zone, even if the light curtain is breached suddenly. This performance exceeds the requirements of most machinery safety standards, providing an extra layer of protection in fast-moving environments.

Seamless system integration: SPBRC410 features Ethernet/IP and PROFINET communication, allowing it to integrate with ABB’s AC500 PLCs and third-party automation systems. This connectivity enables remote monitoring of safety circuit status, such as tracking which emergency stop button was activated, simplifying root-cause analysis. In a food processing plant with multiple packaging machines, maintenance teams can access SPBRC410 diagnostics via the plant SCADA, reducing troubleshooting time by up to 40%.

Flexible configuration: The module supports customizable safety logic via ABB’s Safety Builder software, eliminating the need for hardwired relays when adjusting safety circuits. For example, a beverage bottling line adding a new safety gate can reconfigure SPBRC410’s input mapping in minutes, avoiding production delays associated with rewiring. This flexibility makes it ideal for facilities with frequently updated machinery layouts.

Typical application scenarios

In automotive assembly plants, SPBRC410 is used to monitor safety circuits for robotic painting stations. It connects to light curtains around the robot cell, emergency stop buttons, and door interlocks. When a technician opens the cell door, SPBRC410 detects the interlock signal, cuts power to the robot’s drive system within 10 ms, and sends a fault code to the plant’s MES. This ensures compliance with ISO 10218-1 (robot safety) while allowing quick resumption of production once the door is closed and the circuit reset.

In logistics warehouses, SPBRC410 safeguards automated conveyor systems. It monitors pull-cord emergency stops along the conveyor length and safety switches on maintenance access panels. If a package jam triggers a pull-cord activation, SPBRC410 stops the conveyor and locks out restart until the jam is cleared and the cord reset. Its PROFINET connection to the warehouse’s WMS system logs the event, helping managers identify recurring jam points for process improvement.

In pharmaceutical manufacturing, SPBRC410 controls safety circuits for tablet presses. It integrates with pressure sensors and guard interlocks, ensuring the press shuts down if guards are removed during operation—a critical requirement for FDA compliance. The module’s SIL 3 certification provides auditors with documented proof of safety system reliability, simplifying regulatory inspections.

ABB SPBRC410

Related model recommendations

SPBRC310: A lower-channel variant of SPBRC410 (2 input channels) for smaller machinery like labelling machines.

SPBRC510: A higher-capacity model with 6 input channels, suitable for complex safety circuits in automotive welding lines.

AC500-S Safety PLC: ABB’s safety PLC that pairs with SPBRC410 for integrated safety and standard control in large-scale systems.

S3000 Compact: ABB’s light curtain series, often connected to SPBRC410 to form complete safety solutions for machine perimeters.

TB521: Terminal block for SPBRC410 that simplifies wiring of safety inputs/outputs and provides surge protection.

CI854A: PROFINET adapter that enhances SPBRC410’s communication with third-party PLCs in mixed-vendor systems.

SPASO23: Digital output module used alongside SPBRC410 to control non-safety actuators, such as status indicators.

SPBRC410-EXT: Expansion module for SPBRC410 that adds 4 extra input channels, ideal for retrofitting existing safety circuits.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing SPBRC410, verify the operating voltage (24 VDC) matches the power supply. Ensure the DIN rail is clean, grounded, and located away from high-voltage cables to avoid electromagnetic interference. Use insulated tools and ESD wristbands to prevent damage to internal components. Wiring must comply with local safety standards (e.g., NFPA 79 in the U.S.), with input/output cables separated from power cables to avoid noise. Allow 20 mm of clearance above/below for ventilation, especially in warm environments like foundries.

Maintenance suggestions: Inspect SPBRC410 quarterly for loose connections or corrosion, particularly in humid areas like food processing plants. Test safety circuits monthly by activating emergency stops and light curtains to confirm SPBRC410 triggers the machine shutdown within 15 ms (use an oscilloscope for verification). Update firmware annually via ABB’s Safety Builder software to ensure compliance with the latest safety standards. If a fault occurs, check the module’s LED status indicators first—red blinking indicates a safety circuit fault, while green steady indicates normal operation. Replace faulty units with genuine ABB SPBRC410 modules to maintain safety certifications.

Service and guarantee commitment

ABB provides a 3-year warranty for SPBRC410, covering defects in materials and workmanship. This warranty includes free technical support from ABB’s global safety experts, available 24/7 to assist with installation, configuration, and troubleshooting. Customers receive access to online training modules and safety certification guides to ensure proper deployment of SPBRC410.

For critical applications, ABB offers on-site commissioning services to validate safety circuit performance against ISO 13849-1. The company guarantees spare parts availability for 10 years post-production, ensuring long-term maintainability. ABB’s commitment to safety is underscored by SPBRC410’s compliance with global standards, reflecting confidence in its ability to protect operators and machinery in the most demanding environments.