Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

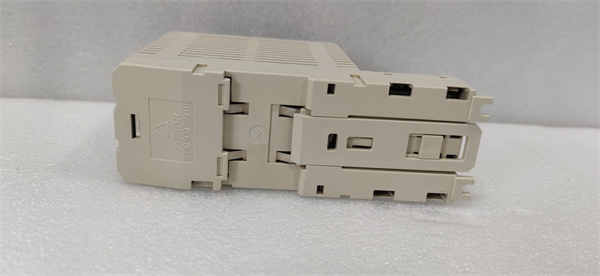

| Product model | TB820V2 3BSE013208R1 |

| Manufacturer | ABB |

| Product category | Terminal base for S800 I/O modules |

| Compatible series | S800 I/O modules (e.g., AI810, DO524) |

| Terminal type | Spring – clamp terminals, 24 terminals total |

| Wire size range | 0.2 mm² – 2.5 mm² (solid or stranded with ferrule) |

| Operating temperature | -40°C to +70°C |

| Storage temperature | -40°C to +85°C |

| Operating humidity | 10% – 95% (non – condensing) |

| Dimensions (W×H×D) | 22 mm × 109 mm × 70 mm |

| Weight | Approximately 0.12 kg |

| Installation method | DIN rail mounting (35 mm standard rail) |

| Protection class | IP20 |

| Compliance | CE, UL, ATEX |

| Marking | Pre – printed terminal labels for easy identification |

TB820V2 3BSE013208R1

Product introduction

The TB820V2 3BSE013208R1 is a high – performance terminal base developed by ABB for its S800 I/O module series. It serves as a critical connection hub between field devices (such as sensors, actuators) and I/O modules, providing a secure and organized interface for signal and power transmission in industrial automation systems.

As an upgraded version of earlier terminal bases, the TB820V2 3BSE013208R1 features enhanced spring – clamp terminals that ensure reliable wire connections even in vibrating industrial environments. It is designed to work seamlessly with modules like the AI810 3BSE008516R0001 (analog input) and DO524 A3 1SAP240700R0001 (digital output), forming a robust modular system. When paired with the TB806 3BSE008536R1 bus extension adaptor, it enables extended module bus configurations, allowing for flexible layout designs in control cabinets.

The terminal base simplifies wiring processes, reduces installation time, and enhances maintenance efficiency, making it an indispensable component in modern industrial control systems.

Core advantages and technical highlights

Time – saving installation

The TB820V2 3BSE013208R1 adopts spring – clamp terminals that eliminate the need for screws. Wires can be inserted directly and secured with a simple push of a lever, reducing wiring time by up to 50% compared to traditional screw – terminal bases. This feature is particularly beneficial in large – scale projects with hundreds of I/O points, such as automotive assembly lines, where rapid system deployment is critical.

Secure connections

The spring – clamp design of the TB820V2 3BSE013208R1 maintains consistent contact pressure over time, even in environments with continuous vibration (e.g., near industrial pumps or motors). This prevents loose connections and signal interruptions, ensuring stable data transmission between field devices and I/O modules. For example, in a chemical plant, it reliably transmits critical pressure and temperature signals from sensors to the AI810 3BSE008516R0001 module, avoiding process disruptions.

Flexible labeling and identification

Pre – printed terminal labels on the TB820V2 3BSE013208R1 simplify wire tracing and system documentation. Each terminal is clearly marked with standard identifiers (e.g., “IN1”, “OUT3”, “COM”), and additional blank labels are provided for custom naming. This reduces the risk of wiring errors during installation and speeds up troubleshooting in maintenance, especially in complex systems with multiple I/O modules.

TB820V2 3BSE013208R1

Typical application scenarios

In a water treatment plant, the TB820V2 3BSE013208R1 is widely used in the control cabinet of the filtration system. It serves as the terminal base for AI810 3BSE008516R0001 modules that monitor water flow, pressure, and turbidity. The spring – clamp terminals securely connect the 4 – 20 mA signals from flow meters and pressure transmitters, ensuring accurate data transmission to the PLC.

When the filtration system requires backwashing, the TB820V2 3BSE013208R1 paired with DO524 A3 1SAP240700R0001 modules sends control signals to solenoid valves, activating the backwash process. Its ability to withstand the humid environment of the plant (up to 95% humidity) ensures reliable operation, while the clear terminal labeling allows technicians to quickly identify and resolve any wiring issues during routine maintenance.

In conjunction with the TB806 3BSE008536R1 bus extension adaptor, the TB820V2 3BSE013208R1 enables the expansion of the I/O system across multiple DIN rails, adapting to the layout constraints of the plant’s control cabinet.

Related model recommendations

- TB806 3BSE008536R1: A bus extension cable adaptor that works with the TB820V2 3BSE013208R1to extend the module bus, allowing I/O modules on separate DIN rails to communicate.

- AI810 3BSE008516R0001: An analog input module directly mounted on the TB820V2 3BSE013208R1, which connects to sensors via its terminals for signal collection.

- DO524 A3 1SAP240700R0001: A digital output module that pairs with the TB820V2 3BSE013208R1to control actuators, using the terminal base for power and signal connections.

- TB825: A terminal base with higher current – carrying capacity (up to 10 A) for power – hungry devices, serving as an alternative to the TB820V2 3BSE013208R1in high – power applications.

- TU847: A universal terminal unit that complements the TB820V2 3BSE013208R1in large – scale systems, providing additional terminal points for complex wiring.

- SINT4611C: A power supply module that connects to the TB820V2 3BSE013208R1to provide stable 24 V DC power to I/O modules mounted on it.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the TB820V2 3BSE013208R1, ensure the DIN rail is clean, straight, and securely mounted in the control cabinet. The ambient temperature should be within -40°C to +70°C, and the relative humidity should not exceed 95% (non – condensing). Required tools include a small flat – head screwdriver (for releasing terminal levers) and wire strippers (to strip wires to 8 – 10 mm).

Turn off the system power to prevent electrical hazards. Align the TB820V2 3BSE013208R1 with the DIN rail and push it firmly until it clicks into place. Ensure there is at least 5 mm of space between adjacent terminal bases for heat dissipation.

Maintenance suggestions

For daily maintenance, visually inspect the TB820V2 3BSE013208R1 for signs of damage, such as cracked terminal levers or corrosion on the terminals. Check that all wires are securely clamped—gently tug each wire to ensure it does not loosen.

Clean the terminal base monthly with a soft brush or compressed air to remove dust, avoiding the use of liquids. If a terminal becomes damaged (e.g., a broken lever), replace the entire TB820V2 3BSE013208R1 to maintain connection integrity. When replacing, use ABB – genuine parts and ensure the power is off during installation to prevent short circuits.

Record the maintenance date and any issues found to track the performance of the terminal base over time.

Service and guarantee commitment

The TB820V2 3BSE013208R1 comes with a 3 – year warranty from ABB, covering defects in materials and workmanship under normal operating conditions. During the warranty period, ABB will replace or repair faulty units free of charge.

ABB’s global technical support team provides assistance with installation guidance, troubleshooting, and application advice via phone, email, or online portals. We also offer on – site training programs to help technicians master the proper installation and maintenance of the TB820V2 3BSE013208R1 and related S800 I/O components.

With a commitment to quality and reliability, ABB ensures that the TB820V2 3BSE013208R1 meets the rigorous demands of industrial automation, providing customers with long – term value and peace of mind.