Description

Detailed Parameter Table

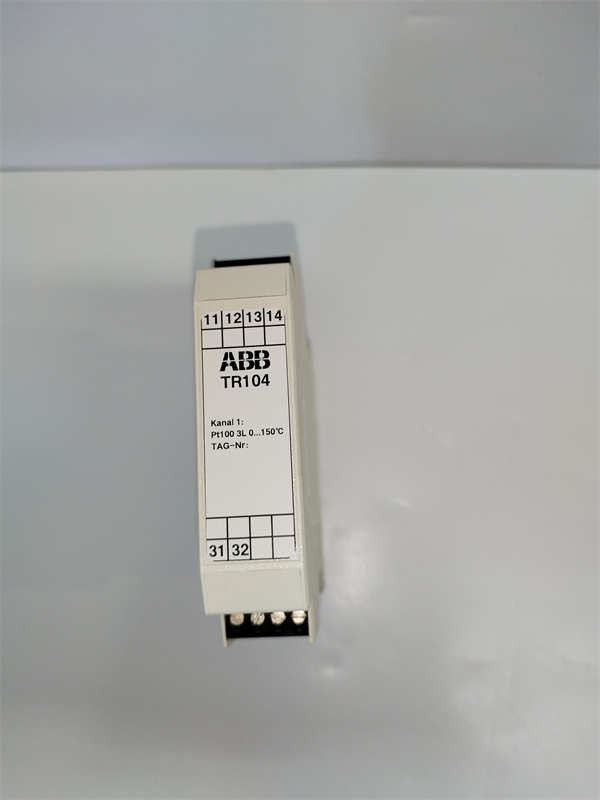

| Parameter Name | Parameter Value |

| Product Model | TR104 |

| Manufacturer | ABB |

| Product Category | Temperature relay |

| Measurement Range | -50°C to +150°C |

| Set Point Adjustment Range | -40°C to +140°C |

| Accuracy | ±1°C (at 0°C to +100°C) |

| Output Type | 1 changeover contact (NO/NC) |

| Maximum Switching Voltage | 250 V AC |

| Maximum Switching Current | 5 A (resistive load) |

| Response Time | ≤ 10 s (for temperature change of 50°C) |

| Protection Class | IP20 (when installed in control cabinet) |

| Dimensions (W×H×D) | 22.5 mm × 80 mm × 60 mm (approx.) |

| Weight | 0.08 kg (approx.) |

| Mounting | DIN rail mounting (35 mm) |

| Compatibility | Works with ABB SPBRC400 busbar trunking system, TU847 terminal unit |

| Certification | CE, UL |

ABB TR104

Product Introduction

The ABB TR104 is a compact and reliable temperature relay designed to monitor and control temperature in industrial environments. As a key component in thermal protection systems, it detects temperature changes and triggers switching actions to prevent equipment overheating or maintain optimal operating temperatures.

This relay features a wide measurement range of -50°C to +150°C, making it suitable for various applications, from cold storage facilities to high-temperature industrial processes. Its changeover contact (NO/NC) can be connected to alarms, contactors, or control systems via the ABB TU847 terminal unit, enabling automatic temperature regulation. When integrated with the ABB SPBRC400 busbar trunking system, it ensures that power to overheating equipment is 切断 (cut off) in a timely manner, protecting both machinery and the overall power distribution network.

Core Advantages and Technical Highlights

Precise Temperature Control

With an accuracy of ±1°C within the 0°C to +100°C range, the ABB TR104 provides precise temperature monitoring, critical for applications where temperature stability is paramount. For example, in a plastic extrusion plant, it can monitor the temperature of the extruder barrel. If the temperature exceeds the set point, the relay triggers a signal via the ABB TU847 terminal unit, which then adjusts the heating elements through the control system, ensuring consistent product quality.

Compact and Versatile Design

The ABB TR104‘s slim profile (22.5 mm width) allows for easy installation in crowded control cabinets, saving space. Its DIN rail mounting compatibility ensures quick integration into existing systems, alongside components like the ABB SPBRC400 busbar accessories. This versatility makes it ideal for both new installations and retrofits, adapting to diverse industrial setups without requiring major modifications.

Reliable Switching Performance

Equipped with a robust changeover contact, the ABB TR104 can handle switching voltages up to 250 V AC and currents up to 5 A, ensuring reliable operation even in demanding environments. Its response time of ≤10 s ensures rapid action during sudden temperature spikes, preventing equipment damage. In a data center powered by the ABB SPBRC400 system, the TR104 can monitor server room temperatures and activate cooling systems via the TU847 terminal unit before overheating occurs, maintaining uninterrupted server operation.

ABB TR104

Typical Application Scenarios

In industrial refrigeration systems, the ABB TR104 monitors the temperature of cooling coils. Connected to the ABB TU847 terminal unit, it sends signals to the compressor control circuit. If the temperature drops below the set point, the relay switches off the compressor to prevent freezing; when the temperature rises, it restarts the compressor. This automatic regulation ensures efficient cooling while protecting the system from damage, with the ABB SPBRC400 providing stable power to the entire setup.

In a boiler room, the ABB TR104 is installed to monitor water temperature. If the temperature exceeds the safe threshold, the relay triggers a contactor via the ABB TU847, 切断 (cutting off) power to the heating element. This prevents boiler overheating and potential explosions, with the relay’s quick response time minimizing risk. The integration with the ABB SPBRC400 busbar system ensures that power is safely disconnected without affecting other equipment.

In a warehouse with climate control, the ABB TR104 maintains optimal storage temperatures for sensitive goods like pharmaceuticals. It communicates with HVAC systems through the ABB TU847 terminal unit: if the temperature rises above the set point, the relay activates the air conditioning; if it drops too low, it switches on heaters. This precise control, supported by the stable power supply from the ABB SPBRC400, ensures product integrity.

Related Model Recommendations

- ABB TR105: A temperature relay with a higher maximum temperature range (+200°C), suitable for extreme high-temperature applications.

- ABB TU847: Terminal unit that facilitates wiring between the ABB TR104and control systems, ensuring organized and reliable connections.

- ABB SPBRC400: Busbar trunking system that works with the ABB TR104to provide power and enable safe shutdown of overheating equipment.

- ABB DO820 3BSE008514R1: Digital output module that can receive signals from the ABB TR104via the TU847, controlling power to heating/cooling devices.

- ABB SACE Tmax XT: Circuit breaker that, when paired with the ABB TR104, offers enhanced overcurrent and thermal protection for power systems.

- ABB RVAR-5612: Voltage regulator that ensures stable power supply to the ABB TR104, maintaining accurate temperature measurement.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the ABB TR104, ensure the control cabinet is clean and dry, with ambient temperature between -25°C and +70°C. Required tools include a screwdriver (PH1) and wire strippers. Mount the relay on a 35 mm DIN rail, near the temperature measurement point but away from direct heat sources. Connect the temperature sensor (thermocouple or RTD) to the relay’s input terminals, following polarity markings. Use the ABB TU847 terminal unit to connect the output contacts to the control system or load, ensuring wires are 0.5-1.5 mm² and stripped to 6 mm.

Commissioning Steps

After installation, set the desired temperature using the relay’s adjustment knob, referencing the scale. Connect power to the sensor and test the relay by applying heat or cold to the sensor. Verify that the output contact switches at the set point: use a multimeter to check continuity (NO contact closes, NC contact opens). Test integration with the ABB TU847 and connected devices, ensuring the control system receives the temperature signal and responds appropriately (e.g., activating an alarm). Monitor the relay’s LED indicator (if equipped) to confirm normal operation.

Maintenance Suggestions

For daily maintenance, inspect the ABB TR104 for dust accumulation and clean with a soft brush. Check wiring connections periodically to ensure tightness, especially at the ABB TU847 terminal unit. Calibrate the relay annually using a temperature bath or calibrator to maintain accuracy. If the relay fails to switch at the correct temperature, replace the sensor first; if issues persist, replace the relay with an ABB-approved spare. Keep a log of temperature readings and maintenance activities to track performance over time.

Service and Guarantee Commitment

The ABB TR104 comes with a 2-year warranty, covering defects in materials and workmanship under normal operating conditions. During the warranty period, ABB will repair or replace faulty relays free of charge. Our technical support team is available 24/7 to assist with installation, calibration, and troubleshooting via phone or email.

We provide detailed user manuals and calibration guides to support efficient deployment. Optional service contracts include on-site calibration and training. ABB is committed to ensuring the ABB TR104 delivers reliable temperature control, leveraging our expertise in industrial relays to protect your equipment and processes.