Description

Detailed parameter table

| Parameter name | Parameter value |

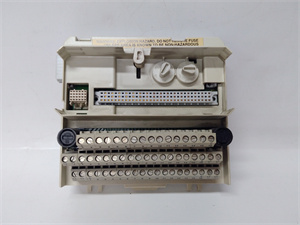

| Product model | TU830V1 |

| Manufacturer | ABB |

| Product category | Terminal unit for industrial control systems |

| Number of terminals | 32 terminals (16 input, 16 output) |

| Terminal type | Screw terminals, suitable for 0.5 – 2.5 mm² wires |

| Operating voltage | 24 V DC (auxiliary power) |

| Power consumption | Typical 3 W |

| Operating temperature range | -25°C to +60°C |

| Protection class | IP20 (when mounted in a control cabinet) |

| Dimensions (W×H×D) | 120 mm × 180 mm × 80 mm (approx.) |

| Weight | 0.5 kg (approx.) |

| Compatibility | Designed for use with ABB AC800M PLC and related I/O modules |

| Mounting | DIN rail mounting (35 mm) |

| Certification | CE, UL |

ABB TU830V1

Product introduction

The ABB TU830V1 is a compact and reliable terminal unit, specifically designed to simplify wiring connections in industrial control systems. As an integral part of ABB’s automation infrastructure, it serves as an interface between field devices (such as sensors, actuators, and switches) and the central control modules, streamlining the wiring process and enhancing system organization.

With 32 terminals (16 for inputs and 16 for outputs), the ABB TU830V1 provides a centralized connection point for various signal wires, reducing the complexity of wiring in control cabinets. Its compatibility with ABB AC800M PLCs and related I/O modules ensures seamless integration into existing ABB automation systems. Whether deployed in manufacturing plants, power facilities, or process industries, the ABB TU830V1 plays a crucial role in maintaining tidy and efficient wiring, facilitating easier installation, maintenance, and troubleshooting.

Core advantages and technical highlights

Simplified wiring management

The ABB TU830V1 excels in organizing complex wiring systems by providing a centralized terminal block. Instead of connecting field devices directly to I/O modules with numerous loose wires, the ABB TU830V1 allows for neat, grouped connections. This not only reduces the risk of wiring errors but also makes it easier to identify and trace individual wires during maintenance or system modifications. For example, in a manufacturing control cabinet with dozens of sensors and actuators, the ABB TU830V1 ensures that each signal wire has a designated terminal, simplifying the task of checking connections when a fault occurs.

Durable and reliable construction

Built with industrial-grade materials, the ABB TU830V1 is designed to withstand the harsh conditions of industrial environments. Its screw terminals provide secure connections, ensuring that wires remain firmly attached even in high-vibration settings. The unit can operate within a wide temperature range (-25°C to +60°C), making it suitable for use in cold storage facilities, high-temperature production areas, and other extreme environments. This durability ensures long-term reliability, minimizing the need for frequent replacements and reducing downtime.

Seamless system integration

The ABB TU830V1 is specifically engineered to work with ABB’s AC800M PLC system and compatible I/O modules, such as the ABB GDB021BE05 HIEE300766R0005 digital input module. This compatibility ensures that the terminal unit integrates smoothly into the overall control system, maintaining signal integrity and communication efficiency. The standardized design also allows for easy expansion—additional ABB TU830V1 units can be added to accommodate more field devices as the system grows, providing scalability for evolving industrial needs.

ABB TU830V1

Typical application scenarios

In automotive assembly lines, the ABB TU830V1 is widely used to connect various sensors and actuators to the control system. For instance, it serves as the connection point for proximity sensors that detect the presence of car parts on conveyor belts and for solenoid valves that control pneumatic tools. By centralizing these connections, the ABB TU830V1 simplifies the wiring between the field devices and the AC800M PLC, allowing maintenance technicians to quickly access and troubleshoot connections when issues arise, such as a sensor failing to detect a part. This ensures minimal disruption to the assembly process, keeping production on schedule.

In water treatment plants, the ABB TU830V1 plays a key role in connecting water quality sensors (e.g., pH, turbidity sensors) and control valves to the PLC system. The terminal unit’s secure terminals ensure reliable signal transmission from the sensors to the PLC, enabling accurate monitoring of water conditions. When the PLC sends commands to adjust valve positions (e.g., to regulate chemical dosing), the ABB TU830V1 facilitates the connection between the PLC’s output module and the valve actuators, ensuring precise control. Its ability to operate in damp environments makes it a reliable choice for the humid conditions often found in water treatment facilities.

In food processing plants, the ABB TU830V1 is used to connect temperature sensors, pressure switches, and motor starters to the control system. The unit’s organized terminal layout helps maintain compliance with strict hygiene standards, as it allows for easy cleaning around the wiring connections. For example, in a baking line, the ABB TU830V1 connects temperature sensors in ovens to the PLC, ensuring that the PLC receives accurate temperature readings to maintain consistent baking conditions. It also connects the motor starters of conveyor belts, enabling the PLC to control belt speed based on production needs.

Related model recommendations

- ABB TU840V1: A higher-capacity terminal unit with 64 terminals, ideal for larger systems requiring more connections than the ABB TU830V1can accommodate.

- ABB AC800M PLC: The central controller that pairs with the ABB TU830V1, using the terminal unit to interface with field devices and execute control logic.

- ABB GDB021BE05 HIEE300766R0005: A digital input module that connects to the ABB TU830V1, receiving signals from field sensors via the terminal unit’s input terminals.

- ABB GDO021BE05 HIEE300768R0005: A digital output module that works with the ABB TU830V1to send control signals from the PLC to actuators through the terminal unit’s output terminals.

- ABB CI867K01 3BSE043660R1: An Ethernet communication module that, when used with the ABB TU830V1and AC800M PLC, enables remote monitoring of the terminal unit’s connected devices.

- ABB TU820: A compact terminal unit with 16 terminals, serving as a smaller alternative to the ABB TU830V1for systems with fewer field devices.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the ABB TU830V1, ensure the control cabinet is clean, dry, and free from excessive dust or debris. The ambient temperature should be within -25°C to +60°C, and there should be sufficient space around the unit for wiring and maintenance. Required tools include a screwdriver (PH2), wire strippers, and a torque wrench (set to 0.5 – 0.8 Nm for terminal screws). Mount the ABB TU830V1 on a 35 mm DIN rail, ensuring it is securely fastened to prevent movement. Before connecting wires, verify that the auxiliary power supply (24 V DC) is disconnected to avoid electrical hazards. Use wires of the recommended size (0.5 – 2.5 mm²) and strip the insulation to the correct length (approx. 8 mm) for proper terminal connection.

Maintenance suggestions

For daily maintenance of the ABB TU830V1, inspect the terminal screws regularly to ensure they are tight—loose connections can cause signal loss or overheating. Clean the unit’s surface with a dry cloth to remove dust, which can accumulate and interfere with heat dissipation. Check for signs of corrosion on the terminals, especially in humid environments, and treat affected terminals with a corrosion inhibitor if necessary. When replacing wires or making modifications, label each wire clearly to maintain organization. If a terminal becomes damaged, replace the entire unit with an ABB-approved spare to ensure continued reliability. It is recommended to conduct a full wiring inspection every six months to identify and address any potential issues before they cause system faults.

Service and guarantee commitment

The ABB TU830V1 comes with a 2-year warranty, covering defects in materials and workmanship under normal operating conditions. During this period, ABB will replace any faulty units free of charge. Our global technical support team is available 24/7 to assist with installation guidance, troubleshooting, and technical inquiries via phone, email, or online chat.

We provide comprehensive online resources, including installation manuals, wiring diagrams, and compatibility guides, to support efficient deployment of the ABB TU830V1. For customers requiring additional support, optional service contracts offer on-site assistance, training sessions, and priority response times. ABB is committed to ensuring the ABB TU830V1 delivers reliable performance, backed by our expertise in industrial automation components, to keep your control systems running smoothly.