Description

Detailed parameter table

| Parameter name | Parameter value |

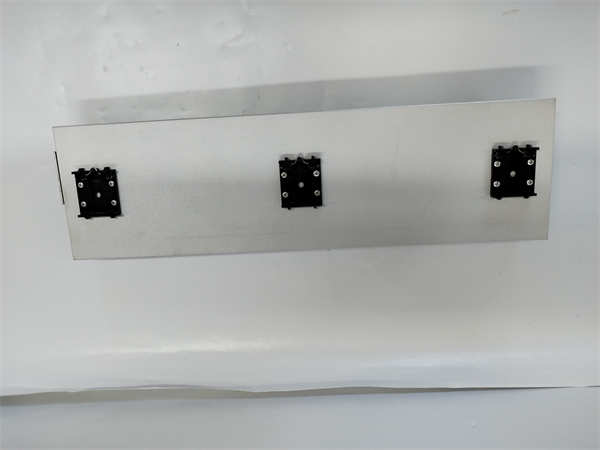

| Product model | UFC719AE101 3BHB003041R0101 |

| Manufacturer | ABB |

| Product category | Multi-functional I/O interface module |

| Digital I/O | 32 digital inputs, 32 digital outputs |

| Analog I/O | 8 analog inputs, 8 analog outputs |

| Communication protocols | CANopen, Modbus RTU/TCP, Ethernet/IP |

| Operating voltage | 24 V DC ±10% |

| Protection rating | IP65 |

| Dimensions (LxWxH) | 460 mm × 50 mm × 150 mm (18.1 in × 2.0 in × 5.9 in) |

| Weight | Approximately 1.27 kg (2.8 lb) |

| Operating temperature range | -20°C to +60°C (-4°F to +140°F) |

| Installation type | DIN rail or panel mount |

| Certification | IEC 61131-2, CE, UL, ATEX |

ABB UFC719AE101 3BHB003041R0101 3BHB00072R0101

Product introduction

The UFC719AE101 3BHB003041R0101 is a high-performance I/O interface module from ABB, designed to serve as a critical bridge between control systems and field devices in industrial automation. As part of ABB’s advanced I/O solution portfolio, this module integrates robust input/output capabilities with flexible communication, making it a versatile choice for complex automation environments.

UFC719AE101 3BHB003041R0101 stands out for its balanced combination of digital and analog I/O channels—32 digital inputs, 32 digital outputs, 8 analog inputs, and 8 analog outputs—enabling it to handle diverse signals from sensors, actuators, valves, and transducers. Its support for multiple protocols, including CANopen, Modbus, and Ethernet/IP, ensures seamless integration with PLCs, DCS, and SCADA systems, while the Ethernet interface facilitates remote monitoring and configuration. In automation systems, UFC719AE101 3BHB003041R0101 reduces wiring complexity, enhances data accuracy, and improves response times, making it indispensable for optimizing industrial processes.

Core advantages and technical highlights

Versatile I/O configuration: UFC719AE101 3BHB003041R0101 offers a comprehensive mix of 72 I/O channels, eliminating the need for multiple standalone modules. This integration reduces cabinet space usage by up to 30% compared to discrete I/O solutions, simplifying system design and lowering installation costs. The analog channels support various signal types (4-20 mA, 0-10 V), while digital channels handle fast switching (up to 10 kHz), catering to both steady-state and dynamic process needs.

Robust connectivity: With native support for CANopen, Modbus, and Ethernet/IP, UFC719AE101 3BHB003041R0101 seamlessly connects to legacy and modern control systems. This protocol flexibility ensures backward compatibility with existing infrastructure while enabling future upgrades to smart automation architectures. The built-in Ethernet port allows for real-time data transmission to cloud platforms or MES systems, supporting Industry 4.0 initiatives like predictive maintenance and process optimization.

Industrial-grade durability: Rated IP65, UFC719AE101 3BHB003041R0101 thrives in harsh environments, resisting dust, water jets, and chemical splashes common in food processing, chemical, and automotive plants. Its wide operating temperature range (-20°C to +60°C) ensures reliable performance in extreme conditions, from cold storage facilities to high-heat production areas, minimizing downtime due to environmental stress.

Typical application scenarios

In automotive assembly lines, UFC719AE101 3BHB003041R0101 excels at consolidating signals from diverse devices: digital inputs monitor limit switches on robotic arms, analog inputs track pressure in welding clamps, and digital outputs control conveyor belt motors. Its fast response time (≤1 ms for digital signals) ensures synchronized operation between stations, reducing cycle times and improving assembly precision. The module’s Ethernet/IP connectivity allows plant managers to remotely monitor line performance, quickly identifying bottlenecks.

Within chemical processing plants, UFC719AE101 3BHB003041R0101 handles corrosive and humid conditions thanks to its IP65 rating. It connects to pH sensors (analog inputs), solenoid valves (digital outputs), and flow meters, relaying critical process data to the DCS via Modbus. This real-time data flow enables tight control over reaction parameters, ensuring compliance with safety standards and reducing waste from process deviations.

In food and beverage facilities, UFC719AE101 3BHB003041R0101 supports washdown procedures without performance loss. It manages temperature sensors in pasteurizers (analog inputs) and controls filling machine actuators (digital outputs), with CANopen facilitating communication with batch controllers to maintain product consistency across shifts.

ABB UFC719AE101 3BHB003041R0101 3BHB00072R0101

Related model recommendations

UFC720AE101: An upgraded variant of UFC719AE101 3BHB003041R0101 with 48 digital I/O and 16 analog channels, ideal for larger-scale applications requiring expanded capacity.

CI854: ABB’s PROFINET communication module that pairs with UFC719AE101 3BHB003041R0101 to add PROFINET connectivity, enhancing integration with ABB’s AC 800M DCS.

PM590: A high-performance PLC from ABB’s AC 500 series, designed to work seamlessly with UFC719AE101 3BHB003041R0101 for centralized control of I/O signals.

TB820: A terminal base accessory for UFC719AE101 3BHB003041R0101, providing secure wiring connections and surge protection in high-vibration environments.

UAD149A0011: An analog input module that complements UFC719AE101 3BHB003041R0101 in systems needing additional high-precision analog channels for scientific instrumentation.

D0810: A digital output module compatible with UFC719AE101 3BHB003041R0101, offering relay-based outputs for high-power devices like heaters or large motors.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing UFC719AE101 3BHB003041R0101, ensure the mounting surface (DIN rail or panel) is clean, flat, and capable of supporting the module’s weight. Use a torque wrench (set to 1.5 Nm) for securing the module, and verify the 24 V DC power supply is isolated and protected by a 2A fuse. Use shielded twisted-pair cables for analog signals to minimize electromagnetic interference, and route power cables separately from signal cables. For IP65 compliance, ensure cable entries are sealed with approved glands, and maintain a minimum 50 mm clearance around the module for ventilation.

Maintenance suggestions: Conduct monthly visual inspections of UFC719AE101 3BHB003041R0101 to check for loose connections, corrosion, or damage to the enclosure. Clean the exterior with a damp cloth (avoiding water ingress) to remove dust or debris. Calibrate analog channels annually using a certified signal generator to maintain accuracy. If communication faults occur, check protocol settings via the Ethernet interface or replace faulty cables; for I/O issues, use the module’s diagnostic LEDs to isolate problematic channels. When replacing components, use only ABB-approved spare parts to preserve IP65 integrity and certification compliance.

Service and guarantee commitment

UFC719AE101 3BHB003041R0101 is backed by a 3-year warranty from ABB, covering manufacturing defects and performance issues under normal operating conditions. ABB’s global technical support team provides 24/7 assistance for installation, configuration, and troubleshooting, with response times guaranteed within 4 hours for critical issues.

We offer on-site commissioning services, including I/O mapping, protocol configuration, and integration testing, performed by certified engineers to ensure UFC719AE101 3BHB003041R0101 operates at peak efficiency. Extended warranty options (up to 5 years) are available, including annual preventive maintenance checks. In the event of a fault, ABB guarantees a 72-hour repair turnaround, with replacement modules available for next-day delivery to minimize downtime. All services use genuine ABB components, ensuring UFC719AE101 3BHB003041R0101 maintains its original performance and reliability.