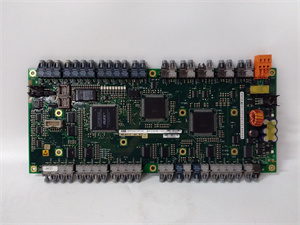

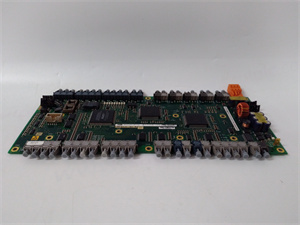

Description

| Parameter name | Parameter value |

| Product model | UFC760BE1142 |

| Manufacturer | ABB |

| Product category | Industrial automation interface module, specializing in signal processing and system integration |

| Input voltage | 24 VDC ± 20% |

| Communication interfaces | Ethernet for high – speed data transfer, serial interfaces (RS – 232/RS – 485) for versatile connectivity, and supports Modbus protocol for seamless integration with a wide range of devices |

| Safety level | PL e, with 8 digital safety inputs, meeting SIL 3 – SILCL 3 – PL e – Cat. 4 standards |

| Operating temperature | – 10°C to 55°C, suitable for diverse industrial environments |

| Storage temperature | – 20°C to + 85°C |

| Dimensions (HxWxD) | 108 mm x 22.5 mm x 114.5 mm, compact for easy installation in industrial enclosures |

| Mounting method | DIN – rail mounting, compliant with EN 50022 – 35 standard for secure and convenient installation |

| Protection class | IP20 for the enclosure, protecting against solid objects larger than 12 mm; IP2X for the terminal block, providing protection against accidental contact |

| Signal display | LED indicators for operating status and fault diagnosis, with LED indication of input conditions for easy monitoring |

| Fiber optic options | Supports multi – mode fibers (50/125um, 62.5/125um, 100/140um) and single – mode fibers (8.3/125um, 9/125um, 10/125um) for long – distance and high – speed data transmission |

| Additional I/O features | 8 – channel digital input and 4 – channel test output for extended functionality |

UFC760BE1142

Product introduction

The UFC760BE1142 by ABB is a high – performance industrial automation interface module, designed to meet the complex demands of modern industrial control systems. As an integral part of ABB’s extensive product portfolio, this module combines advanced technology with robust construction to ensure seamless operation in various industrial settings.

This module serves as a crucial link between different components in an industrial automation setup. With its multiple communication interfaces, including Ethernet and serial ports supporting Modbus, the UFC760BE1142 enables efficient data transfer and communication between sensors, actuators, and the main control system. Its ability to handle a wide range of input signals, such as digital inputs and analog signals from various sensors, makes it highly versatile. The UFC760BE1142 is engineered to process and transmit data accurately, contributing to the overall precision and reliability of industrial processes. Whether in a manufacturing plant, a power generation facility, or a water treatment plant, this module plays a vital role in optimizing system performance and ensuring smooth operation.

Core advantages and technical highlights

High – precision signal processing: The UFC760BE1142 is equipped with advanced signal – processing algorithms, allowing for accurate handling of analog and digital signals. In applications where precise measurement and control are critical, such as in pharmaceutical manufacturing or semiconductor production, the module can accurately process sensor data, ensuring that production processes are maintained within tight tolerances. For example, it can precisely measure the temperature or pressure in a reaction vessel and transmit this data to the control system for immediate action.

Enhanced safety features: With a high safety level of PL e and 8 digital safety inputs meeting SIL 3 – SILCL 3 – PL e – Cat. 4 standards, the UFC760BE1142 is designed with safety as a top priority. In hazardous industrial environments, such as chemical plants or oil refineries, these safety features help prevent accidents. The module can detect abnormal conditions, such as over – current or over – temperature, and take immediate corrective actions, such as shutting down equipment or activating alarms, to protect personnel and equipment.

Flexible communication capabilities: The module’s support for multiple communication interfaces, including Ethernet, serial interfaces, and Modbus, provides unparalleled flexibility in system integration. It can easily communicate with a wide range of devices, from legacy equipment to the latest smart sensors and actuators. In a large – scale industrial complex with a mix of old and new equipment, the UFC760BE1142 can bridge the communication gap, allowing for seamless data exchange and control. Additionally, its support for fiber – optic connections, including multi – mode and single – mode fibers, enables high – speed and long – distance data transmission, reducing the impact of electromagnetic interference.

Compact and rugged design: With its compact dimensions of 108 mm x 22.5 mm x 114.5 mm and DIN – rail mounting option compliant with EN 50022 – 35 standard, the UFC760BE1142 is easy to install in industrial enclosures. Its IP20 – rated enclosure and IP2X – rated terminal block protect against solid objects and accidental contact, respectively, ensuring reliable operation in harsh industrial environments. The module’s robust construction allows it to withstand vibrations, dust, and temperature variations, making it suitable for use in factories, mines, and outdoor installations.

Typical application scenarios

In manufacturing industries, the UFC760BE1142 is widely used in production lines. For example, in an automotive assembly plant, it can connect various sensors, such as proximity sensors, temperature sensors, and pressure sensors, to the central control system. The module processes the data from these sensors, which helps in monitoring and controlling the movement of robotic arms, conveyor belts, and other equipment. It ensures that the assembly process is carried out accurately and efficiently, reducing errors and improving productivity.

In power generation facilities, the UFC760BE1142 plays a crucial role in monitoring and controlling power – related parameters. It can connect to sensors that measure voltage, current, and frequency in generators and transformers. By accurately processing and transmitting this data to the control system, the module helps in maintaining the stability of the power grid. In case of any abnormal conditions, such as voltage fluctuations or over – current, it can trigger protective actions to prevent equipment damage and ensure continuous power supply.

In water treatment plants, the module is used to control and monitor the water treatment process. It can connect to sensors that measure water quality parameters, such as pH, turbidity, and chlorine levels, as well as actuators that control pumps, valves, and other equipment. The UFC760BE1142 processes the sensor data and sends control signals to the actuators, ensuring that the water treatment process is optimized. This helps in producing clean and safe water while minimizing energy consumption and chemical usage.

UFC760BE1142

Related model recommendations

UFC760BE42: This is a related interface board in the same product family. It has similarities in functionality but may have differences in specific parameter settings. For example, it might be more focused on basic data storage and buffering tasks, making it suitable for less complex applications where the UFC760BE1142‘s advanced features are not fully required.

PM864: ABB’s DCS controller that can be integrated with the UFC760BE1142. The PM864 provides overall system control, while the UFC760BE1142 handles local input/output and signal processing functions. Together, they form a comprehensive solution for industrial automation systems, enabling efficient control and monitoring of industrial processes.

CI854: A PROFIBUS DP communication module. When integrated with the UFC760BE1142, it enhances the module’s communication capabilities, allowing it to connect with a wider range of PROFIBUS – compatible devices in an industrial network. This is beneficial for applications where seamless integration with other PROFIBUS – based equipment is necessary.

DI810: A 16 – channel digital input module. In applications where the UFC760BE1142 needs to interface with a large number of digital sensors or signals, the DI810 can be connected to expand the digital input capacity. This provides more flexibility in data collection and control, especially in complex industrial setups with numerous digital devices.

AO820: An 8 – channel analog output module. It can be paired with the UFC760BE1142 when there is a requirement for controlling analog – actuated devices, such as variable – speed drives or proportional valves. The combination allows for precise control of analog – based processes in industrial applications.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the UFC760BE1142, ensure that the installation environment meets the specified temperature (- 10°C to 55°C) and humidity requirements. Use a DIN – rail that complies with EN 50022 – 35 standard for mounting. Prepare appropriate tools, such as screwdrivers and wire strippers, for installation. Verify the integrity of the 24 VDC power supply, ensuring that it is stable and free from voltage spikes. When connecting wires to the terminal block, follow the wiring diagram provided in the product manual carefully and use high – quality wires to ensure reliable connections.

Commissioning: Power on the UFC760BE1142 and start the configuration process. Use ABB – provided software or configuration tools to set the communication parameters, such as IP addresses for Ethernet and baud rates for serial interfaces. Calibrate the analog and digital input/output channels using appropriate calibration tools. Connect the module to a test load, such as a simple sensor or actuator, and verify that the data is being transmitted and received correctly. Conduct a series of tests to check the module’s response to different input signals and operating conditions. Ensure that the LED indicators for status and fault diagnosis are working properly.

Maintenance suggestions: Regularly inspect the UFC760BE1142 for any signs of physical damage, such as cracks in the enclosure or loose connections. Clean the module periodically to remove dust and debris, especially in dusty industrial environments. Monitor the operating temperature of the module using a temperature sensor. In case of any malfunction, use ABB’s diagnostic tools to identify the problem. Replace faulty components with genuine ABB parts to maintain the module’s performance and reliability. Check the communication interfaces regularly to ensure that data transfer is smooth and error – free.

Service and guarantee commitment

ABB stands firmly behind the UFC760BE1142 with a comprehensive service and guarantee commitment. The product comes with a standard warranty period, during which ABB will replace any defective units at no cost to the customer. ABB’s global technical support team is available 24/7 to provide assistance with any technical issues related to the module. Whether it’s a problem with installation, configuration, or operation, customers can rely on ABB’s expertise.

Customers can access a wealth of online resources, including detailed user manuals, technical documentation, and software updates, through ABB’s dedicated customer portal. Additionally, ABB offers optional on – site services, such as installation guidance, commissioning support, and maintenance training. This commitment reflects ABB’s confidence in the quality and reliability of the UFC760BE1142 and its dedication to ensuring customer satisfaction and minimizing system downtime.