Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | UFC760BE142 3BHE004573R0142 |

| Manufacturer | ABB |

| Product category | Industrial control unit |

| Core function | Process control, signal processing, and system coordination |

| Input channels | 16 analog inputs (4-20 mA, 0-10 V), 24 digital inputs (24 V DC) |

| Output channels | 8 analog outputs (4-20 mA), 16 digital outputs (relay, 24 V DC) |

| Communication protocols | Modbus TCP, Profibus DP, Ethernet/IP |

| Processor | 32-bit RISC, 800 MHz |

| Memory | 2 GB RAM, 16 GB flash storage |

| Power supply | 24 V DC ±15% |

| Operating temperature | -10°C to 60°C |

| Dimensions | 220 mm × 180 mm × 100 mm |

| Mounting type | DIN rail mount (35 mm) |

| Protection rating | IP20 |

| Certifications | IEC 61131-3, CE, UL, ATEX |

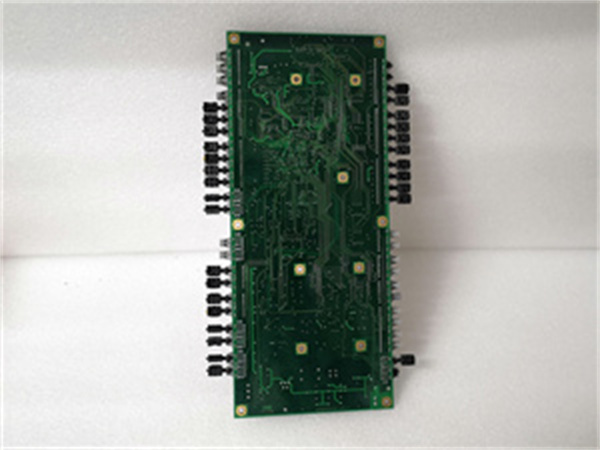

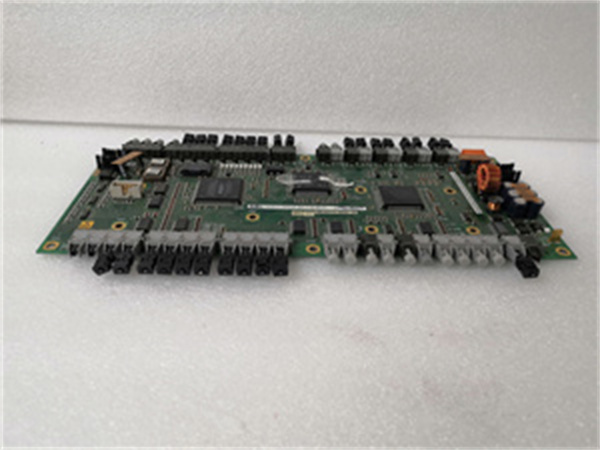

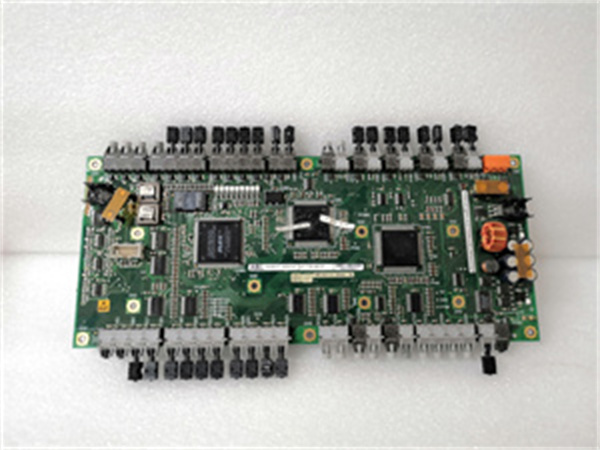

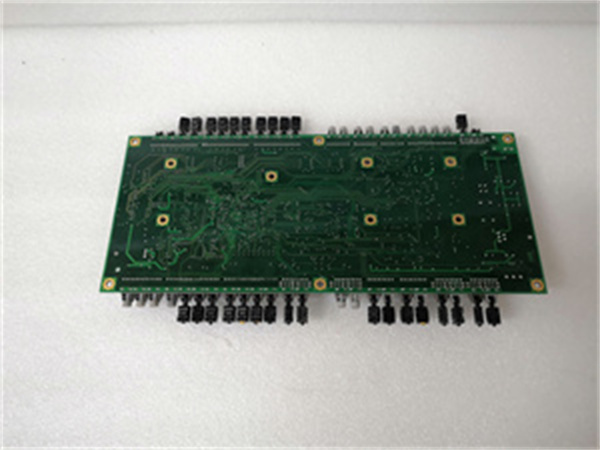

ABB UFC760BE142 3BHE004573R0142

Product introduction

The UFC760BE142 3BHE004573R0142 is a high-performance industrial control unit from ABB, engineered to deliver precise process control and seamless system integration in complex industrial environments. As a key component in ABB’s Advant Controller series, UFC760BE142 3BHE004573R0142 combines robust signal processing capabilities with flexible communication options, making it suitable for a wide range of applications from manufacturing lines to process plants.

Designed to handle both analog and digital signals, UFC760BE142 3BHE004573R0142 serves as a central hub for monitoring and controlling various field devices, including sensors, actuators, and other automation components. Its powerful 32-bit RISC processor ensures fast data processing, while support for multiple communication protocols enables easy integration with existing DCS, PLC, and SCADA systems. Whether deployed in chemical processing, power generation, or food and beverage production, UFC760BE142 3BHE004573R0142 provides reliable and accurate control, enhancing operational efficiency and reducing downtime.

Core advantages and technical highlights

Versatile signal handling: UFC760BE142 3BHE004573R0142 offers 16 analog inputs, 24 digital inputs, 8 analog outputs, and 16 digital outputs, providing comprehensive coverage for diverse industrial signals. This versatility allows it to connect to a wide range of field devices, from pressure and temperature sensors (via analog inputs) to motor starters and solenoid valves (via digital outputs). In a water treatment plant, for example, it can monitor pH levels (analog input), detect valve positions (digital inputs), and control chemical dosing pumps (analog outputs) and alarm systems (digital outputs) in a single unit.

Advanced communication capabilities: With support for Modbus TCP, Profibus DP, and Ethernet/IP, UFC760BE142 3BHE004573R0142 seamlessly integrates with various industrial networks, enabling real-time data exchange with higher-level control systems. This connectivity allows operators to monitor processes remotely, adjust setpoints, and troubleshoot issues from a central SCADA interface. In a manufacturing facility, this means the control unit can share production data with an MES system, facilitating better resource planning and quality control.

High processing performance: Equipped with a 32-bit RISC processor running at 800 MHz and 2 GB of RAM, UFC760BE142 3BHE004573R0142 processes complex control algorithms and handles large volumes of data with minimal latency. This ensures rapid response to changing process conditions, such as sudden pressure spikes in a chemical reactor, where the control unit can adjust valve positions within milliseconds to maintain safe operation. The 16 GB flash storage also allows for local logging of process data, supporting trend analysis and compliance reporting.

Rugged design for industrial environments: UFC760BE142 3BHE004573R0142 is built to withstand harsh industrial conditions, with an operating temperature range of -10°C to 60°C and ATEX certification for use in potentially explosive atmospheres. Its robust construction ensures reliable performance in dusty, humid, or vibration-prone settings, such as mining operations or heavy machinery plants. The 24 V DC power supply with ±15% tolerance adds to its resilience, allowing it to operate stably even with fluctuations in the power grid.

Typical application scenarios

In a chemical processing plant, UFC760BE142 3BHE004573R0142 controls a batch reactor system. The control unit’s analog inputs monitor temperature, pressure, and 液位 (liquid level) inside the reactor, while digital inputs track the status of safety interlocks and valve positions. Based on preprogrammed control logic, UFC760BE142 3BHE004573R0142 adjusts the flow of heating/cooling fluids (via analog outputs to control valves) and triggers 搅拌器 (stirrer) operation (via digital outputs). Its Ethernet/IP connection sends real-time data to the plant’s DCS, allowing operators to oversee the batch process and intervene if necessary, ensuring consistent product quality and adherence to safety standards.

In a food and beverage bottling plant, UFC760BE142 3BHE004573R0142 coordinates the filling and capping process. Digital inputs from photoelectric sensors detect bottle presence and position, while analog inputs monitor fill level and pressure in the filling nozzles. The control unit uses this data to activate filling valves (digital outputs) and adjust fill volume (analog outputs) based on bottle size, which is selected via a HMI connected through Modbus TCP. During a sudden bottleneck, UFC760BE142 3BHE004573R0142 quickly reduces the conveyor speed (via analog output to a variable frequency drive), preventing bottle jams and minimizing product waste.

ABB UFC760BE142 3BHE004573R0142

Related model recommendations

ABB ACS800-01-0025-3: A frequency converter that works with UFC760BE142 3BHE004573R0142 to control motor speed in conveyor systems.

ABB DSCA114 57510001-AA: An analog input module that expands the signal acquisition capabilities of UFC760BE142 3BHE004573R0142.

ABB NBIO-31 3BSE011337R1: A digital I/O module that complements UFC760BE142 3BHE004573R0142 for additional discrete signal handling.

ABB CI854A 3BSE022469R1: A Profinet communication module that enhances the network connectivity of UFC760BE142 3BHE004573R0142.

ABB AFP9075355 3BHS537443: A power supply unit that provides stable 24 V DC power to UFC760BE142 3BHE004573R0142.

ABB TB857: A surge protection device that safeguards UFC760BE142 3BHE004573R0142 from voltage spikes in industrial networks.

Installation, commissioning and maintenance instructions

Installation preparation: Mount UFC760BE142 3BHE004573R0142 on a 35 mm DIN rail in a control cabinet, ensuring at least 50 mm of clearance above and below for ventilation. Connect the 24 V DC power supply using 1.5 mm² cable, protected by a 2 A fuse. Wire input and output signals using shielded twisted-pair cable (0.5-1 mm² for analog signals, 0.75-1.5 mm² for digital signals), with shields grounded at the control unit end. Configure communication parameters (IP address, protocol settings) via the front-panel USB port using ABB’s Control Builder software before connecting to the network. Power off all connected devices during installation.

Maintenance suggestions: Inspect UFC760BE142 3BHE004573R0142 quarterly for loose connections, dust accumulation, and LED status indicators (power: green, communication: flashing yellow, fault: red). Clean the unit with compressed air to remove dust from ventilation slots. Calibrate analog inputs and outputs semi-annually using a precision signal generator to ensure accuracy within ±0.1% of full scale. Backup configuration data monthly to a USB drive to facilitate quick recovery in case of memory loss. If a communication failure occurs, check network cables and settings before replacing the unit—use only ABB-certified replacements to maintain system compatibility.

Service and guarantee commitment

UFC760BE142 3BHE004573R0142 is backed by a 5-year warranty from the date of installation, covering manufacturing defects and ensuring compliance with published performance specifications. ABB’s technical support team provides 24/7 response for critical issues, with remote diagnostics available to minimize downtime. On-site service is available within 72 hours in major industrial regions for complex commissioning or repair needs.

The warranty includes access to software updates, technical documentation, and training materials. Extended service contracts offer annual preventive maintenance, including calibration checks and performance optimization, to maximize the control unit’s lifespan and reliability. ABB’s commitment to quality underscores confidence in UFC760BE142 3BHE004573R0142 as a dependable solution for industrial control applications.