Description

Detailed parameter table

| Parameter name | Parameter value |

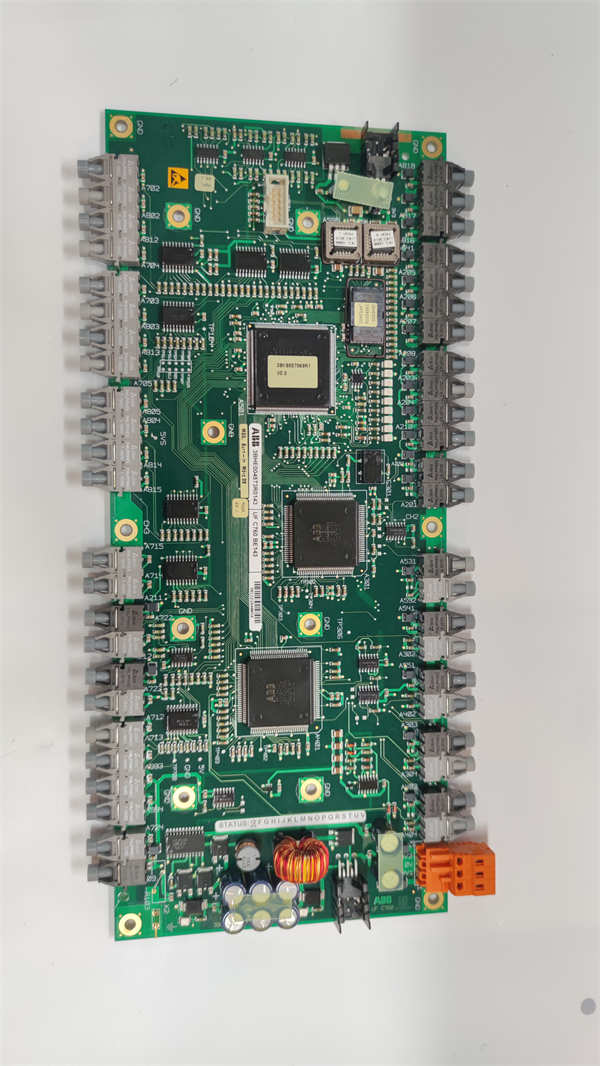

| Product model | UFC760BE143 3BHE004573R0143 |

| Manufacturer | ABB |

| Product category | Analog Input/Output Module |

| Analog inputs | 8 channels, 4-20 mA / 0-10 VDC |

| Analog outputs | 4 channels, 4-20 mA (isolated) |

| Input resolution | 16-bit |

| Output resolution | 16-bit |

| Input accuracy | ±0.1% of full scale |

| Output accuracy | ±0.1% of full scale |

| Communication interface | Profibus DP |

| Operating voltage | 24 VDC ±10% |

| Power consumption | Max 8 W |

| Operating temperature range | -25°C to +70°C |

| Dimensions (LxWxH) | 140 mm x 35 mm x 110 mm |

| Weight | Approximately 0.25 kg |

| Mounting type | DIN rail |

| Protection class | IP20 |

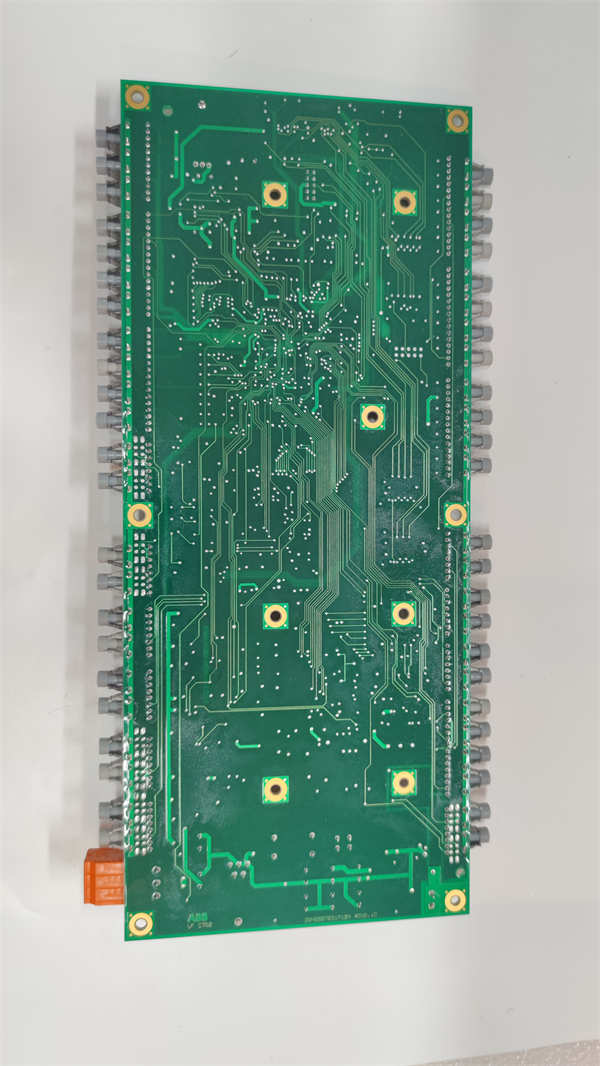

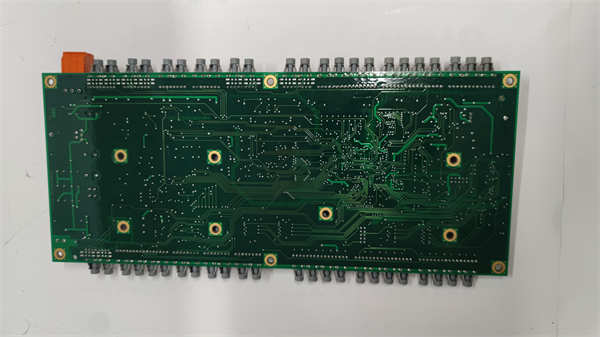

ABB UFC760BE143 3BHE004573R0143

Product introduction

The ABB UFC760BE143 3BHE004573R0143 is a high-precision analog input/output module designed for industrial process control systems, part of ABB’s renowned Advant OCS (Open Control System) portfolio. This module serves as a critical interface between field instruments (such as pressure transmitters, flow meters, and temperature sensors) and the central control system, enabling accurate data acquisition and precise actuation control.

With 8 analog inputs and 4 analog outputs, the UFC760BE143 3BHE004573R0143 excels in applications requiring real-time monitoring and adjustment of process variables. Its 16-bit resolution and ±0.1% accuracy ensure that even minor changes in pressure, temperature, or flow are captured and converted into actionable control signals. In chemical processing plants, water treatment facilities, or manufacturing lines, the ABB UFC760BE143 3BHE004573R0143 guarantees reliable communication between sensors, controllers, and actuators, forming the backbone of closed-loop process control.

Core advantages and technical highlights

Exceptional measurement precision: The UFC760BE143 3BHE004573R0143 delivers 16-bit resolution and ±0.1% accuracy across its input and output channels, making it ideal for applications where tight process tolerances are critical. In pharmaceutical manufacturing, for example, it can precisely measure and control pH levels in reactor vessels, ensuring compliance with strict quality standards. Even at the extremes of its operating range (e.g., 4 mA or 20 mA), the module maintains accuracy, eliminating drift-related errors that could compromise product quality.

Isolated outputs for enhanced safety: Each of the 4 analog outputs on the UFC760BE143 3BHE004573R0143 is galvanically isolated, preventing ground loops and electrical noise from affecting control signals. In industrial environments with multiple grounded devices (such as motor drives and heaters), this isolation protects sensitive actuators like control valves from voltage spikes, reducing the risk of premature failure. For instance, in a pulp and paper mill, where electrical noise is prevalent, the module ensures valve position signals remain stable, maintaining consistent paper thickness.

Broad environmental resilience: Rated to operate from -25°C to +70°C, the UFC760BE143 3BHE004573R0143 thrives in harsh industrial conditions. Whether installed in a freezing cold storage facility monitoring refrigerant levels or a high-temperature steel mill tracking furnace temperatures, the module performs reliably. Its resistance to vibration (up to 10 g) and shock (up to 50 g) further ensures durability in settings like oil refineries, where equipment is subject to constant mechanical stress.

Seamless Profibus integration: The built-in Profibus DP interface allows the UFC760BE143 3BHE004573R0143 to communicate with PLCs and DCS systems at data rates up to 12 Mbps, enabling real-time data exchange in large-scale automation networks. In a water treatment plant with distributed sensor arrays, this high-speed communication ensures that flow rate data from remote pipelines reaches the central SCADA system instantly, allowing for timely adjustments to pump speeds or valve positions.

Typical application scenarios

In chemical processing plants, the UFC760BE143 3BHE004573R0143 monitors and controls reactor conditions. Its 8 inputs connect to temperature, pressure, and level sensors in a batch reactor, while the 4 outputs regulate heating elements, cooling water valves, and agitator speed. The module’s precision ensures that reaction temperatures stay within ±0.5°C of the setpoint, critical for producing consistent chemical compounds. Profibus connectivity allows operators in a central control room to adjust setpoints remotely, reducing the need for on-site intervention in hazardous areas.

Water and wastewater treatment facilities utilize the UFC760BE143 3BHE004573R0143 to manage filtration and disinfection processes. Inputs measure turbidity, chlorine levels, and flow rates in filtration tanks, while outputs control chemical dosing pumps and backwash valves. During peak demand, the module’s fast response time (≤10 ms) allows it to adjust chlorine dosage within seconds of detecting a spike in turbidity, ensuring water safety without overusing chemicals.

Food and beverage production lines rely on the UFC760BE143 3BHE004573R0143 to maintain product consistency. In a dairy plant, it monitors pasteurization temperatures (via thermocouple transmitters) and controls the flow of milk through heat exchangers. The module’s accuracy ensures that milk is heated to exactly 72°C for 15 seconds—no more, no less—preserving taste while eliminating harmful bacteria. Its isolated outputs prevent electrical noise from nearby packaging machinery from disrupting temperature control signals.

ABB UFC760BE143 3BHE004573R0143

Related model recommendations

UFC761BE144 3BHE004574R0144: A sister model with 16 analog inputs and 8 outputs, designed for larger-scale processes requiring more I/O points, such as multi-tank brewing systems.

UFC719AE01: A digital I/O module that complements the UFC760BE143 3BHE004573R0143 in mixed-signal systems, handling on/off signals from limit switches while the UFC760BE143 manages analog variables.

AC800M: ABB’s modular PLC that pairs with the UFC760BE143 3BHE004573R0143, processing analog data to execute control logic in complex industrial processes.

CI854A: A Profibus DP communication module that extends the UFC760BE143 3BHE004573R0143’s network reach, enabling integration into larger Profibus networks with hundreds of nodes.

TB521: A terminal block accessory with surge protection, simplifying wiring for the UFC760BE143 3BHE004573R0143 in outdoor or high-noise environments like oil rigs.

AI830F: An 8-channel analog input module with HART support, used alongside the UFC760BE143 3BHE004573R0143 when digital communication with smart sensors (e.g., pressure transmitters) is required.

AO820: A 16-channel analog output module that expands the UFC760BE143 3BHE004573R0143’s actuation capabilities, ideal for controlling large banks of valves in water distribution networks.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the UFC760BE143 3BHE004573R0143, ensure the DIN rail is clean, level, and securely mounted to a grounded metal surface. Use ESD-safe tools and anti-static wristbands to avoid damaging the module’s sensitive electronics. Verify the 24 VDC power supply is fused at 1A and isolated from high-voltage circuits. For wiring, use twisted-pair shielded cables (0.5-1.5 mm²) for analog signals, terminating shields at both ends to minimize noise. Keep input/output wiring separate from power cables to prevent interference.

Maintenance suggestions: Inspect the UFC760BE143 3BHE004573R0143 semi-annually for loose terminal screws, especially in high-vibration areas. Clean dust with compressed air (max 5 bar) to maintain cooling. Calibrate input channels annually using a precision signal generator to ensure accuracy—follow ABB’s calibration procedure outlined in the user manual. If communication errors occur, check Profibus termination resistors and verify baud rates match the network. For faulty channels, swap the module with a spare to isolate issues; replace with genuine ABB parts to maintain performance. Log drift trends over time to schedule preventive maintenance before accuracy degrades.

Service and guarantee commitment

ABB provides a 3-year warranty for the UFC760BE143 3BHE004573R0143, covering defects in materials and workmanship. This includes free replacement of faulty modules and access to ABB’s global technical support team, available 24/7 for troubleshooting via phone, email, or online chat.

Customers benefit from ABB’s extensive library of technical resources, including downloadable manuals, calibration guides, and application notes. Optional on-site support is available for commissioning and troubleshooting, ensuring seamless integration into existing systems. ABB guarantees spare parts availability for 10 years post-production, minimizing long-term obsolescence risks. This commitment reflects ABB’s confidence in the UFC760BE143 3BHE004573R0143’s durability and its dedication to maximizing customer uptime in critical process applications.