Description

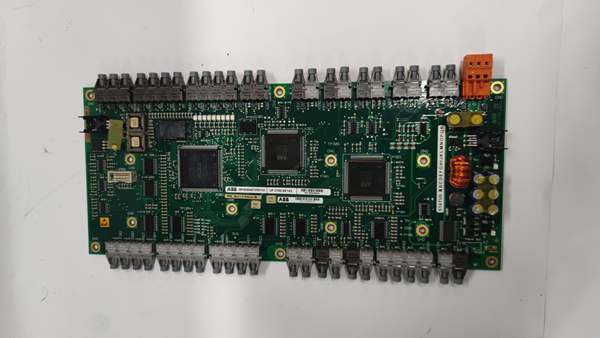

ABB UFC760BE143 3BHE004573R0143: Product Overview

The ABB UFC760BE143 (order code: 3BHE004573R0143) is a high-performance industrial control module from the UFC Series, designed for integration into ABB’s distributed control systems (DCS) and programmable logic controllers (PLCs). As a core component in process automation architectures, it combines signal conditioning, real-time control, and multi-protocol communication to manage critical industrial processes—such as motor speed regulation, temperature control, and pressure monitoring.

Engineered for harsh industrial environments, the UFC760BE143 features a ruggedized design with extended temperature tolerance and electromagnetic interference (EMI) shielding. It is typically deployed in power generation, chemical processing, and oil & gas facilities, where stable, high-speed control is essential. The module supports ABB’s advanced control algorithms (e.g., PID, fuzzy logic) and integrates seamlessly with ABB Ability™ System 800xA, AC 800M DCS, and third-party systems via open protocols.

ABB 3BHE004573R0143 UFC760BE143

ABB UFC760BE143 3BHE004573R0143: Technical Specifications

-

Model Number: UFC760BE143

-

Order Code: 3BHE004573R0143

-

Manufacturer: ABB Ltd.

-

Product Type: Industrial Control Module (DCS Controller/Interface Unit)

-

Series: UFC Series (Universal Frequency Converter/Control Modules)

-

Processor: 32-bit RISC, 1 GHz

-

Memory:

-

RAM: 512 MB (expandable via SD card)

-

Flash: 4 GB (user program/storage)

-

-

I/O Capacity:

-

Analog Inputs: 8 channels (4–20mA/0–10V/RTD/TC, configurable)

-

Analog Outputs: 4 channels (4–20mA/0–10V, 0.5A max)

-

Digital I/O: 16 channels (24VDC, sink/source mode)

-

-

Communication Interfaces:

-

2x Ethernet ports (10/100/1000 Mbps, RJ45)

-

1x Profibus DP V1 (RS485, 12 Mbps)

-

1x USB 2.0 (programming/diagnostics)

-

-

Protocol Support: Profibus DP, Modbus TCP/IP, EtherNet/IP, IEC 61850, ABB AC500/AC800 communication protocols

-

Power Supply: 24VDC (±20%, 5W max consumption)

-

Operating Temperature: -40°C to +70°C (-40°F to 158°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F)

-

Humidity Resistance: 5–95% non-condensing

-

Protection Rating: IP65 (front panel), IP20 (rear)

-

Dimensions: 180mm (H) x 120mm (W) x 80mm (D) (DIN rail mountable)

-

Weight: ~1.2 kg (2.65 lbs)

-

Certifications: CE, UL/cUL Listed, RoHS, ATEX Zone 1/2 (optional), IEC 61508 (SIL 2/3)

ABB 3BHE004573R0143 UFC760BE143

Core Features & Customer Value

-

High-Speed Processing: 1 GHz processor and 512 MB RAM enable real-time execution of complex control algorithms (e.g., cascade PID loops, motion control) with scan times <5 ms, critical for high-dynamic processes like turbine speed regulation.

-

Multi-Protocol Communication: Dual Ethernet ports and support for Profibus DP, Modbus TCP/IP, and IEC 61850 simplify integration with legacy and modern systems (e.g., Siemens S7 PLCs, Schneider SCADA), reducing network complexity.

-

Rugged Environmental Resilience: Operating temperature range (-40°C to +70°C) and IP65 rating (with sealed enclosure) enable deployment in outdoor or washdown areas (e.g., chemical plants, marine platforms). Optional ATEX certification supports explosive atmospheres.

-

Modular I/O Flexibility: 8AI/4AO/16DI/O channels can be expanded via ABB’s S800 I/O modules, adapting to growing process needs (e.g., adding sensors to a distillation column).

-

Redundant Operation: Supports hot-swappable redundant CPUs and power supplies (when paired with ABB’s redundancy kit), ensuring zero downtime in critical applications like power plant boiler control.

Typical Applications

The ABB UFC760BE143 is widely used in process industries requiring high-performance control:

-

Power Generation: Controls steam turbine speed, boiler pressure, and generator excitation in thermal/nuclear plants.

-

Chemical Processing: Manages reactor temperature, flow rates, and valve positions in batch/continuous processes.

-

Oil & Gas: Regulates pipeline pressure, pump speeds, and wellhead control in upstream/downstream operations.

-

Manufacturing: Drives variable frequency drives (VFDs) for motor speed control in steel mills, cement plants, and material handling systems.