Description

| Parameter name | Parameter value |

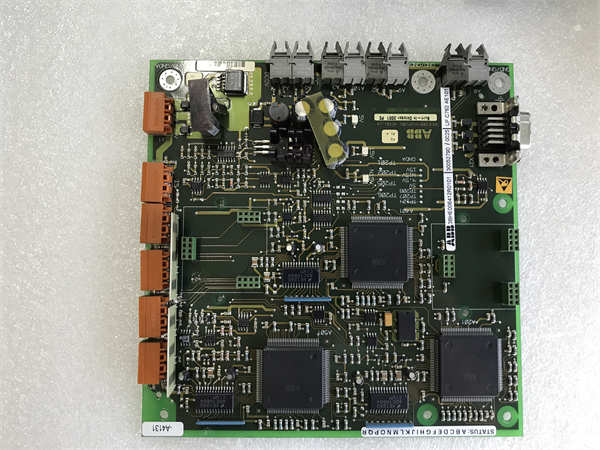

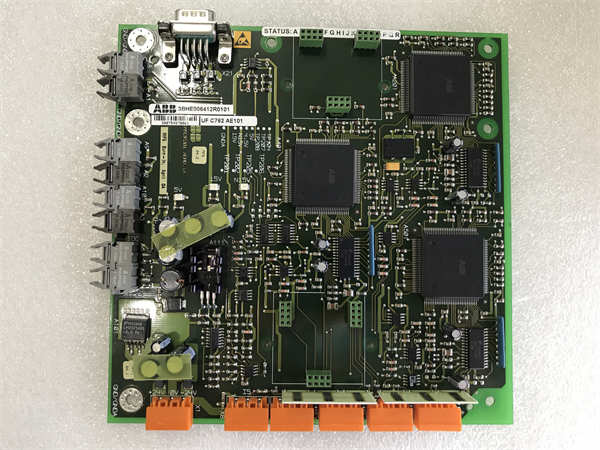

| Product model | UFC762AE101 |

| Manufacturer | ABB |

| Product category | Control motherboard, integral to ABB’s industrial control architecture for automation systems |

| Processor | 32 – bit, enabling rapid data processing for real – time control operations |

| Input voltage | Accepts 24 V DC or 100 – 240 V AC, providing flexibility in power supply options |

| Input signals | Supports analog inputs (e.g., 0 – 5V, 1 – 5V with load resistance ≥ 200KΩ; 0 – 20mV, 0 – 1V with input impedance ≥ 5MΩ) and digital inputs (ON/OFF states) |

| Output signals | Offers analog outputs (0 – 5V, 1 – 5V with load resistance ≥ 200KΩ; 0 – 10mA with load resistance ≤ 1000Ω, 4 – 20mA, 0 – 20mA with load resistance ≤ 500Ω) and digital outputs (e.g., relay with 220VAC/2A or 24VDC/2A contact capacity; SSR drive with 12VDC/30mA for solid – state relays) |

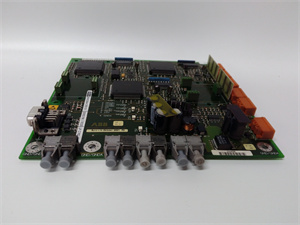

| Communication interfaces | Built – in Ethernet for high – speed network connectivity, USB for device – level connection, and supports up to 8 sets of RS232/RS485 for versatile serial communication with a variety of devices |

| Operating temperature | Can function within the range of – 20°C to + 60°C, suitable for diverse industrial environments |

| Dimensions (LxWxH) | 90mm x 36mm x 115mm or 170mm x 105mm x 32mm (varies based on specific design and application requirements) |

| Mounting method | DIN 35 – rail mounting for easy installation in standard industrial enclosures |

| Protection class | IP20, providing protection against solid objects larger than 12mm and limited protection against vertical dripping water |

ABB UFC762AE101

Product introduction

The UFC762AE101 from ABB is a high – performance control motherboard designed to play a pivotal role in industrial automation systems. As an integral part of ABB’s extensive product portfolio for industrial control, it combines advanced technology with rugged construction to meet the demands of modern industrial processes.

This motherboard is engineered to control and monitor various industrial parameters such as temperature, pressure, and flow rate. It acts as a central hub, receiving signals from sensors, processing them using its 32 – bit processor, and then generating appropriate control signals for actuators. With its modular design, the UFC762AE101 can be easily integrated into existing systems or scaled up for more complex applications. Whether in a small – scale manufacturing unit or a large – scale industrial plant, the UFC762AE101 ensures seamless operation and precise control, enhancing overall system efficiency.

Core advantages and technical highlights

High – performance processing: The 32 – bit processor on the UFC762AE101 enables rapid data processing. This allows for real – time control adjustments, ensuring that industrial processes run smoothly. For example, in a chemical plant where reaction rates need to be precisely controlled, the motherboard can quickly analyze sensor data and adjust actuator settings, maintaining optimal reaction conditions.

Versatile communication capabilities: With built – in Ethernet, USB, and multiple RS232/RS485 ports, the UFC762AE101 can communicate with a wide range of devices. It can integrate with enterprise networks via Ethernet for remote monitoring and control, while the serial ports enable connection to legacy devices or specialized sensors. In a power generation facility, it can communicate with smart meters (using RS485) and transfer data to a central control station over Ethernet.

Reliable operation in harsh environments: Rated for an operating temperature range of – 20°C to + 60°C and with an IP20 protection class, the UFC762AE101 can withstand the rigors of industrial settings. In a steel mill, where high temperatures and dust are prevalent, the motherboard continues to function reliably, ensuring uninterrupted control of the production process.

Flexible input and output options: The motherboard supports a variety of analog and digital input and output signals. This flexibility allows it to interface with different types of sensors and actuators. In a water treatment plant, it can receive analog signals from pH sensors and output analog control signals to dosing pumps, precisely regulating the chemical treatment process.

Typical application scenarios

In industrial manufacturing, the UFC762AE101 is used for controlling production lines. It can manage the speed and operation of conveyor belts, ensuring smooth material flow. For instance, in an automotive assembly plant, it controls the movement of parts along the assembly line, coordinating with robotic arms to pick and place components accurately.

In the energy sector, such as in oil refineries, the UFC762AE101 monitors and controls critical processes. It receives data from pressure sensors in pipelines and adjusts valve positions to maintain optimal flow rates. This helps in preventing leaks and ensuring efficient oil transportation.

In environmental control systems, like those in large – scale greenhouses, the motherboard plays a crucial role. It receives input from temperature, humidity, and light sensors and controls ventilation fans, irrigation systems, and shading devices. This ensures that the greenhouse environment remains optimal for plant growth.

ABB UFC762AE101

Related model recommendations

UFC761AE101: A related control board in the same series, with a slightly different configuration of input/output channels. It may be suitable for applications with fewer sensor or actuator requirements, such as small – scale laboratory automation setups.

PM864: ABB’s DCS controller that can be integrated with the UFC762AE101. The PM864 provides overall system control, while the UFC762AE101 handles local input/output and control functions in a distributed control architecture.

CI854: A PROFIBUS DP communication module that can enhance the communication capabilities of the UFC762AE101. It allows the motherboard to communicate with PROFIBUS – compatible devices, expanding its reach in industrial networks.

DI810: A 16 – channel digital input module that can be connected to the UFC762AE101 to increase the number of digital input signals it can handle. This is useful in applications where there are numerous digital sensors, such as in a security – monitoring system for an industrial facility.

AO820: An 8 – channel analog output module that pairs well with the UFC762AE101. It can be used to control analog – controlled actuators, such as variable – speed drives in a manufacturing process.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the UFC762AE101, ensure that the installation environment meets the specified temperature and humidity requirements. Use a DIN 35 – rail for mounting, and make sure the rail is securely fixed in the enclosure. Prepare ESD – safe tools to avoid electrostatic discharge damage to the motherboard during handling. Verify the power supply voltage (either 24 V DC or 100 – 240 V AC) and ensure it is stable.

Commissioning: Power on the UFC762AE101 and configure the communication settings, such as IP addresses for Ethernet and baud rates for serial ports. Calibrate the input and output channels using appropriate calibration tools. Connect sensors and actuators and test the control functions. For example, if connected to a temperature sensor, check if the motherboard accurately reads the temperature and controls the corresponding heating or cooling device.

Maintenance suggestions: Regularly check for loose connections on the motherboard. Inspect the enclosure for any signs of dust or moisture ingress, as these can affect performance. Periodically update the firmware of the UFC762AE101 to ensure optimal functionality and security. In case of a malfunction, use the diagnostic tools available (if any) to identify the problem. Replace faulty components with genuine ABB parts to maintain the integrity of the motherboard.

Service and guarantee commitment

ABB stands behind the UFC762AE101 with a comprehensive service and guarantee commitment. The product comes with a standard warranty period, during which ABB will replace any defective units free of charge. ABB’s global technical support team is available 24/7 to assist customers with any technical issues. Whether it’s a problem with installation, configuration, or operation, customers can rely on ABB’s expertise.

In addition, ABB provides access to online resources such as detailed user manuals, technical documentation, and software updates. This ensures that customers can make the most of the UFC762AE101‘s features and keep their systems up – to – date. ABB’s commitment to quality and customer satisfaction is evident in its after – sales service, giving customers peace of mind when investing in the UFC762AE101 for their industrial control needs.