Description

Detailed parameter table

| Parameter name | Parameter value |

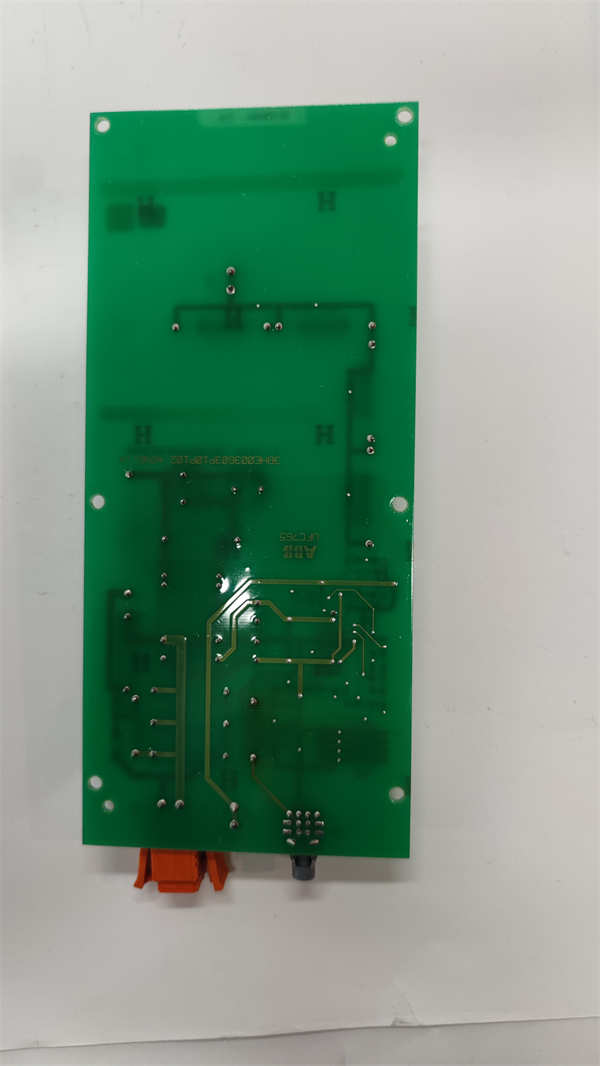

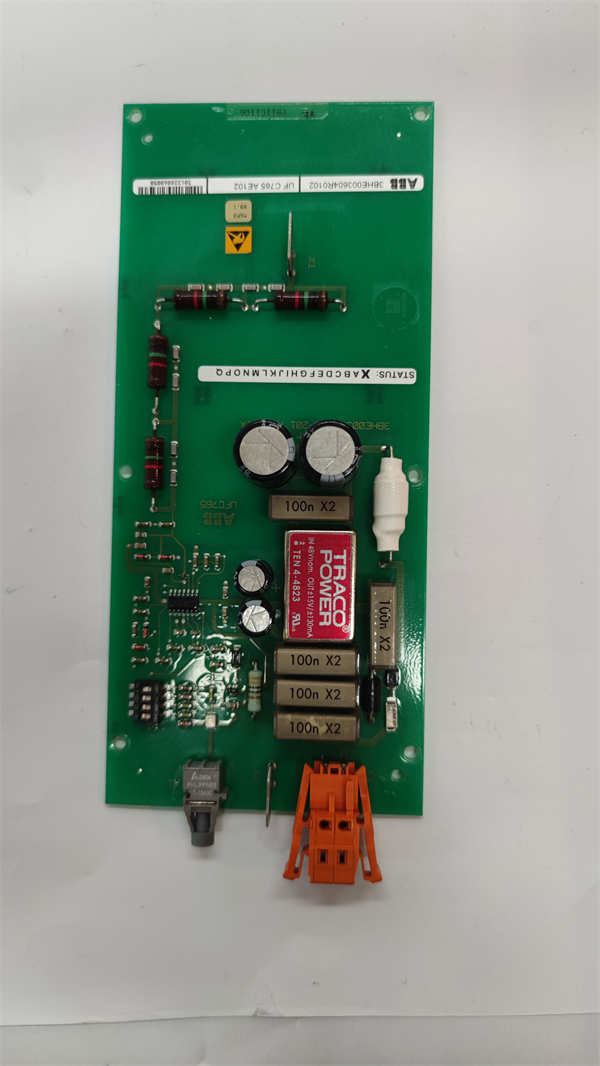

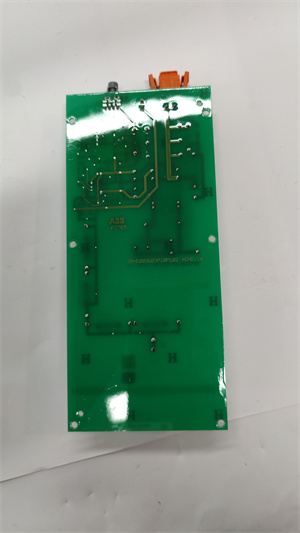

| Product model | UFC765AE102 3BHE003604R0102 |

| Manufacturer | ABB |

| Product category | Fault – Locating Indicator (FLI) Board for Electric Arc Furnaces (EAFs) and Industrial Networks |

| Supply voltage | 24 VDC |

| Power consumption | 5 W |

| Number of channels | 3 |

| Input current range | 0 – 10 A |

| Output voltage range | 0 – 5 V |

| Communication protocol | Masterbus 300 (for network – related applications) |

| Number of Masterbus 300 nodes | Up to 16 |

| Fault types detected | Grounding faults, phase – to – phase faults, open circuits (in EAF secondary circuit); open circuits, short circuits, ground faults (in Masterbus 300 network) |

| Operating temperature range | – 20 °C to + 80 °C |

| Storage temperature range | – 40 °C to + 85 °C |

| Dimensions (LxWxH) | 45.3 cm x 12.8 cm x 4.8 cm |

| Weight | 1.18 kg |

| Mounting type | Designed for easy installation within control cabinets or relevant equipment |

| Protection class | Conformal coated for enhanced protection in harsh environments |

| Hot – swappable | Yes |

ABB UFC765AE102 3BHE003604R0102

Product introduction

The ABB UFC765AE102 3BHE003604R0102 is a highly specialized and versatile fault – locating indicator (FLI) board. It serves two primary critical functions in industrial settings, particularly in the context of electric arc furnaces (EAFs) and industrial communication networks.

In the domain of EAFs, this board plays a pivotal role in ensuring the smooth operation of the secondary circuit. It is designed to detect and precisely locate faults such as grounding faults, phase – to – phase faults, and open circuits within the EAF secondary circuit. By constantly monitoring the condition of this circuit, it can preemptively provide alarms for potential faults, allowing operators to take corrective action before significant disruptions occur. This is crucial in EAF operations, where any unforeseen electrical faults can lead to production delays, equipment damage, and safety hazards.

Simultaneously, as part of the ABB Advant Master process control system, the UFC765AE102 is utilized to identify and locate faults in the Masterbus 300 communication network. In industrial automation setups, a seamless communication network is the backbone of efficient operation. The ability of this board to detect various network faults, including open circuits, short circuits, and ground faults, and to pinpoint the specific device causing the fault, is essential for maintaining the integrity of the overall control system. Its hot – swappable feature further enhances system availability, as it can be replaced without the need to shut down the entire system, minimizing downtime.

Core advantages and technical highlights

High – precision fault detection: The UFC765AE102 is engineered with advanced sensing technology that enables it to detect even the most subtle electrical anomalies. In EAF applications, it can distinguish between different types of faults in the secondary circuit with a high degree of accuracy, ensuring that the root cause of a problem is quickly identified. In the Masterbus 300 network, it can detect faults down to the level of individual devices, facilitating targeted troubleshooting and reducing the time spent on network diagnostics.

Wide operating temperature range: With an operating temperature range spanning from – 20 °C to + 80 °C, this board can function reliably in a diverse range of industrial environments. Whether it’s installed in a cold storage facility adjacent to an EAF or in a hot, humid industrial plant where the Masterbus 300 network is deployed, the UFC765AE102 maintains its performance. This resilience to extreme temperatures reduces the need for additional climate – control measures in many installations, leading to cost savings.

Conformal coating for harsh environments: The conformal coating on the board provides an extra layer of protection against dust, moisture, and chemical contaminants. In industrial settings, especially those near EAFs where there may be a significant amount of particulate matter in the air, or in areas with exposure to industrial chemicals, this coating ensures the long – term reliability of the board. It helps prevent corrosion and short – circuits that could otherwise be caused by environmental factors, extending the board’s lifespan.

Hot – swappable design: The hot – swappable feature of the UFC765AE102 is a game – changer for system maintenance. In both EAF and industrial network setups, downtime can be extremely costly. With this board, technicians can replace a faulty unit without disrupting the ongoing operation of the EAF or the Masterbus 300 network. This not only reduces production losses but also allows for more flexible maintenance scheduling, as repairs can be carried out during normal production hours.

ABB UFC765AE102 3BHE003604R0102

Typical application scenarios

In electric arc furnace operations, the UFC765AE102 is an integral part of the electrical control system. For example, in a steel – making plant that uses EAFs to melt scrap metal, the board continuously monitors the secondary circuit. If a grounding fault occurs due to wear and tear of insulation in the cables connecting the furnace electrodes, the UFC765AE102 quickly detects it. It then sends an alarm to the control room, and the operators can take immediate action, such as shutting down the affected section of the circuit for repair. This prevents the fault from escalating and potentially damaging the expensive furnace equipment.

In industrial automation plants that rely on the Masterbus 300 communication network for control and monitoring, the UFC765AE102 ensures network integrity. Consider a large – scale manufacturing facility where multiple production lines are controlled by a central PLC system connected via the Masterbus 300 network. If a short circuit occurs in one of the network cables due to mechanical damage, the UFC765AE102 detects the fault. It not only identifies the location of the short circuit but also pinpoints the device that may have contributed to the problem. This allows maintenance teams to quickly isolate and repair the issue, minimizing the impact on production.

Related model recommendations

UFC760BE143 3BHE004573R0143: An analog input/output module that can complement the UFC765AE102 in an industrial control system. In a setup where the EAF operation also requires monitoring of analog parameters such as temperature or pressure, the UFC760BE143 can handle these inputs, while the UFC765AE102 focuses on fault detection in the electrical circuit.

CI854A: A communication module that can enhance the connectivity options in a system where the UFC765AE102 is used for network fault detection. If there is a need to integrate the Masterbus 300 network with other communication protocols or expand the network’s reach, the CI854A can be used in combination with the UFC765AE102 to achieve seamless communication.

AC800M: ABB’s modular PLC that can work in tandem with the UFC765AE102 in both EAF and industrial network applications. The PLC can process the fault data received from the UFC765AE102 and execute control logic to either shut down affected equipment safely in case of a critical fault or initiate corrective actions, such as re – routing network traffic in case of a network fault.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the UFC765AE102, ensure that the installation location is clean and free from excessive dust or moisture. For EAF – related installations, make sure the area is well – ventilated to avoid overheating. When installing in a control cabinet for Masterbus 300 network applications, verify that the cabinet has sufficient space for the board. Use appropriate ESD – safe tools and anti – static wristbands to handle the board during installation to prevent electrostatic discharge from damaging its sensitive components.

Maintenance suggestions: Regularly inspect the UFC765AE102 for any signs of physical damage, such as cracks in the conformal coating or loose connections. Check the board’s temperature during operation; if it exceeds the normal range, investigate for potential cooling issues or abnormal power consumption. Periodically clean the board with a soft, dry cloth to remove any dust that may have accumulated. If communication errors occur in the Masterbus 300 network or if there are false alarms in the EAF fault – detection system, check the board’s configuration settings and the integrity of the associated cables.

Commissioning process: After installation, power up the system and check for any error messages on the board’s status indicators. For EAF applications, calibrate the fault – detection thresholds according to the specific requirements of the EAF secondary circuit. In the case of Masterbus 300 network applications, configure the board to communicate with the network nodes. Conduct a series of test scenarios, such as simulating a short circuit in the network or a phase – to – phase fault in the EAF secondary circuit, to ensure that the UFC765AE102 is functioning correctly. Monitor the board’s response and verify that the alarms are being generated and transmitted accurately.

Service and guarantee commitment

ABB provides a 12 – month warranty for the UFC765AE102 3BHE003604R0102, covering defects in materials and workmanship. During this period, if the board fails due to manufacturing – related issues, ABB will provide a free replacement. Customers can access ABB’s global technical support network, which is available 24/7 for troubleshooting and technical advice. ABB also offers a comprehensive range of technical documentation, including user manuals, installation guides, and troubleshooting guides, to assist customers in using and maintaining the board. In addition, optional on – site support services are available for customers who require hands – on assistance during installation, commissioning, or maintenance. ABB ensures the availability of spare parts for a reasonable period after the product’s production phase, minimizing the risk of system downtime due to unavailability of replacement parts.