Description

UFC789AE101: Product Overview

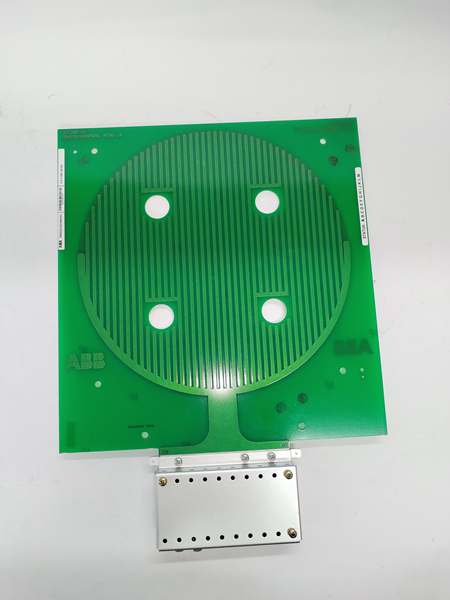

The ABB UFC789AE101 is an industrial control module designed for ABB’s AC 800M distributed control system (DCS), a flagship platform for mission-critical process automation. As a critical component of the AC 800M ecosystem, it acts as a fault-tolerant controller or FSCD-board (Field Signal Conditioning and Distribution), providing reliable signal processing, communication, and control for industries like power generation, chemical processing, and manufacturing.

Role in Automation Systems:

Positioned as a “local control node,” the UFC789AE101 bridges the gap between field devices (e.g., sensors, actuators) and the central DCS controller. It performs three primary functions:

-

Signal Conditioning: Filters and amplifies weak analog signals from field devices (e.g., 4–20 mA pressure sensors) to ensure accurate transmission to the controller.

-

Fault Tolerance: Detects and recovers from faults (e.g., overcurrent, overvoltage) to maintain uninterrupted operation of critical processes.

-

Communication Hub: Supports multiple industrial protocols (RS-485, Modbus RTU, Ethernet) to seamlessly connect with the AC 800M controller and third-party systems.

Core Functionality:

-

Fault-Tolerant Design: Features dual-core processing and triple-network redundancy (PROFIBUS, Ethernet, MODBUS) to eliminate single points of failure.

-

Wide Operating Temperature Range: Suitable for harsh industrial environments (e.g., power plants, chemical refineries) with temperatures from -20°C to +60°C.

-

Easy Integration: Plug-and-play compatibility with ABB’s AC 800M DCS reduces setup time and effort for engineers.

Platform Benefits (AC 800M Series):

The UFC789AE101 leverages ABB’s AC 800M platform, which is renowned for:

-

Scalability: Supports expansion with additional I/O modules or communication interfaces to accommodate growing operational needs.

-

Reliability: Industrial-grade components and a rugged design ensure 24/7 operation in harsh environments.

-

Diagnostic Capabilities: Built-in status LEDs and fault logging simplify troubleshooting, reducing mean time to repair (MTTR).

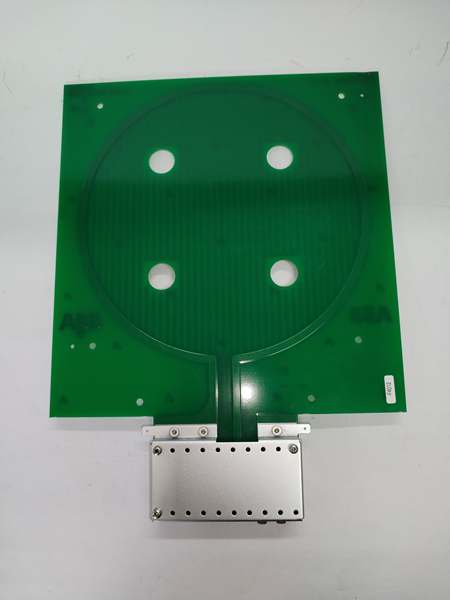

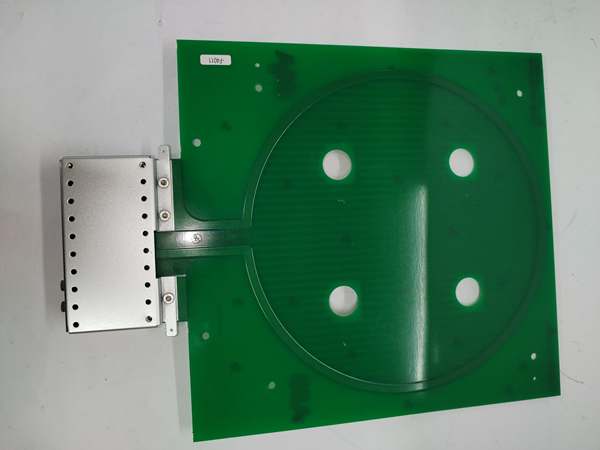

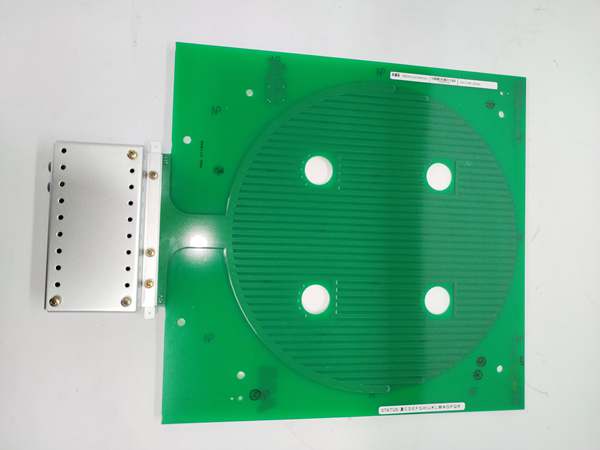

ABB UFC789AE101

Technical Specifications

Model Number: UFC789AE101

Manufacturer: ABB

Product Type: Industrial Control Module

-

Input Voltage: 24V DC (nominal)

-

Output Current: 2A (max per channel)

-

Communication Protocols: RS-485, Modbus RTU, Ethernet (10/100 Mbps)

-

Operating Temperature: -20°C to +60°C (standard); -40°C to +85°C (optional)

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5% to 95% non-condensing

-

Dimensions (W×H×D): 100 mm × 75 mm × 20 mm (3.94 in × 2.95 in × 0.79 in)

-

Weight: 0.5 kg (1.1 lbs)

-

Protection Rating: IP20 (front panel); IP30 (optional, conformal coating)

-

Certifications: CE, UL, RoHS

Core Features & Customer Value

1. Fault-Tolerant Operation:

The UFC789AE101’s dual-core processing and triple-network redundancy ensure uninterrupted operation even if one component fails. For example, in a power plant, this module can maintain control of turbine speed during a communication failure, preventing unplanned downtime.

2. Wide Environmental Tolerance:

The module’s operating temperature range (-20°C to +60°C) and optional IP30 rating make it suitable for harsh industrial environments. In a chemical refinery, this means reliable operation near high-temperature reactors or corrosive atmospheres.

3. Seamless Integration with AC 800M:

Plug-and-play compatibility with ABB’s AC 800M DCS reduces setup time and effort. Engineers can use ABB’s Control Builder M software to configure the module as part of a larger control system, simplifying system design.

4. Robust Protection:

The module’s overcurrent, overvoltage, and thermal overload protection safeguard both the module and connected devices. In a manufacturing plant, this prevents damage to sensitive control equipment from power surges.

ABB UFC789AE101

Typical Applications

The ABB UFC789AE101 is widely used in industries requiring reliable control and fault tolerance:

-

Power Generation:

-

Controls turbine speed and fuel flow in thermal power plants.

-

Example: In a coal-fired power plant, the module adjusts the speed of a turbine to maintain optimal efficiency, even during load changes.

-

-

Chemical Processing:

-

Monitors pressure and temperature in chemical reactors.

-

Example: In a petrochemical refinery, the module processes signals from a pressure sensor to adjust the flow of reactants, maintaining consistent product quality.

-

-

Manufacturing:

-

Controls conveyor belts and robotic arms in automotive assembly lines.

-

Example: In an automotive factory, the module coordinates the movement of a robotic arm to pick up a car door, synchronizing with other assembly processes.

-