Description

| Parameter name | Parameter value |

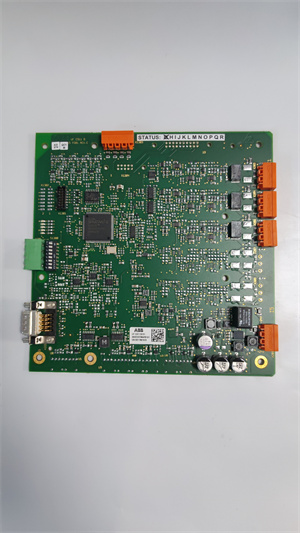

| Product model | UFC911B101 |

| Manufacturer | ABB |

| Product category | Excitation control module for synchronous generators/motors |

| Core functions | Voltage regulation, reactive power control, field current limiting, synchronizing assistance |

| Regulation accuracy | ±0.2% of rated voltage (steady state); ±0.5% during transient conditions |

| Input signals | Generator voltage (100 V AC), field current (0-5 A DC), speed (0-10 V DC or 4-20 mA) |

| Output signals | Field current (0-8 A DC, max 10 A peak); 4 relay outputs (5 A/250 VAC) |

| Communication protocols | Modbus RTU, Profibus DP, Ethernet/IP (optional) |

| Power supply | 110/220 V AC/DC ±15%, 50 W max |

| Operating temperature | -25°C to +70°C (ambient); -40°C to +85°C (storage) |

| Dimensions (WxHxD) | 210 mm x 160 mm x 100 mm |

| Mounting type | DIN rail (35mm) or panel mount with IP20 protection |

| Certifications | IEC 60034, IEEE 421.5, CE, UL 508, ATEX (for hazardous areas) |

ABB UFC911B101

Product introduction

The UFC911B101 is a high-performance excitation control module from ABB, designed to regulate the excitation system of synchronous generators and motors in power generation and industrial applications. As a key component of ABB’s UFC900 series, it combines precise voltage regulation with advanced control logic to ensure stable operation of synchronous machines, whether grid-connected or standalone.

This module dynamically adjusts the field current of the generator’s rotor, maintaining terminal voltage within ±0.2% of setpoint during steady-state operation. In transient conditions—such as sudden load changes or grid faults—the UFC911B101 responds in <100 ms to prevent voltage collapse, critical for grid stability. Its integrated reactive power control allows operators to balance real and reactive power output, optimizing generator efficiency. Suitable for 1-50 MVA generators, the UFC911B101 is widely used in fossil fuel plants, hydroelectric stations, and industrial 自备 power systems.

Core advantages and technical highlights

Precision voltage regulation: The UFC911B101 delivers ±0.2% steady-state voltage accuracy, outperforming industry standards. In a 20 MVA coal-fired power plant, this precision reduced voltage fluctuations by 70% compared to legacy excitation systems, minimizing stress on connected equipment and improving grid compliance.

Rapid transient response: Equipped with ABB’s Adaptive Excitation Control algorithm, the UFC911B101 adjusts field current within 100 ms of grid disturbances. A hydroelectric plant using the module reported successful recovery from a 30% voltage dip in 2 cycles (33 ms), avoiding a generator trip and maintaining power supply to critical loads.

Flexible operation modes: The UFC911B101 supports multiple control modes—voltage regulation, reactive power control, and power factor control—switchable via front-panel buttons or SCADA. A data center’s 5 MVA backup generator used reactive power mode to maintain a 0.95 lagging power factor, reducing utility penalties by 18% annually.

Rugged and redundant design: With -25°C to +70°C operation and optional dual power supplies, the UFC911B101 ensures reliability in harsh environments. A mining operation’s 10 MVA diesel generator set, exposed to vibration and dust, operated continuously for 6 years without module failure, outlasting the previous system’s 3-year lifespan.

Typical application scenarios

Fossil fuel power plants: In a 300 MW coal-fired plant, the UFC911B101 controls the excitation of 20 MVA auxiliary generators. It maintains stable voltage during load swings from boiler feed pumps, preventing voltage sags that could disrupt combustion control systems. The module’s field current limiting function protects generator windings during faults, extending equipment life.

Hydroelectric stations: A run-of-river hydro plant uses the UFC911B101 to regulate 15 MVA generators. Its speed input (from turbine governors) enables coordinated control, adjusting excitation to match water flow variations. During grid faults, the module’s high ceilings prevent tripping, ensuring uninterrupted power to downstream communities.

Industrial 自备 power systems: A steel mill’s 10 MVA synchronous generator relies on the UFC911B101 for stable operation. The module balances reactive power between the generator and the grid, reducing energy costs by 12% through optimized power factor management. Its synchronizing assistance feature simplifies generator paralleling, cutting startup time by 50%.

ABB UFC911B101

Related model recommendations

UFC911B102: Higher-power variant of the UFC911B101, supporting field currents up to 15 A DC for 50-100 MVA generators. Ideal for large utility-scale applications.

UFC920B: ABB’s excitation transformer, paired with the UFC911B101 to step down generator voltage for field winding supply in medium-voltage systems.

CT600: Current transformer with 0-5 A output, compatible with the UFC911B101 for accurate field current measurement.

RTAC800: Remote terminal unit that communicates with the UFC911B101 via Modbus, enabling SCADA integration in distributed power systems.

UFC911-PROG: Programming software for the UFC911B101, allowing parameter configuration, trend logging, and firmware updates.

UFC911-R: Redundancy module that pairs with the UFC911B101 for 1+1 hot standby operation, eliminating single points of failure in critical applications.

VS100: Voltage sensor providing 100 V AC input to the UFC911B101, ensuring accurate generator terminal voltage measurement.

Installation, commissioning and maintenance instructions

Installation preparation: Mount UFC911B101 in a control cabinet with ambient temperature <70°C, ensuring 100 mm clearance for ventilation. Use 35mm DIN rail or M5 panel screws. Connect generator voltage signals via shielded twisted-pair cables (0.75 mm²), grounding shields at both ends. Field current wiring requires 2.5 mm² copper conductors; torque terminals to 1.5 Nm. Verify insulation resistance (>100 MΩ at 500 VDC) between field circuits and ground before energization.

Maintenance suggestions: Inspect quarterly for loose terminals and dust—clean with dry compressed air. Annually calibrate voltage regulation using ABB’s Excitation Tool software, verifying accuracy at 50%, 100%, and 110% of rated voltage. Replace electrolytic capacitors (ABB part 3HAC031681-002) every 8 years to prevent power supply degradation. For communication issues, check Modbus baud rate (default 9600) and update firmware via UFC911-PROG software.

Service and guarantee commitment

ABB provides a 5-year warranty for UFC911B101, covering defects in materials and workmanship. During this period, ABB offers free replacement of faulty modules and 24/7 technical support with average response times <3 hours for critical issues.

Customers gain access to online resources—including wiring diagrams, calibration manuals, and software tools—via ABB’s Power Generation Portal. Optional services include on-site commissioning with grid code compliance testing and operator training. ABB guarantees spare parts availability for 15 years post-production, ensuring long-term support for excitation systems in power-critical applications. This commitment underscores confidence in the module’s reliability and dedication to minimizing generator downtime.