Description

Detailed parameter table

| Parameter Name | Parameter Value |

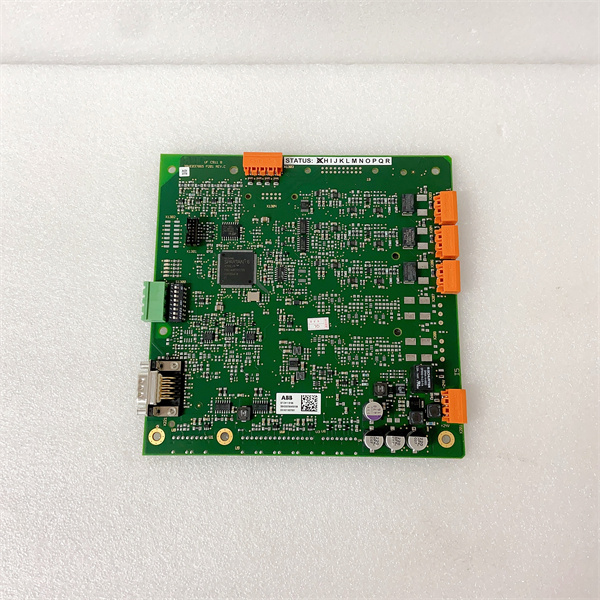

| Product model | UFC911B106 3BHE037864R0106 |

| Manufacturer | ABB |

| Product category | Field control unit (for industrial process automation and monitoring) |

| Processor | 32-bit RISC processor (500 MHz) |

| Memory | 256 MB RAM, 128 MB Flash memory |

| Input channels | 8 universal analog inputs (4-20 mA, 0-10 V, RTD, thermocouple) |

| Output channels | 4 analog outputs (4-20 mA) |

| Digital I/O | 8 digital inputs, 4 digital outputs |

| Operating voltage | 24 V DC ±15% |

| Power consumption | ≤ 12 W |

| Operating temperature | -40°C to +70°C |

| Dimensions (W×H×D) | 160 mm × 220 mm × 100 mm |

| Mounting method | DIN rail mounting (35 mm) |

| Communication protocols | Modbus RTU, Profibus DP |

| Certification | IEC 61131-2, CE, UL 508, ATEX Zone 2 |

| Compatible systems | ABB AC800M controller, UFC920B101 expansion module, CI854A communication adapter |

UFC911B106 3BHE037864R0106

Product introduction

The UFC911B106 3BHE037864R0106 is a versatile field control unit from ABB, designed to integrate and process analog and digital signals in industrial process automation systems. As a key component in distributed control architectures, it bridges field devices (sensors, actuators, transmitters) and higher-level controllers, enabling real-time data acquisition and control in complex industrial environments.

This unit combines 8 universal analog inputs, 4 analog outputs, 8 digital inputs, and 4 digital outputs in a compact enclosure, making it ideal for applications requiring mixed-signal processing. The UFC911B106 3BHE037864R0106 supports multiple sensor types (RTDs, thermocouples, 4-20 mA transmitters) without needing external signal converters, simplifying system design. Its wide operating temperature range and hazardous area certification make it suitable for oil and gas, chemical processing, and power generation facilities, where reliable performance in extreme conditions is critical.

Core advantages and technical highlights

Universal input flexibility: The UFC911B106 3BHE037864R0106 accepts multiple signal types on the same analog input channels, eliminating the need for dedicated modules. In a chemical plant, this allows the unit to simultaneously monitor:

Temperature via thermocouples (Type K) in reactor vessels

Pressure via 4-20 mA transmitters in pipelines

Level via RTDs in storage tanks

This versatility reduces inventory costs and simplifies spare parts management.

Extreme environment reliability: With operation from -40°C to +70°C and ATEX Zone 2 certification, the UFC911B106 3BHE037864R0106 thrives in harsh conditions. In an offshore oil platform’s wellhead control panel, it continues to process pressure and temperature signals accurately despite salt spray, vibration, and wide temperature swings—ensuring critical safety systems receive reliable data.

Seamless communication integration: Equipped with Modbus RTU and Profibus DP, the UFC911B106 3BHE037864R0106 connects easily to ABB’s AC800M controller and third-party systems. In a power plant’s boiler control system, it transmits real-time steam temperature data via Profibus DP to the main controller, which adjusts fuel flow—all while sending process trends to a SCADA system via Modbus RTU.

Typical application scenarios

In a natural gas processing plant’s amine treating unit, the UFC911B106 3BHE037864R0106 monitors and controls the gas purification process. Its analog inputs track amine solution temperature (via RTDs), gas flow rate (4-20 mA), and pressure (4-20 mA). Digital inputs detect valve position switches and pump run status, while analog outputs adjust control valves regulating amine flow.

The unit communicates via Profibus DP with the AC800M controller, enabling closed-loop control of the absorption tower’s operating parameters. In this hazardous environment, the UFC911B106 3BHE037864R0106‘s ATEX certification ensures safe operation, while its wide temperature tolerance handles the facility’s ambient fluctuations from -10°C in winter to +50°C in summer.

Related model recommendations

UFC920B101: Expansion module for UFC911B106 3BHE037864R0106 adding 8 more analog inputs.

CI854A: Profibus DP communication adapter that enhances data transfer between UFC911B106 3BHE037864R0106 and AC800M.

UFC912B102: Digital-only variant of UFC911B106 3BHE037864R0106 for applications needing more discrete I/O.

TB820V2: Terminal base for UFC911B106 3BHE037864R0106 providing secure field wiring connections.

AC800M PM864: Controller that integrates with UFC911B106 3BHE037864R0106 for advanced process control.

UFC930B103: High-density analog output module compatible with UFC911B106 3BHE037864R0106 for larger systems.

UFC911B106 3BHE037864R0106

Installation, commissioning and maintenance instructions

Installation preparation: Mount the UFC911B106 3BHE037864R0106 on a 35 mm DIN rail in a control cabinet with proper ventilation. Ensure the cabinet is sealed against dust and moisture in harsh environments. Use shielded twisted-pair cable (0.5-1.5 mm²) for all field connections, grounding shields at the unit end. Connect 24 V DC power with a 1.5 A fuse, verifying correct polarity. For hazardous areas, ensure installation complies with ATEX Zone 2 requirements, including proper cable gland sealing.

Maintenance suggestions: Inspect the UFC911B106 3BHE037864R0106 quarterly for loose terminals or corrosion, especially in humid or coastal environments. Calibrate analog channels annually using a precision signal generator to maintain accuracy within ±0.1% of full scale. Clean ventilation slots with compressed air to prevent overheating. If communication faults occur, check protocol settings and cable continuity before replacing the unit. Update firmware annually using ABB’s Control Builder M software. Replace only with ABB-approved units to maintain certification and performance.

Service and guarantee commitment

The UFC911B106 3BHE037864R0106 is backed by a 2-year warranty covering defects in materials and workmanship under normal operating conditions. ABB’s process automation technical support team provides specialized assistance for system integration, including calibration guidance and protocol configuration.

Customers receive access to detailed technical documentation, including wiring diagrams and calibration procedures specific to the UFC911B106 3BHE037864R0106. ABB maintains a global inventory of replacement units to minimize downtime in critical processes. Our service network offers on-site support for commissioning and troubleshooting, ensuring optimal performance throughout the product’s lifecycle.